June 24, 2014

From robots and ultrasonics to smart motors and flexible packages, the latest packaging technologies on display at the 2013 PACK EXPO show in Las Vegas this fall ranged broad and deep.

With more than 1,600 companies exhibiting, we didn't have time to visit them all. But we did see enough to discern a few trends:

• Machine communication for control, monitoring and diagnostics continues to get easier with smart devices (PCs, phones, tablets) that may also use iconic-based menus to get around language barriers and skill levels. More electronics on machines also means more information is also at your fingertips-for training, for example, or quick diagnostics to minimize downtime.

• Cost savings turned up in a lot of conversations. A number of suppliers were back touting the benefits of their vertical integration (that is providing both machines and materials or raw materials through final packaging), including purchasing simplicity, as well as no finger pointing when problems arise. The importance of this seems to cycle up and down, and it's back on the upswing.

• Regarding production efficiency, the focus is not centered in just one area. If a product was designed for energy savings, for example, it also had a secondary advantage, such as safety, or more. Value is maximized when the same feature provides multiple benefits.

• Sustainability was addressed in a variety of ways, including energy-efficient components in production and a focus on flexible packaging formats.

• With safety top of mind for in-plant and products, especially for foods, we saw a preponderance of new safety devices, as well as inspection systems (many of them using machine vision) integrated into packaging machines. Inspection not only ensures quality product but helps cut down on waste for cost savings and sustainability benefit.

Many of these trends are evident in these products that were introduced at the show:

Pro Mach meets strong demand with new Flexible Packaging Group

Flexible packaging formats in the U.S. have been on the rise in recent years. Packaging machinery conglomerate Pro Mach (www.promachinc.com) has enhanced its capabilities in this area by forming a new Flexible Packaging Group (www.promachflexible.com).

The group consists of existing "Powered by Pro Mach" companies Matrix (vertical form/fill/seal) and Rennco (vertical bagging equipment), along with new offerings as the exclusive distributor in North America from Toyo Jidoki (pouch packaging systems) and Inever (stickpack and sachet packaging machines).

Toyo Jidoki (TYJ), based in Tokyo, Japan, manufactures automated pouch packaging machines for food, retail and industrial applications, and specializes in retortable pouches and solutions requiring fitment dispensing systems with high-quality seals and precise filling accuracy. See a short video of the TYJ filler/sealer in action at PACK EXPO at www.packagingdigest.com/TYJvideo.

Inever, based in Barcelona, Spain, makes stick pack, sachet and 4-sided seal machinery for liquid and powder applications and offers a range of solutions from 2-lane to 20-lane ultra-high speed filling systems.

Barry Heiser, president of Pro Mach's Flexible Packaging Group tells Packaging Digest that Inever's web handling is the best he has seen in 20 years. It is one of the reasons Inever is able to produce foodservice condiment packets that are printed in register on both the front and the back.

- Lisa McTigue Pierce, executive editor

Bosch Rexroth

Compact safety solution designed for use on small and mid-size machines

Scalable safety is made easy to implement in small to mid-range machines using SafeLogic from Bosch Rexroth (www.boschrexroth-us.com). The control expands as the number of peripherals increases. Defined functional modules and graphic wiring simplify configuration and speed up the commissioning process.

Up to four safety controls may be networked via the Enhanced Function Interface (EFI). Each control may operate a different functional area of the machine, and cells may be taken offline independently for maintenance or, in the case of unneeded processes, while operation and safety functionality is retained in the rest of the network.

The SafeLogic Designer graphical tool allows the user to configure, parameterize, program, commission and run diagnostics on the SafeLogic compact. Drag-and-drop features, libraries and the ability to add user-specific functions make this tool so appealing. A simulation mode allows offline verification of programs, while reporting functions make it simple to verify and document.

