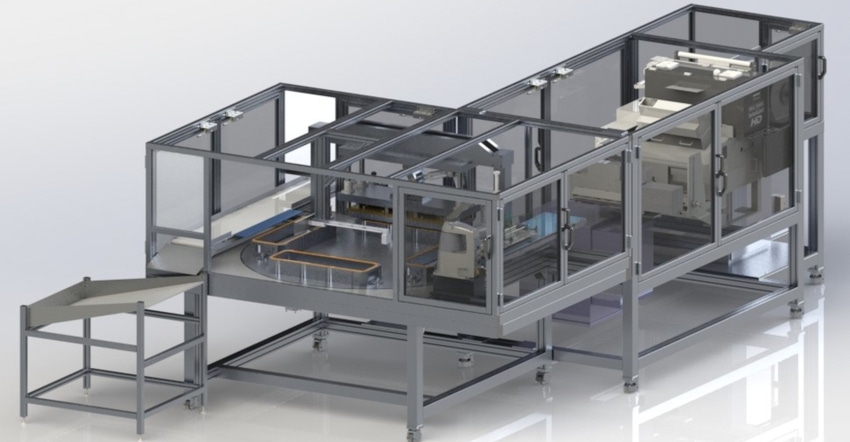

A medical-market first, the new ProMax OnDemand tray sealer prints, places, and seals lids at up to 14 cycles per minute.

Medical device customers often make do with tray sealers that are designed for food applications. They work, sure. But they’re not optimized for the specific needs of the medical market.

The new automated ProMax OnDemand tray sealer from SelectSeal is.

In this Packaging Possibilities podcast, SelectSeal’s Senior Technical Advisor Jon Ford explains the ins and outs of this new machine. We learn how:

• Sizing the lidding web to the tray width virtually eliminates scrap, for a material savings of about 40%;

• The servo design minimizes the system’s bioburden for Class 100,000 cleanrooms (which is Class 8, not 7 as identified in the podcast);

• Cutting doesn’t place undue pressure on the seal because the lidstock is cut just prior to placement and sealing;

• A loadcell — a transducer that converts force into measurable electrical output — ensures accurate measurement of seal quality;

• Changeover can be accomplished in minutes with a simple swap out of the bottom tooling only, and SelectSeal uses RFID codes on the tools that match a recipe so the user can never run the wrong tool.

PACKAGING POSSIBILITIES - Season 2: Episode 13

If you have a topic you’d like to propose for a future PACKAGING POSSIBILITIES episode, please email Lisa Pierce at [email protected].

TRANSCRIPTION IS AUTO GENERATED

Lisa McTigue Pierce

Hello! This is Lisa Pierce, Executive Editor of Packaging Digest, with another episode of Packaging Possibilities, a podcast that reveals what’s new and what’s next for packaging executives and engineers, designers and developers.

In this episode, I’m talking with Jon Ford from SelectSeal Packaging Machinery, where he provides sales and technical assistance.

We’re going to learn more about the company’s new machine, which is a first in the medical market.

So I understand that the machine that we’re talking about, the ProMax On-Demand system, is a tray sealer specifically for the medical industry, correct?

Jon Ford (guest)

Correct.

Lisa McTigue Pierce

So one of the unique advantages of this system is that it does on demand printing and cutting of the lidstock. And you say that this is a first in the industry. Is that what the first is — is that it’s both on-demand printing and cutting of lidstock?

Jon Ford (guest)

Yeah, pretty much, Lisa. To kind of explain it, to put it in perspective … is most of the tray sealers of this type out there today are for food product. And typically, they’ll take a pre-printed material and they’ll run it through and seal it to a tray and then cut it out as a seal. So they’ll actually cut the film out as they seal it. And it’ll exit the machine and these … The problem with these machines is they’re not used to 45 mil, 50 mil PETG trays and they’re not used to Tyvek.

Lisa McTigue Pierce

OK.

Jon Ford (guest)

So the whole sealing process was developed for food. Everybody out there trying to run medical trays on it are having a difficult time with alignments in the sealing parameters and trying to cut Tyvek with a serrated knife instead of a die punch. So, with that said, we had developed a rotary sealing machine that we’ve sold numerous of historically, so we know that technology is 100% proven and validatable.

The whole sealing process was developed for food. Everybody out there trying to run medical trays on it are having a difficult time with alignments in the sealing parameters and trying to cut Tyvek with a serrated knife instead of a die punch.

