May 3, 2017

Amniox taps the unique properties of placental tissue to develop a range of regenerative products. “The fetal environment is unique in human nature—it has anti-inflammatory properties, enabling fetal tissue to heal and regenerate when compromised,” explains Tom Dugan, CEO of Amniox. Such findings became evident to Dr. Scheffer C. G. Tseng, MD, PhD, back in the '80s, when he began research under what has since become a continuous NIH grant. He has worked ever since as Amniox parent TissueTech chief scientific officer to transform donated umbilical cords, placentas, and other tissues into products for wound care, pain management, ophthalmology and orthopedic therapies, and other uses.

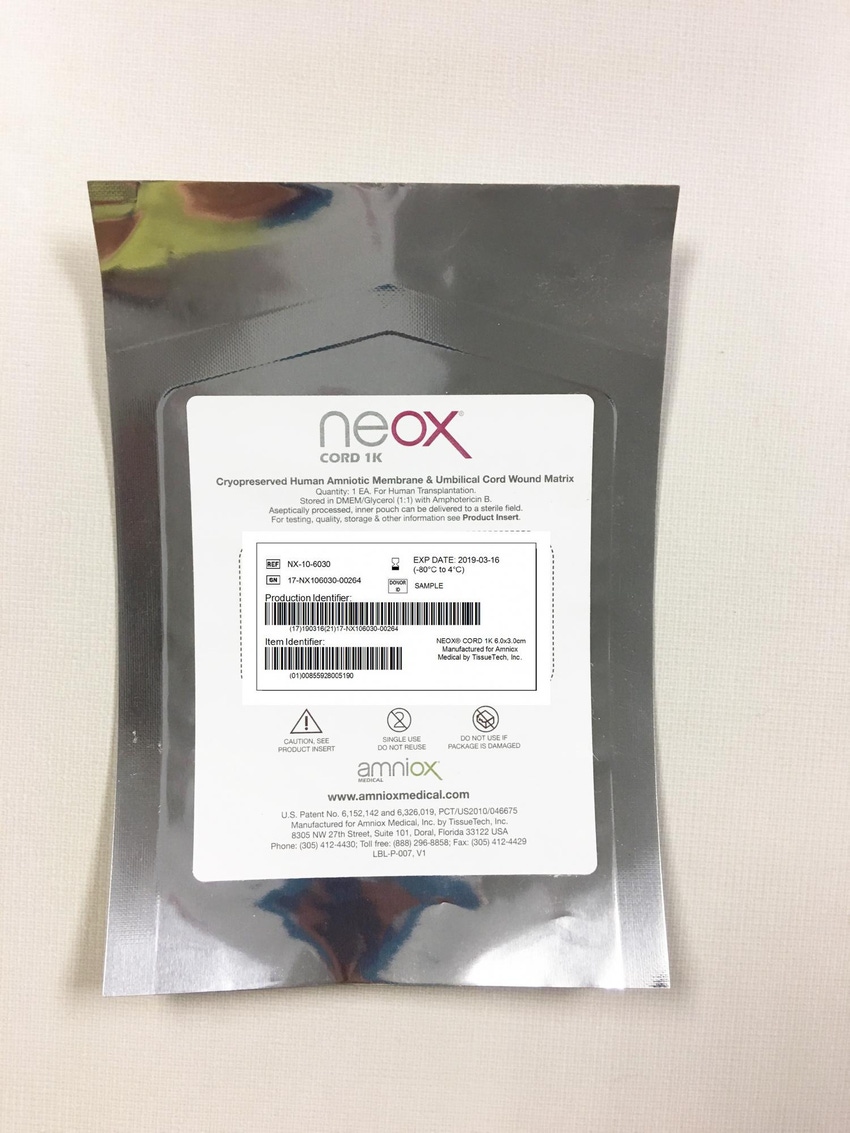

Specialized cryopreservation and packaging processes are central to maintaining the tissue’s regenerative biology as well as its structure, Dugan tells PMP News. “We’ve always been cryopreserving tissue. The process keeps it as close to fresh tissue as possible,” he says.

Amniox is a subsidiary of TissueTech, which Amy Tseng, MBA, CPA, founded in 1997. Another subsidiary, Bio-Tissue, develops and markets ophthalmology products from amniotic tissue. Together these AATB-compliant entities function as an accredited tissue bank, and work with health institutions and other tissue banks to harvest and recover donated tissues from live Caesarean births.

Dr. Tseng developed the CryoTek cryopreservation process in the early 1990s. The patented process “utilizes deep freezing to preserve the functional and structural integrity of the tissues while maintaining their natural hydrated state,” according to the company.