- Kari Embree, senior digital content editor

Rinco

Compact ultrasonic pouch sealers go right to the topRinco Ultrasonics (www.rinco-usa.com) expands its line of FPA series ultrasonic pouch sealing systems for flexible packaging used for dry and liquid foods, personal care items and electronics. The new FPA 4500-T model offers numerous improvements over its predecessor, the FPA 4500, and gives OEMs the most robust ultrasonic solution with the widest processing window vs competitive ultrasonic sealing and heat sealing processes.

The FPA 4500-T is a high-force, high-speed unit for top-seal bonding of pouches up to 155 mm wide. The new model boasts many upgrades including a single access panel for serviceability and a state-of-the-art washdown resistant coating. The FPA 4500-T has an IP67 rating and meets food contact regulations.

Depending upon the film used, Rinco has determined that its patented interlocking seal pattern can provide a 20 percent stronger bond than conventional ultrasonic seals. - Embree

Bagger now does stand-up, affordably

Automated Packaging (www.autobag.com) showed new capability for filling stand-up pouches (SUP) cost effectively at speeds up to 900 inches per minute on its already proven FAS SPrint Revolution bagger. Polyethylene/polypropylene laminated pouches can be surface- or reverse-printed and are supplied fan-folded, side to side. A mechanical device separates the bags, opens them and positions them for hand loading by up to three operators, suitable for careful handling of delicate products or for low volumes/short runs. Or it can be set up with two automatic infeeds.

The small-footprint bagger can changeover between different pouch sizes and formats (SUP and others) in less than five minutes. At a cost of less than $100,000, estimated return on investment is about 200,000 bags. Sanitary design and 3/8-inch food-grade steel make this system suitable for a variety of applications, including frozen foods. - Pierce

Schneider

ProAdjust provides automatic changeover points for most machinesProAdjust from Schneider Packaging Equipment Co. Inc. (www.ProAdjust.net) is an add-on solution that automatically adjusts the changeover points of most machines to make changeovers fast, accurate and repeatable-which can dramatically improve a machine's overall equipment effectiveness (OEE) and lower costs.

It is a self-contained system consisting of a controller and integrated PowerPacks. The system is scalable from one to hundreds of adjustment points. Wiring is plug-and-go and, most importantly, no programming is required. ProAdjust uses a simple point-and-click touchscreen interface for one-time machine setup and easy "recipe" creation.

ProAdjust can be added onto new equipment as a low-cost option or onto older equipment as a field retrofit. It is compatible with most machinery in every industry, including fillers, cartoners, case packers or palletizers.

- Rick Lingle, technical editor

Robotic arms have soft touch

Universal Robots USA Inc. (www.universal-robots.com) showed how robot arms use advanced force control to handle even the most fragile items.

Ed Mullen, national sales manager with Universal Robots, explains how the force control feature is unique for this type of collaborative robot:

"Though the robot is simple to operate and deploy, it comes with advanced features that allow the end user to automate manual tasks previously not possible due to the exact amount of force exertion needed in the application," says Mullen. "This makes the UR robots an optimal choice for companies looking for packaging and palletizing solutions for items that require specific handling."

Various types and sizes of bottles are handled by the flexible robot that can quickly be reprogrammed for new tasks.

Force-sensing technology enables the robot to automatically stop if it comes into contact with an employee. Of almost 2,000 Universal Robots sold worldwide, 80 percent of these operate with no safety guard. - Embree

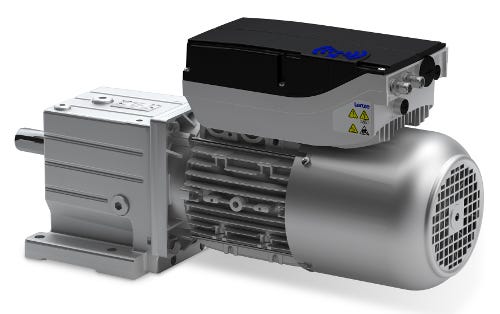

Motor has high starting torque for right sizing, energy savings

Lenze

Packaging operations often oversize their motors to get the higher start-up torque needed to initially power machinery, such as conveyors. The Smart Motor from Lenze (www.lenze.com) has four times the starting torque vs others that offer 2.5 times as standard, allowing operations to use motors that are about two sizes smaller physically and, subsequently, use less energy. Additionally, the Smart Motor can be controlled and monitored by an NFC-capable smartphone for easy setup and operation. See a short video demonstration at www.packagingdigest.com/LenzeNFC. - PierceGhost ‘watermark' provides counterfeiting protection for flex packs