Lisa McTigue Pierce

OK.

Jon Ford (guest)

To that, we wanted to add … now how do we automate the system of putting a top sheet on the tray. Cause typically today they’re hand loaded. You hand load the tray, you put it with your device, you put your top sheet on, and you run it through the system. That’s how the medical one’s work. So what we’ve done is we’ve taken a rollstock of Tyvek, unprinted, and we size it to the exact width of the tray, so there’s no side trim. We run it through a Bell-Mark UV printer so we can run one color or eight colors. We print the material and we cut it to length of that tray that we’re currently running and then we pick it with a robot. We align it with a camera system, we pick it with the robot, and place it in the machine.

So we literally have no scrap trim. We’ve precut it, so there’s no stress on the seals while we’re trying to cut and it’s placed in the machine. So it’s really on demand in the sense that you don’t have to carry a bunch of lidstocks in stock. Like if you have 20 SKUs [stock-keeping units], you’ve got to have 20 SKUs of cut sheets printed. There’s a good chance of mixing them up. With this system and the camera — there is a pre camera and a cleaning system right after the roll — we verify the print’s correct for that SKU.

Lisa McTigue Pierce

OK. And that’s …

Jon Ford (guest)

So no chance to mix up.

Lisa McTigue Pierce

… and that’s also validatable?

Jon Ford (guest)

Absolutely.

Lisa McTigue Pierce

OK. A couple questions I have for you. Is this new sealer then considered an inline system, where as your others were rotary?

Jon Ford (guest)

It continues to be rotary …

Lisa McTigue Pierce

OK.

Jon Ford (guest)

… once the tray is placed in there. So the tray will be placed in either by human or with the robot. The camera system will check it, that all the components are there and complete. It will verify it back to the printer, so we know that print’s going to match, and through a camera system and through a scanning system. And then it will go into the second position where the lid is placed, and it will go into the third position where it is sealed. In the fourth position, where it’s removed by a robot on door conveyor system.

Lisa McTigue Pierce

OK, excellent. I understand the steps involved and I’ve seen both inline tray sealers, as you already know mostly from the food industry or used in the food industry, and I’ve seen a number of rotary tray sealers, both medical focused, as well as just in general for whatever product.

Jon Ford (guest)

Sure.

Lisa McTigue Pierce

So a couple of questions about the benefits of this. Are you able to … what kind of speeds are we looking at and is an increase in speed one of the benefits of doing it as a printed lidstock rather than pre-printed?

Jon Ford (guest)

Yeah, there’s a … First, there’s a reduction in manpower because the robots are handling the infeed and off-feed. And then, secondly, it’s a … we can probably run a consistent 12 to 14 cycles a minute because, again, a person isn’t trying to place a lid and line it up. All that’s being done automatically. So that’s typical with the Tyvek and a PETG tray, with most of the Fortune 500 medical device guys. They like to see 3 to 3 1/2 seconds of seal time. So that’s really the limitation.

There’s a reduction in manpower because the robots are handling the infeed and off-feed.

We, you know, we have to have that seal time. We can do everything else, in that period of time, in about 2 seconds.

Lisa McTigue Pierce

OK, in two seconds, instead of three and a half?

Jon Ford (guest)

Yeah, yeah.

Lisa McTigue Pierce

OK. How were you able to increase the sealing speed?

Jon Ford (guest)

No, I’m sorry. I apologize for that. It still takes it … I’m saying if we didn’t have the three second cycle time required by the Fortune 500 medical device guys, we could run this process in two seconds. Tyvek, at 280 degrees, with a 1074B Tyvek, which is a better Tyvek … we can typically seal it in a second and a half and get perfect peel strength and the excellent quality seal in our sealer.

Lisa McTigue Pierce

Ah. Umm.

Jon Ford (guest)

It, again, I think it’s a legacy of 3 seconds. It’s just like I’m sure you’ve heard all the peel strength talk about what, you know, one pound versus two pounds versus … there is no standard.

Lisa McTigue Pierce

Right. It’s all over the place as long as you’re able to maintain the sterility, if it is a sterilizable package, product inside as well, yes.

OK. Is the lidstock, as it’s printed online, is that less expensive than the pre-cut, pre-printed lids? And I understand the improvements from an inventory point of view, inventory management point of view. But what about just cost in general?

