April 9, 2019

A new additive masterbatch that aids the mobility of injection stretch blow-molded (ISBM) polyethylene terephthalate bottles allows manufacturers and brand owners to run conveyor belts and production robots without needing a spray coating. The material helps users maintain PET recyclability and adhere to European PET Bottle Platform guidelines.

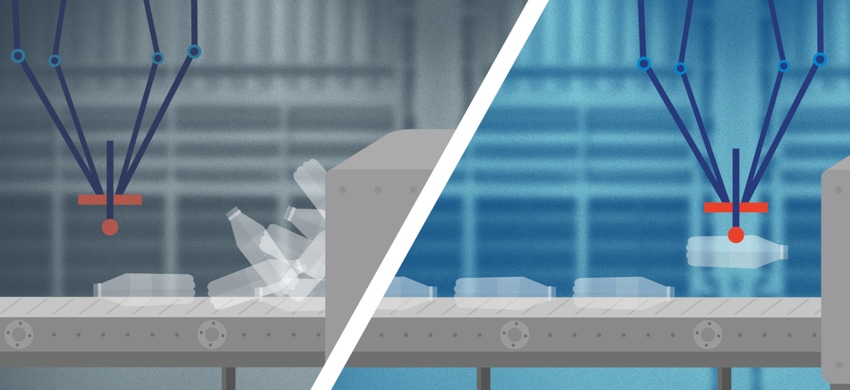

The capability enables operators to run their systems with no interruptions, and minimizes mis-picks by production robots, increasing productivity and yields. From Sukano, the masterbatch avoids problems with release, scuffing and sticking. It reduces cost and cleaning requirements associated with spray coating buildup on machines, and it avoids the risk of microbiological contamination of bottle surfaces that aqueous coatings can cause. For bottle makers, it can be run on existing ISBM bottle equipment with no modifications needed.

The masterbatch produces a silicone-like mobility-aid effect in PET materials while preserving material clarity with minimal impact on haze. It is suitable for use on clear, translucent and colored bottles used in food, beverage, personal care, household and cosmetic applications. It is compliant with the Food and Drug Administration for use in food-contact applications.

Freelance writer and former Packaging Digest senior editor Jenni Spinner is a trade journalist with more than two decades of experience in the field. While she has covered numerous industries (including construction, engineering, building security, food production and public works), packaging remains her favorite.

********************************************************************************

EastPack 2019 (June 11-13) is the region's premier packaging event connecting professionals from companies like PepsiCo, Pepperidge Farms and Mars with suppliers offering the latest packaging technologies, including a range of automation solutions, from semi-automatic equipment to sophisticated "smart" systems. Register to attend today!

About the Author(s)

You May Also Like