To offer medical device and pharmaceutical manufacturers anti-counterfeiting protection, Rollprint Packaging Products Inc. (www.rollprint.com) introduced new technology at PACK EXPO that integrates overt watermarks into composite flexible packaging materials. Suitable for chevron pouches and more, Ghost can feature corporate logos, brand names or symbology that allow visual confirmation of product authenticity.

Ghost can be applied during the course of film manufacturing with no post-processing and does not add any thickness to the film or weaken it in any way, says Dwane Hahn, vp of sales and marketing, Rollprint. Watermarks are not affected by sterilization nor do they have any effect upon heat-sealed areas. Because specialized equipment is needed to produce the watermarks, would-be counterfeiters would struggle to duplicate them.

Ghost is currently being commercialized for transparent films, but it could be used with the same effect on foil laminations and many other opaque materials. The technology could also be used in conjunction with blister packs, packets, flow wrapping, tray lidding or other formats.

Hahn sees advantages to using Ghost over other anti-counterfeiting approaches: "Companies that are currently using anti-counterfeiting measures typically employ covert options that add significant cost and frequently require specialized equipment. Because the watermark is added concurrently during normal processing, we can usually add the feature at little or no additional cost."

In addition, users do not need any additional equipment or capabilities to authenticate products with Ghost, Hahn told PMP News.

- Daphne Allen, executive editor, Pharmaceutical & Medical Packaging News

Ultra-high-speed inkjet prints more info at high quality

In the past, packaging lines had to choose between higher speeds or more information for their inkjet coding operations-or sacrifice print quality. No more. The new 1620 and 1650 Ultra High Speed (UHS) inkjet coders from Videojet Technologies (http://uhs.videojet.com) incorporate various technologies to deliver legible codes at up to 40 percent faster than the prior industry benchmark: the Videojet Excel UHS. The 1650, for example, has a single-line maximum speed of 1,666 ft per minute.

The UHS printers combine the company's Dynamic Calibration technology, which applies sophisticated measurements and controls to adjust jetting parameters automatically, and the Precision Ink Drop system, which uses leading printhead design with updated software and custom inks to deliver this performance for high-speed operations such as beverage or dairy packaging lines. Uptime is built in: The patented CleanFlow printhead design minimizes planned downtime due to long intervals-up to 14,000 hours-between planned routine maintenance cycles. - Pierce

Sprayer ‘bottle' stands for shelf impact

Mondi

Sprayer Pouch, a new flexible bottle from Mondi Americas (www.mondigroup.com), features a flat bottom for exceptional shelf presentation, has excellent stiffness and offers reduced packaging weight compared with conventional bottles. The patent-pending pouch uses less petroleum-based materials, consumes less energy in production and produces less waste than conventional blow-molded bottles.The Sprayer Pouch is available in various laminate structures, ranging from a PET/PE laminate to foil-based multiple ply laminate structures. The package's lightweight construction can help cut shipping and storage costs. For example, one truckload of empty blow-molded bottles can be replaced by one pallet of Sprayer Pouches. The Sprayer Pouch is recommended for pet care, household cleaners and detergents and garden and industrial products. - Lingle

Intelligent components simplify operations, speed changeovers

Festo Corp. (www.festo.com/us) showed a number of new intelligent machinery components touting machine safety, energy efficiencies and/or flexibility for fast changeovers. For example, new electrical cylinder drives combine motor, actuator and controller in one for lower cost and easier programming. And compact integrated servo motors house motor and drive in one to reduce wiring and simplify operation. - Pierce