Jon Ford (guest)

Sure. It’s considerable. They give me a percentage, but as you know Tyvek’s price has been changed almost daily, monthly and, depending on whether you’re running 1074 or some of the new Tyveks out there, it’s varies greatly. But the savings is about 40% in actual cost savings of printing online versus buying a preprinted sheets.

The savings is about 40% in actual cost savings of printing online versus buying a preprinted sheets.

Lisa McTigue Pierce

That’s quite substantial.

Jon Ford (guest)

Yeah. I can’t give you the dollar amount or the penny amount for … because the price just … I’d say something today and it could change tomorrow.

Lisa McTigue Pierce

Sure. Well, not only that, but I’m sure it’s dependent on the product that’s inside as far as how much information you need. For example, a single product versus a kit …

Jon Ford (guest)

Sure.

Lisa McTigue Pierce

… obviously is gonna have more things there.

Jon Ford (guest)

On a, for instance, on a 28-inch long tray that’s 8 inches wide, the scrap savings alone over conventional tray sealer’s 25%. So that’s a huge number. So if you’re, you know, if you’re 224 square inches of Tyvek and you don’t have any side trim, which is 56 square inches, that’s a big number.

Lisa McTigue Pierce

How do you get away from not having the side trim? I would imagine that this sealer has the flexibility of handling a variety of different tray styles.

Jon Ford (guest)

Correct.

Lisa McTigue Pierce

So is that just a way of managing the order of the rollstock?

Jon Ford (guest)

Yes. So what we’re doing is, for instance, the one, the current one that’s in production has five different web with trays. So you do have five SKUs of Tyvek. But you know it’s unprinted Tyvek; the roll can sit there forever. So you’ve got five SKUs instead of … we’re running 28 different trays, five different widths. So you have the savings of 23 SKUs in material.

And also that doesn’t have to be preprinted cause you still have to, you still have to print, so when you do a lid for a trocar or an endoscopic tray, typically the print can be there, but then you have to come back and print your expiration date and your lot code on it. So you still have to take that lid and stick it in a printer manually and print it. So we’re printing the whole thing. We scan in a worksheet or route sheet from the customer and that will tell you how many trays we’re going to run and what the date, code date is. That information’s fed to the camera. So there’s a complete check all the way through the process.

Lisa McTigue Pierce

OK. And are you able to maybe give any details on the inspection technology that you’re using in the machine?

Jon Ford (guest)

Yeah, we’re using … again, that’s kind of customer specific. In this case, we’re using a Cognex system. The software is our own. It’s a proprietary software we use. We’ve used it for a number of years to be able to look at the, to be able to scan in and follow the process through the machine. So it’s constantly being checked as it goes through the machine.

Lisa McTigue Pierce

OK, excellent. I need to get a better handle on the no scrap.

Jon Ford (guest)

Oh, OK.

Lisa McTigue Pierce

So I understand that you’re sizing the width and then you say you’re able to do the cutting. Is that prior to the lidstock being positioned on the tray?

Jon Ford (guest)

Yeah, correct. So one of the benefits we have is our parent company is Ontario Dye Co. And for 100 years, they’ve built punch dies for thermoforming equipment. And I was a customer of theirs for a number of years. So they are building the cutting system for it. So in some cases, some of the SKUs use square corners because it’s Tyvek, and the PETGs already got round corners. In other cases, they want to be a different peel tab corner, so we need to do a round corner.

So we have a ... So it comes off a roll through a dancer system. Then it goes through the printer. When it comes out the printer, it goes through a series of static clean web cleaners, where it cleans any debris created and then we have an ODC die that has changed-out cartridges. So it’s the … it’s about a 5-minute changeover to change the cartridge width.

If we’re running all square corners, you don’t have to change because it’s just this, you know, steel roll knife going across. So there is … when I say it didn’t say exactly scrapless … there’s probably 1/4-inch strip that’s taken out because we use a dog bone to punch the Tyvek.

Lisa McTigue Pierce

OK. Dog bone. I’m not familiar with that.

Jon Ford (guest)

Dog bone is a male/female die and it’s literally shaped like a dog bone. It gives you the round corners. So in the end it’s got some round corners and they … it’s just a term that they’ve used for years.

