December 11, 2017

“What we have here is a failure to communicate.” That famous quote from the movie “Cool Hand Luke” applies all too often to Marketing and Manufacturing departments. Don’t get me wrong, Marketing has to be king. If they can’t sell it, there’s no point making it. But sometimes simple changes in a package make it easier to manufacture, which means lower costs and higher profits. So Marketing and Manufacturing must be talking from the first “Wouldn’t it be cool if we could…” moment.

Think little things don’t matter? Simple changes can save millions of dollars over the life of the package. Each 2% efficiency improvement is an extra week of annual production. That can be hundreds of thousands or millions of additional products to sell.

Here are three, real life, examples:

1. Simplify package styles to minimize or eliminate changeovers.

If you bring in Manufacturing early during the package design phase, you may be able to prevent unnecessary costs and headaches.

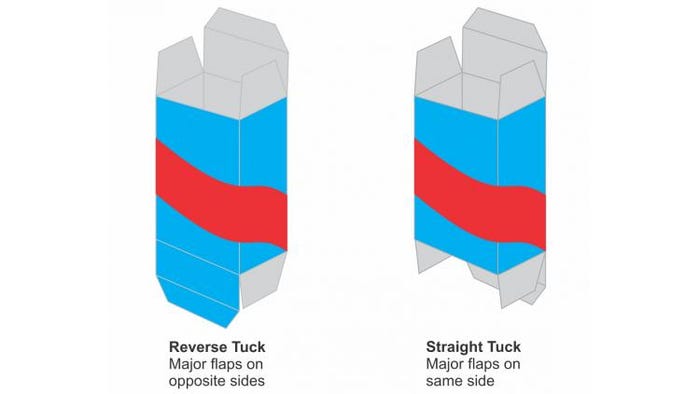

For example, cartoning machines can run reverse tuck or straight tuck cartons but not both on the same machine. One company ran straight tuck cartons and changing over the packaging line between products took about 45 minutes. Then Marketing specified a reverse tuck for a new product. Changing from straight to reverse, or back, takes more than five hours. Marketing agrees that there is no structural or marketing reason for the reverse tuck but, now that it is in production, they are reluctant to change it.

Photo from "Packaging Machinery Handbook," courtesy author John R. Henry.

Manufacturing could have pointed out the problem when it was easy to fix—if there had been communication early on.

2. Standardize sizes to boost efficiency.

Here’s one time when “close enough” definitely doesn’t cut it. Several of this company’s cartons were similar in size. Standardizing size where possible would have added enough additional production time to offset any material costs many times over.

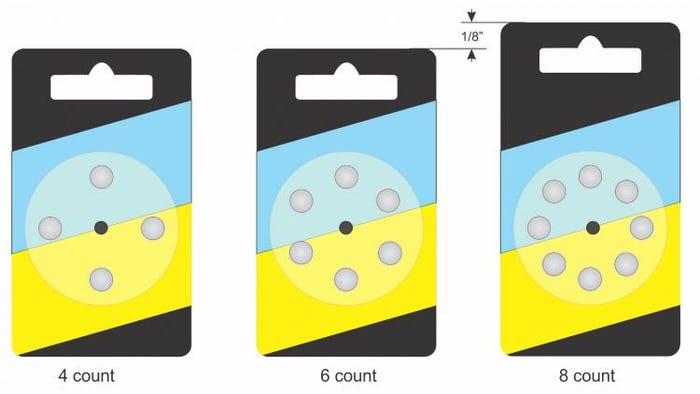

You’ll see this card hanging by the checkout counter. The company made more than 800 stock-keeping units (SKUs) for its own and other brands. About half the cards were 1/8-inch longer than the others. No reason for it, it just happened somehow. Going from ship-from-stock to make-to-order, the company increased market share by 8%. The downside, though, was many more changeovers and the delay caused by two different cards. It cost $400 per card to standardize but standardization allowed the company to go from four shifts down to two.

Photo from "Packaging Machinery Handbook," courtesy author John R. Henry.

Count was another issue. Changing from a 4- to 8-count pack, and back, was easy. Going to 6 and back was time consuming. The plant manager argued for standardizing on just 4 and 8 but Marketing thought there was customer demand for a 6-pack—so it stayed.

3. Eliminate unsightly label skew to create a more attractive package.

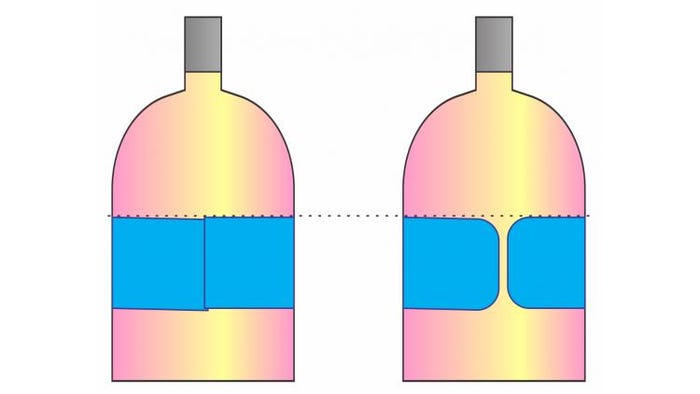

Full-wrap labels on round bottles are sensitive to skewing, where the ends do not align. It may be machine-, label- or bottle-related but all the customer sees is an imperfect product that reflects poorly on your brand and often goes unpurchased. Where the label ends meet, even a skew as small as a 32/100-inch is noticeable and the plant will drive itself nuts trying to eliminate it.

The problem of skew, if not the skew itself, can be eliminated by using slightly less than a full wrap, leaving a gap between label ends. Any little skew becomes invisible to the customer. Adding a radius to label corners is even better.

Photo from "Packaging Machinery Handbook," courtesy author John R. Henry.

Marketing must always have the final decision, but it must be an informed decision. It can only be an informed decision with early input from Manufacturing. Get to know your colleagues so you feel comfortable talking to them, and make communication a regular aspect of your relationship. It will pay off for both sides.

Known as the Changeover Wizard, John R. Henry is the owner of Changeover.com, a consulting firm that helps companies find and fix the causes of inefficiencies in their packaging operations. He has written the book, literally, on packaging machinery (www.packmachbook.com) and is the face and personality behind packaging detective KC Boxbottom, the main character in Adventures in Packaging, a popular blog on packagingdigest.com.

*************************************************************************************

A magic kingdom of packaging solutions: For packaging engineers, executives and designers—WestPack 2018 (Feb. 6-8; Anaheim, CA) delivers leading technologies, free educational presentations, hands-on demonstrations, exceptional networking opportunities and expert-led Innovation Tours. Click here to register now!

You May Also Like