Shipper converts to retail display

Delkor

The patent-pending Cabrio Case from Delkor Systems (www.delkorsystems.com) is based on a conventional flange-seal case (FSC) that's formed with angled flaps that create a display open at the front with a higher wall at the back. When opened, the top-loaded case is tilted forward to display product. The rear wall provides support for products in flexible packaging.Precuts on the front and sides of the cases allow easy tear-away of the case top, providing clean lines that enhance the display. Meanwhile, a tear strip is used on the back of the case, away from the customers' view. Sizes can be varied to match product dimensions or rows of product loaded into a case.

Using an FSC case also may result in corrugated savings of between 10 to 20 percent vs a regular-slotted container or 34 to 53 percent vs tray/hood cases. In addition, RSCs must be preglued where the seams overlap, adding an additional machine step that increases costs. - Lingle

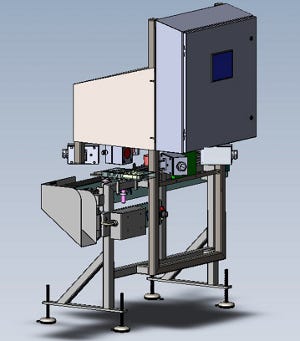

Teledyne

Inspection system upgrades to meet future needs

The SelectVu vision sensor from Teledyne TapTone (www.TapTone.com) is designed to perform visual inspection using a single camera and lighting in a stainless-steel enclosure.

However, up to four SelectVu sensors can be linked to a single user interface to create a modular and flexible vision inspection solution that can change to meet future production line demands.

The system, which can go over existing conveyors and has simple height adjustment, offers a small footprint, tool-less changeover and easy operation via NEMA 4X color touchscreen with icon-driven menus.

Applications include inspection of labels, closures, tamper bands and verification of bar codes and date and lot codes; it can also check the visual fill level of clear containers. - Lingle

Hot melt uses less material, cuts costs

HB Fuller

With increasing demand to bond a range of substrates and with an eye towards reducing packaging costs, H.B. Fuller Co. (www.hbfuller.com) has developed Advantra Encore 4000 adhesive for case and carton sealing.The newest metallocene-based hot-melt adhesive in the Advantra line; Advantra Encore 4000 uses 20 to 30 percent less adhesive than other metallocene-based packaging and uses 40 to 50 percent less adhesive than ethylene-vinyl acetate (EVA) products.

From deep freeze to hot fill, Advantra Encore 4000 performs across temperatures ranging from -40 to 160 deg F (-40 to 71 deg C). It bonds well on a range of substrates, including coated stocks and high recycled-content board. This level of performance offers the potential to switch to lower-cost boards that might otherwise be challenging to seal. - Pierce

ONLINE EXCLUSIVES from Kliklok-Woodman, Placon, QuickLabel Systems, Bosch Packaging Technology, Columbia Machine, Microscan and Eriez:

Servo bagmaker supports weighers/fillers

Introduced at PACK EXPO, the Apache CM continuous-motion bagmaker from Kliklok-Woodman (www.kliklokwoodman.com) brings a new level of speed, operator ease of use and package size flexibility to applications such as cereals, crackers and cookies, candy, nuts and powders.

The new machine uses Allen-Bradley machine control components from Rockwell Automation (www.rockwellautomation.com) in a full servo design for increased reliability and lower total cost of ownership. The Apache CM is built on a cost-saving "Flex-Mount" welded tubular steel frame. This center-balanced frame is designed to bear the weight of weighers, augers and volumetric fillers, eliminating the need for independent support structures and mezzanines. This provides a low overall machine height provides greater installation flexibility.

It offers speeds of up to 160 bags perm minute and is also available with ultrasonic sealing.