Lisa McTigue Pierce

OK, excellent. First time I’ve heard it. Awesome. Thank you for that. That’s a lot of fun. I like the insider information on that. OK. And so the product loading could be manual or robotic?

Jon Ford (guest)

Correct.

Lisa McTigue Pierce

OK.

Jon Ford (guest)

Yeah, and the reason for some of that is a lot of times they will have, prior to our machine, they’ll have a cleaning station where they literally clean the instrument, they blow out the blister, make sure everything’s out of there. So you may have a very simple blister that you have a catheterization tool in there, and that’s it. There’s no other parts to it. There’s no tubing or anything, which is very easy to load in the machine and check. In other cases, we might have three or four components in there with a, with scissors or a kit, as you’ve seen before, there might be tubing and, in that case, typically they’ll load that product manually, and you’ll have to actually lift it in because a lot of times there’s a retainer that goes on there before the Tyvek.

So how you present it depends on really how simple the instrument is. The one we’re doing right now, they want to hand load it because they want a final check of the tray and the components even before the camera looks at it.

Lisa McTigue Pierce

OK, so that’s a human visual inspection, which is always helpful. Always helpful. OK.

Jon Ford (guest)

That’s correct.

Lisa McTigue Pierce

So then the position of the lid, which has been printed and cut, the length cut in advance, is that also either manual or robotic?

Jon Ford (guest)

No. Yeah, that goes on to a conveyor and that’s where we have a camera system that’s looking at the four corners of it and it’s adjusting the robot in all directions. So when we pick the sheet, we will adjust that robot to where the tray’s going to set in the machine so that the top web will be loaded into the machine automatically.

Lisa McTigue Pierce

OK. So it’s mechanically positioned.

Jon Ford (guest)

Yes. And inside the tooling of the machine, there are pins. So we will actually drop it down, drop the Tyvek down into a series of pins that holds it in place as it rotates.

Lisa McTigue Pierce

Is the flange of medical trays usually a little bit wider than say a food tray?

Jon Ford (guest)

Yeah, typically the the spec is .49, so it’s almost a half an inch and it’s usually, you know, plus or minus .01. So yeah, they’re quite a bit wider.

So we’ve got, we’ve really got it down to the science on our sealers because we’ve run so many of them on how many pounds per square inch it takes to seal 1074 Tyvek to PETG, regardless of, you know … they’ve got different sealants they’ve come out with here lately. Amcor and some of the other companies. And we really hadn’t had to adjust that pressure at all. Again, most of the Fortune 500 run almost twice as much pressure than actually required.

Lisa McTigue Pierce

OK, excellent. I’m assuming that the seal is still a heat seal. Are you investigating ultrasonic at all? Is ultrasonic even anywhere appropriate for this type of application?

Jon Ford (guest)

No, not for a peel seal. A peel seal, you know, the adhesive is a critical step. Again, when we validate what, or when we FAT [Factory Acceptance Test] the machines before they leave with our customers, we will run and seal 500 trays. And from that, we will take six spots on each tray and do a peel test.

And then we’ll do bell curves to show what that peel looks like. And you’ll be amazed at how tight that peel is. So if we set it and we’re running a pound and a half, it will, it will go from 1.3 to 1.6. We can really hit that target. We’re using a servo system for the sealing and we’re controlling it with a Proportion Air system and a load cell.

So we’re monitoring the whole system for the load cells. So our load cell doesn’t start our timer until we hit our 225 pounds.

Lisa McTigue Pierce

OK, I am familiar with load cells, but more from the point of view of, say, a food operation. Typically working with a combination scale into a vertical form-fill-seal. Could you explain a little bit more about the load cell so I understand the benefit of this here?

Jon Ford (guest)

And why we use it is … in the older machines with air pressures we could take … we always use cylinders. We never use bladders in our seal head. And the reason we did that is we can measure the diameter and the stroke of a cylinder and we … if we apply 50 pounds to that cylinder, we knew exactly how much it’ll generate. With a bladder, you can’t do that because you don’t know how much you really blown that bladder up. So, therefore, in medical we always use cylinders. To double check that number and make sure we’re right, we’ll put a load cell underneath the tooling to make sure that pressure matches. And that’s our QC point, because if we’re setting it at 225 pounds, we hit 210 pounds, it’s rejected.

