In advance of interpack 2023, Echo Machinery reintroduces itself to the world with a video tour of its massive, new flagship packaging machinery and headquarters facility.

March 8, 2023

Sponsored by Echo Machinery

Echo Chang

The packaging industry is getting back to normal, evidenced by the return of in-person trade shows, evidenced by the return of interpack this May in Düsseldorf, Germany, after a long pandemic-related hiatus (as reported in this Packaging Digest article). Packaging professionals will reintroduce themselves to solution providers and perhaps meet some for the first time – including Echo Machinery.

In turn, Echo, based in China and formally known as Wenzhou Echo Machinery Co., seeks to reintroduce itself to the industry at interpack (Hall 1 / A76). The company focuses on providing packaging machines along with related materials and process technology to customers worldwide.

More than a million square feet

The big news is that the company, founded in 2000, began production in January 2022 at its new $30-million headquarters site in the Zhixin Industrial Area of Rui’an in the eastern, coastal province of Zhejiang, China.

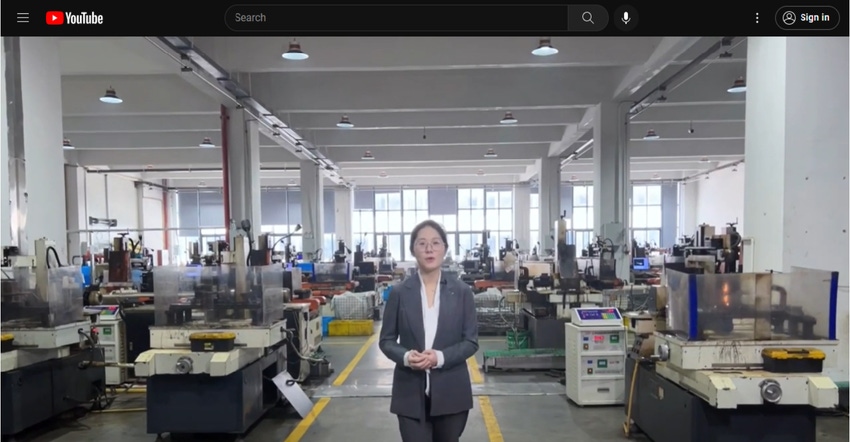

The eight-story facility totals 98,000 square meters (about 1.05 million square-feet), about a third of which is dedicated to production. The company reports scientific arrangement of R&D raw material processing, assembly, commissioning, storage, and logistics processes and assets. Below: Click to watch a video tour of the facility, floor-by-floor:

First floor: Exhibition hall, processing, and distribution

Second floor: Warehousing

Third floor: Machine assembly workshop

Fourth floor: Debugging workshop

Fifth floor: Exhibition and conference hall

Sixth to eight floors: Offices

The company's blog provides more details in writing, floor by floor. This includes a close-up view, for example, of its $6.3-million, 200-employee machining center, which encompasses 21 machining centers, 32 CNC lathes, and 10 drilling centers. This along with assets and processes on each floor are highlighted in an 11-minute video tour:

Echo is one of the largest packaging machinery manufacturers in China, and serves companies worldwide in all sectors including food, beverage, confectionery, bakery, pharmaceutical, cosmetics, nonfood and industrial goods. Machines include several types tailored for various forms of premade pouch packaging; vacuum packing; quad-seal bag packing; horizontal and vertical form-fill-seal; gravity liquid filling; piston liquid filling; and spout filling and capping.

The company also offers automatic tray sealing machines and a range of ancillary equipment from conveyors to coders and automated controls for its offerings.

In addition to high levels of integration and efficiency for manufacturing, sustainability and energy savings figure prominently at the new plant. Currently, 6,000 square meters of solar panels are planned for installation on the factory's roof, which are expected to produce 1.15 million kWh of power. Surplus energy will be incorporated into the State Grid for use in the surrounding community and help cut carbon emissions by 1,136 tons annually.

The new location, according to Echo Chang, CEO, “not only allows us to implement the green plan we have cherished for a long time; it provides an opportunity for us to bring more jobs to the area.” He added that the new factory will provide more than 200 high-wage, local jobs.

With a 22-year history specializing in packaging machines, Echo Machinery was founded in 2000. It employs 600 people, including 50 seasoned R & D experts, and is the national standard-setter for automatic prepared bag packaging machines. It is one of the largest producers of packing machines in China.

About the Author

Echo Chang, CEO of Echo Machinery, has been serving in the packaging machinery sector for 20 years. For more information, visit Echo Machinery at www.echomachinery.com; via text or phone at +86 13705877606; or via email at [email protected]

Echo Chang, CEO of Echo Machinery, has been serving in the packaging machinery sector for 20 years. For more information, visit Echo Machinery at www.echomachinery.com; via text or phone at +86 13705877606; or via email at [email protected]

You May Also Like