Dugan explains that the proprietary process meets FDA regulations for HCTP 361 tissue. “We have shown that we minimally manipulate the placental tissue,” he says. “We make sure that the cells are devitalized and no longer living, but still retain the essential biological components.” The process preserves heavy-chain hyaluronic acid and PTX3 components, for instance, which play a role in tissue regeneration.

“Other forms of processing requiring dehydration of the matrix degrade this critical biology and may limit the tissue’s capabilities,” according to Dugan.

The tissue is handled aseptically throughout the cryopreservation process and placed into double sterile barrier pouches with a glycerol solution. For instance, the NEOX Wound Matrix and CLARIX Regenerative Matrix products are packaged in a poly peel pouch sealed within a poly/foil outer peel pouch.

All products are shipped using NanoCool technology for delivery within 24 hours. If needed, however, such transport means has been validated to be a temperature-controlled environment for up to 96 hours during shipping.

Cryopreserved products can be stored in Amniox-provided freezers, and Dugan says they don’t require an extensive process for thawing. “They can be ready for use in minutes,” he says. And “the CryoTek process allows products to be taken out of the freezer for up to 6 hours and then be put back in if needed. We’ve qualified and validated this.”

“With other products that are cryogenically processed, users have to be careful—once they are taken out, they have a very short shelf life before they must be placed back in a deep freezer,” Dugan adds.

The Amniox proprietary cryopreserved products thaw at room temperature in their original unopened packaging in less than 10 minutes. To open the inner pouch, clinicians peel above the seal line, or use sterile scissors to cut below the seal line. Sterile smooth forceps or gloves are used to remove the inner peel-pouch and introduce it to the sterile field. Then the clinician removes the matrix using smooth sterile forceps.

Amniox offers several different amniotic tissue-based products. “All products start with the basic cryopreservation process and then are further processed differently,” says Dugan.

Above: Another view of packaged NEOX tissue. Image courtesy of Amniox.

NEOX CORD 1K, CLARIX CORD 1K, and NEOX CORD RT, for instance, are immediately ready for transplantation once removed from the sterile packaging. The CRYOTEK and STERITEK preservation processes allow the tissue to maintain hydration, and the optimized thickness provides easy handling and suturing of the tissue. According to Dugan, “No other preservation technologies offer the convenience of the Amniox products, whether in a cryopreserved or terminally sterilized state.”

The NEOX 100 Wound Matrix and CLARIX 100 Regenerative Matrix are affixed to carrier paper, from which they must be removed prior to use. The Quick-Peel backing is split, thereby offering two flaps for optimized handling and controlled delivery. To apply a NEOX 100 Matrix or CLARIX 100 Matrix, clinicians locate the flaps on the paper backing, peel apart the flaps, place with the adhesive side towards the defect, and dispose of the paper backing.

Amniox does also offer a room-temperature product that is packaged in saline and terminally sterilized. Unlike other room-temperature placental products, “it is not dehydrated,” says Dugan. "This technology is also proprietary and the ability to provide a terminally sterilized hydrated product is unique to Amniox."

A lyophilized version of amniotic tissue is also available in powder form for reconstitution for injection or direct wound application.

Amniox is also developing a new gel-based product packaged in a tube.

“Our products have been recognized as easy to use in the end-use environment,” says Dugan. “We have had more than 250,000 implantations with no adverse events. Our packaging solution enables us to maintain all the work we’ve done.”

************************

Eager to learn more about cutting-edge technologies in medtech and drug delivery? Check out these presentations planned June 13-15 at Medical Design & Manufacturing East in New York City:

Edible Electronics: Custom IC Design Enables Ingestible Sensors

Speaker: Andrew Kelly (Cactus Semiconductor)

Case Study: Disruptive Design Strategy for Your Next Combination Product

Speaker: Jim Warner (JW3D, Inc.)

Design Your Labeling Like You Design Your Device

Speaker: Michael Drues (Vascular Sciences)

Case Study: Selecting Sensors to Improve Device Performance

Speaker: John Pocreva (Mannkind Corporation)

To Err Is Human, but How Do You Prevent It?

Speaker: Michael Wiklund (UL LLC, Wiklund R&D)

Advantages of DuPont Delrin Acetal Homopolymer in Medical and Drug Delivery Devices

Speaker: David J. Spritzer (DuPont Performance Materials)

Panel: Design Planning - Why an Ounce of Prevention Is Worth a Pound of Cure

Moderator: Himanshu Naik (Bristol-Meyers Squibb)

Panelists: Tina Lochner (Medcert-USA, LLC), Darin Oppenheimer (Merck), Richard Chamberlain, PhD (The FDA Group, LLC)

About the Author(s)

You May Also Like