So we’re constantly looking at that. It’s our system of validating what the machine is actually doing. Because when you go to servo, if you’re just looking off the information from the servo, that’s electronic signal. That’s not always your best way to do it. You really want a more a precise method like a load cell instead of a servo-generated number.

You really want a more a precise method like a load cell instead of a servo-generated number.

Lisa McTigue Pierce

OK. And I believe that’s also required … it’s been a while, Jon, since I’ve been up on the regulations, but I believe that double check from a validation point of view is required by 21 CFR part 11, correct?

Jon Ford (guest)

Sure, that’s correct.

Lisa McTigue Pierce

OK, we’ve come a long way since you know the good old days when nothing was digital and nothing was electronic.

Jon Ford (guest)

Yeah. Yeah.

Lisa McTigue Pierce

Amazing.

Jon Ford (guest)

And I think by going to the[PACK]out, we learned why a lot of this stuff is important for the sterility of a of a package.

Lisa McTigue Pierce

Could you tell me a little bit about what the smart tool change is all about?

Jon Ford (guest)

Yeah. So again, if you, I don’t know if you’ve ever seen a tool change on a food machine.

Lisa McTigue Pierce

For thermoforming?

Jon Ford (guest)

No. For a tray sealer.

Lisa McTigue Pierce

OK.

Jon Ford (guest)

OK, so the entire … first of all, the bottom tool comes out, which is pretty normal cause it has to change with each size and it usually comes out on a rack. The problem is the upper tool, you gotta remove the entire seal head. So you’re moving the seal head. You’re taking all the heaters out. You’re taking the knife system out, perimeter knife system. And typically a change out on that for 20-22 inch tray is around $55,000 to $75,000 for the components. And it’s probably a good half hour, even with all the automation they’ve got today of racks and pulling it out. You’ve gotta drop the heat. You gotta unplug the heaters. You gotta unplug the air. You’ve gotta be careful with the knife hanging in there because it’s a serrated knife. It’s a very sharp knife.

Lisa McTigue Pierce

Is that 30 minutes just for the top or is that total?

Jon Ford (guest)

Yeah, I can say … I would say so. You know, I hate to say that because there’s all different. You know, there’s five or six … 10 manufacturers, this type of system. Some have done a much better job than others. And those that aren’t, are certainly improving because that’s a big deal. But again, most food tray sealers will run the same product over and over. They don’t … It’s not … they’re not changing it like the medical, will not change this thing three times in one day.

So what we’ve done over the years and, again, this is through working with a customer and testing. We happen to have one of our sealers at one of the major medical device customers and their test labs. So we get a lot of good feedback.

We use a flat seal plate on top and then we … that’s our only change out are the four lower tools. And those tools are about 10 or about $8,000 for set of four. And then what we do is we get specially made gaskets for sealing on the bottom. We raise those … we make them thick and we run them. I won’t tell you the durometer. We run a very specific durometer on the bottom.

Lisa McTigue Pierce

What does durometer mean?

Jon Ford (guest)

It’s the hardness of the rubber of the gasket. That’s very critical in sealing Tyvek. And by controlling them, by controlling that, we’re able to use one flat seal plate and not getting any bleed through because of our gasket design. So we get a perfectly sealed with no bleed-through with a flat plate. So there’s no upper change at all. Nothing to do. You just pull out the tool, they’re on pins, they’re not bolted down, you just pull them out and reload four more for the next product.

Lisa McTigue Pierce

That’s genius. Genius. Do you have a video of the changeover by any chance? Or the operation of the machine?

Jon Ford (guest)

Not yet, no. This is the first. This is the first one we’re building. This is the very first machine we’re building. And it came … again, it came about because the problems with trying to use a food … you know, the biggest problem with the food machine is your sealing hot Tyvek at 270 and 280 degrees for three minutes. Then you’re gonna try to take a serrated knife and cut it on the edge of that hot seal. So you’re literally pulling on it because you’re cutting with a serrated knife, not punching it. And it loosens the seal.

Lisa McTigue Pierce

OK.

Jon Ford (guest)

But Tyvek, if you take a …

Lisa McTigue Pierce

Especially if it’s a peel seal.

Jon Ford (guest)

Yeah, absolutely. If you take a fresh Tyvek tray out of machine and peel it, it’ll pop right off. It won’t even take a half a pound. You have to let it cool. So that’s not the place to cut it using the machine.

