Simple mechanical steps automatically position empty bottles upright on an infeed conveyor. Here’s how.

December 9, 2022

Bottle orienters are used to unload bottles supplied in bulk in a box or bag onto on a conveyor and standing upright. There are six to eight common types of operations to do this. One, for example, uses a hook to orient the bottles. Hook orienters have the advantage of high speed, mechanical simplicity, and an ability to work well on different bottle sizes and styles.

Most bottle orienters start with a hopper into which bottles are dumped. Hoppers should be at floor level for ease of loading. They should be sized to hold multiple bags or boxes of bottles. This reduces the need for constant operator attention.

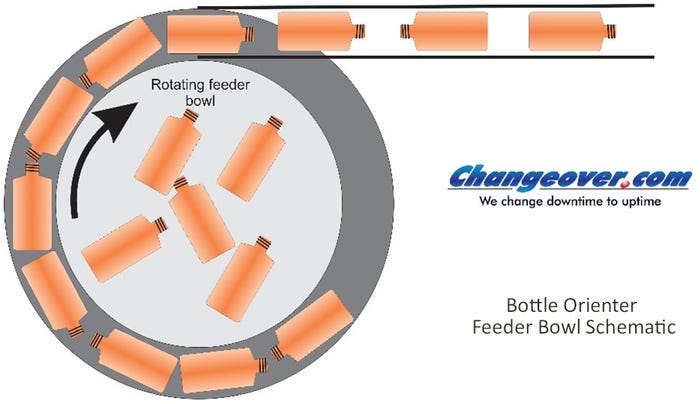

The hopper discharges the bottles into a bowl feeder. This consists of a rotating plastic disk at the bottom of a bowl. The disk has a step or channel in the outer edge slightly larger than the bottle diameter. Stationary guides and sometimes motorized paddles guide the bottles into the channel lengthwise.

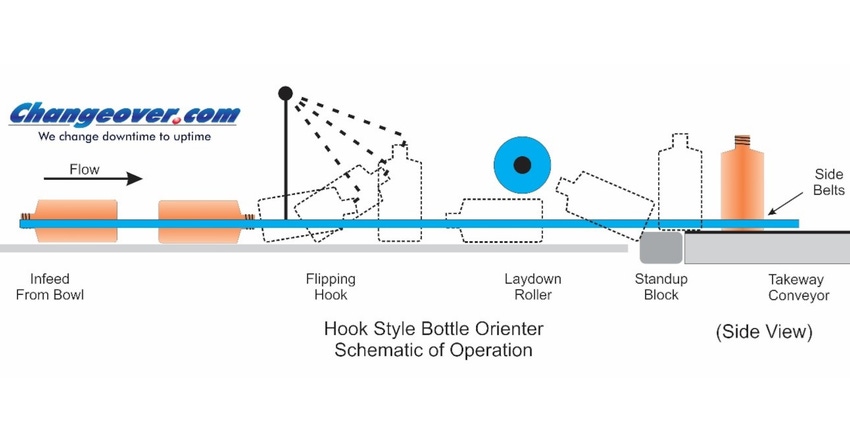

Bottles exit tangential to the disk. At this point they are all horizontal, long dimension with flow and neck leading or trailing at random. Side belts, running slightly faster than the disk, capture the bottles as they exit. The increased speed creates a gap between bottles. (See image at top of page.)

The side belts carry the bottle into a spring-loaded hook. If neck leading, the hook catches it, pulling it over as the bottle goes past. A roller lays it down neck trailing. When the base is leading, the hook rides over it, letting it continue through without any change in orientation.

Bottles then are carried into the standup block. This trips them upright for the next packaging step.

It’s easy when you know.

Find out more about bottle orienting, cleaning, and line loading. It’s all in Chapter 2 of my Packaging Machinery Handbook. Other chapters cover filling, flexible packaging, coding, and all commonly used packaging machinery. The complete table of contents and chapter samples can be found at http://www.packmachbook.com/handbooksample.pdf. Purchase the Handbook on Amazon at https://amzn.to/3kr4qj7.

About the Author(s)

You May Also Like