If you take a fresh Tyvek tray out of machine and peel it, it’ll pop right off. It won’t even take a half a pound. You have to let it cool. So that’s not the place to cut it using the machine.

Lisa McTigue Pierce

OK. That makes total sense. Total sense. That is a fascinating. I really can’t wait to see that. Are you going to be exhibiting this anywhere anytime soon?

Jon Ford (guest)

Well, we … our original attempt was to take it to Chicago, to the show.

Lisa McTigue Pierce

OK. Pack Expo.

Jon Ford (guest)

Yeah. And our problem is, is we were building two. One for a customer and then another one. And the second one got sold.

Lisa McTigue Pierce

Ah.

Jon Ford (guest)

So we’re behind them right now. So we’ll probably … it probably won’t be till the MDM or Vegas … those two.

Lisa McTigue Pierce

OK, in 2023. OK, excellent. Well, congratulations on that. It sounds like there’s a real need for this in the industry, if the sales are moving that quickly.

Jon Ford (guest)

Believe me, Lisa, I wanted to. I wanted so bad to get one in Chicago. It’s just, you know, the whole business at ODC and tooling and that, like everybody else, they’re just, they’re just jammed with orders, you know, once the COVID kind of released and now the surgeries are taking all surgeries. It’s just, the business going crazy, you know.

Lisa McTigue Pierce

Yes, which is sort of good news, bad news. I hear you. OK, just a couple more questions about that, and just, you know, I’m sure you’re … if you have the opportunity of doing this, I’m sure you’ll do this, but … either one of those machines, before it ships to the customer, if you could do video on that and at least have the video at Pack Expo, that will make all the difference in the world too.

Jon Ford (guest)

Yeah. Yeah, that’s what we’re going to try to do.

Lisa McTigue Pierce

OK, so I understand that this system is also a Class 7 cleanroom compatible. Tell me a little bit more about what that means. And is Class 7, you know, good enough?

Jon Ford (guest)

Yeah. Class 7’s to 100,000. When you go to the next step, it’s 10,000. That’s more for microchips.

[Lisa McTigue Pierce

Just a quick correction: Instead of Class 7, it is Class 8 that is the 100,000 cleanroom designation.]

Jon Ford (guest)

So typically people would be, you know, gowned up, with a hair. The reason we push it is, one of the things I learned a long time ago, and the reasons we’re getting rid of air is … the biggest enemy in a clean room is a bioburden and the bioburden is any air that you put in the machine, you have to take out of the room.

And the same thing with the size of the machine, the floor space. All that adds to the bioburden. So this machine we virtually eliminated all air. Everything runs off servo. We’re gonna have five or six axises servos. There is slight amount of air that has to be used for the printer, but we will exit that from the room. So it was very important to us on all the machines we built that we were able to come in and reduce the footprint and reduce the bioburden that the machine was created in the room.

It was very important to us on all the machines we built that we were able to come in and reduce the footprint and reduce the bioburden that the machine was created in the room.

Lisa McTigue Pierce

How did you?

Jon Ford (guest)

But these rooms are getting they’re getting packed with equipment, cause the clean room is very expensive, as you can imagine.

Lisa McTigue Pierce

Yes, and a system like this, especially if you’re doing manual loading, you don’t really have an opportunity to have this be its own thing ... And I know what that word is ... uh … an aseptic … Yeah, environment. I … they call it something else. I can’t … the word’s not come into my mind right now, but I understand what that is.

Jon Ford (guest)

Yeah, you typically like it Class 7. You typically wouldn’t use … You know you wouldn’t have HEPA filters over the machines and stuff. You have … you cover up the webs, the unwinds and you know you take … you clean the product with static elimination and things like that.

Lisa McTigue Pierce

So there’s a lot that goes into it to make it work in the specific applications that you’ve already mentioned, from a medical point of view. So endoscopic instruments, trocars … which, once you mentioned trocars, I went on the Internet and I’m like, oh, OK, that’s what a trocar is.

Jon Ford (guest)

Yeah, there’s a lot of them. Yeah, a lot of simple instruments. And it could do medical trays. They could do. I mean, you could do HIPS [high-impact polystyrene] trays in it. You know, HIPS right now is kind of like forbidden in some of the facilities. But it can run, you know, anything that’s rigid and can hold up from … you know, there’s some 12-mil materials out there that it could run and it can run … it really wouldn’t care. It could run 100 mil if anybody ever wanted to do it because we’re not punching it out, so …

Lisa McTigue Pierce

Right, right.

Very interesting how the … not only the design of the machine, but the process … that you’ve made sure that it fits for this particular application. Now you mentioned that the two machines that you were working on have already been sold. So you’ve already got customers. Is there anything you can say about either the customer itself or the customer’s application?

And did you learn anything as you were working with these customers to kind of adjust the machine even more?

Jon Ford (guest)

Yeah. What we do … this is what is interesting about this machine. So the current customer has a food machine that they’re … I won’t say it’s running badly, but they’re producing product on it right now, and we’re looking for … And I saw it run. That kind of inspired me to, like, boy, this is not the way to do it, especially when you’re cutting hot Tyvek. So we came back and said, look, we … our mission is to try to get the customers in the Fortune 500 group to actually work with us in partnership on a machine, which is very hard to do because, you know, you get into that we/they thing.

Our mission is to try to get the customers in the Fortune 500 group to actually work with us in partnership on a machine, which is very hard to do because, you know, you get into that we/they thing.

But what I found out over the years — and I’ve been doing this for about 40 years now — is the customers are coming around now because it is our machine. If they’re going to spend $700 [thousand] to a million and a half to buy a machine, it should be what they want. So we were very fortunate to have this … the perfect customer that said … that we asked to take part in the design of this. And we said, look, you’ve got 15 or 20 sealers we’ve done, we know how to seal the product. We know that works.

So let’s go to the print-and-cut end and now we’re with our parent company that’s an expert in cutting. And we’ve worked with several printing companies that are expert in printing and already doing this on … in different facilities. And we came together as a group. Myself and Michelle [Bergeron] are engineers and designed the concept. We literally brought the customer in and together we refined it and came up with a machine that we all feel is going to come out of the box and work 100%.

We literally brought the customer in and together we refined it and came up with a machine that we all feel is going to come out of the box and work 100%.

Lisa McTigue Pierce

OK.

Jon Ford (guest)

So it’s really our, probably our second or third kind of full joint venture where the customer is participating. So that always makes for a better job because we’re all in it, it’s their machine and you know we’re all gonna take responsibility for this process working. So it’s just a really … it’s been a really good relationship.

Lisa McTigue Pierce

Great. And yet you’re able to take the design and maybe sell it to other companies in the medical industry?

Jon Ford (guest)

Yes, yes, we own the design. One thing we do do though is we do share those designs with the customer. Again, we when we look at it is … we’re not in the … we don’t think they’re in the business of building machines. I’m not going to build a medical device. So we need to trust each other and move forward on this. So historically the companies I’ve had, we’ve always given the drawings to the customer. We give them the bill of materials. We’ve even given them our vendors’ part numbers, anything that make it easier to run and maintain that machine.

And I, you know, to this day at least I can go back and I can go up to Norfolk, Nebraska, and see a machine that I built 27 years ago. They totally take care of it themselves. They know it inside and out and it’s exactly how I want it to be.

Lisa McTigue Pierce

OK, that’s win/win then. And that’s what’s gonna help continue the innovation and advancement cycle in the industry. This is a perfect example of how all that works.

Jon Ford (guest)

Yeah, you really get that with medical device. I so wish the food guys would realize that. I mean, we saw a machine that medical, you know, we get a book four inches thick of specifications. And yeah, you have some pain to read. But you know what? It’s what it is. You build a machine to that spec. There’s no argument at the end of the game.

Lisa McTigue Pierce

Excellent.

Jon Ford (guest)

I remember years ago building a hot dog machine, finishing it up, they forgot to tell me the hot dogs are frozen … ’till we got ready for check out, I mean. “You should have known that.” I said, “OK.” So stupid me.

Lisa McTigue Pierce

I don’t know … OK, except for this example, I don’t know of any hot dog manufacturer, producer, who freezes the dogs before they package them. That just seems a little bizarre to me, but OK, obviously there’s one of them do. Yeah.

Jon Ford (guest)

That’s probably why he’s out of business today. He was in Saint Louis.

Lisa McTigue Pierce

OK, John, thank you so very much. This has been very interesting to learn about this new technology and I can’t wait to see it in action, either in a video or in person. So thank you.

Jon Ford (guest)

Yeah. Appreciate that and it was great meeting you.

About the Author(s)

You May Also Like