Standard features include patented servo motor-controlled Hypocycloidal end seal jaws; self-aligning continuous-motion rotary seam seal bar; swing-away hinged electrical enclosure; powered film unwind and open-design tubular steel Flex-Mount frame; and performance reporting, diagnostics and troubleshooting.

- Rick Lingle, technical editor

Leading supplier talks thermoforming trends for foods

Placon (www.placon.com), a manufacturer of thermoformed plastic packaging, has plenty on the horizon, including at least three complete new product lines in 2014.

While the company was mum on what the new products will entail, Melissa Jacobson, marketing and communications manager at Placon, hints that the communication of recyclability will be a focus. There are numerous complexities in the PET thermoform recycling process and there are still some municipalities that do not accept the material. Those are just some of the recycling barriers the company hopes to help overcome.

"Many consumers do not know that they can recycle thermoform containers," she says. "We really want to help the consumer understand how to recycle and help increase the recycling rate. We're working on figuring out different ways to communicate that with the consumer and that is some things we are trying next year."

Recycling is a focus for the company. After all, it operates EcoStar Plastics (www.ecostarplastics.com), a recycler and manufacturer of post-consumer recycled PET bottles and thermoforms.

In addition to recycling, Jeffrey Lucash, director sales for Placon, says another trend has been the usage of tamper-evident containers in packaging.

"People want it, processors like it," he says. "I think a key feature is for the grab-and-go category. With tamper-evident, consumers know that the food inside is safe."

This past May, the company launched its new Crystal Seal tamper-evident PET thermoformed food containers that are 100 percent recyclable with a patent-pending feature that helps minimize the potential of food tampering. The containers are available in seven grab-and-go sizes from 8 to 64 oz.

The food containers feature no removable byproducts or tear-away pieces, which the company says not only minimizes potential choking hazards but also eliminates the need for shrink bands or tamper-evident labels.

One key feature is the minimal ribbing found in the container on the sidewalls to provide maximum product visibility, which is a big selling point when it comes to food packaging.

"People want to see the food before they buy it," Lucash says. "This is why it's important our recycled PET has excellent clarity."

- Heather Caliendo, senior editor, PlasticsToday

Short-run label printer goes wide

The new Kiaro! 200 wide-width inkjet color label printer from QuickLabel Systems (www.quicklabel.com) is capable of printing high-quality 1,200 dpi high resolution labels that measure up to 8 inches wide by more than 17 inches long, at speeds of 8 inches per second. This new printer is intended to satisfy the short-run labeling needs of manufacturers of large-size products within the chemical, dietary supplement and food industries, among others.

Eric Pizzuti, general manager, says, "With the invention of our Kiaro! 200 color label printer, we can now serve new manufacturers, whose larger products require wider label widths, and who need to print color labels on demand, in-house."

The Kiaro! 200 automatically detects when cleaning is necessary and performs automatic cleanings without wasting a label. According to the company, the Kiaro! 200 prints on an array of substrates, including gloss paper and polypropylene, yielding durable labels that are ready to use as they exit the label printer.

Operation and set up are easy. The fully-integrated design is user-friendly, allowing operators to quickly load labels and inks and begin printing their labels in-house. The print drivers of the Kiaro! 200 are compatible with all major labeling software including QuickLabel's own included Custom QuickLabel, as well as third-party software such as NiceLabel and Bartender.

- David Vaczek, senior editor, Pharmaceutical & Medical Packaging News

Hygienic bagger has a streamlined design

The SVC 4020 vertical form/fill/seal machine from Bosch Packaging Technology (www.boschpackaging.com) was designed with simplicity, versatility and cleanability in mind, focusing on hygienic design to help manufacturers meet diverse food handling regulations. Subsequent machines in the platform will be available with additional pack styles to handle a variety of free-flowing dry, wet and frozen food products.

The SVC has a streamlined design for clutter-free workspaces, simplifying operations. Its electric cabinet has been incorporated within the machine frame to reduce the number and length of cords and cables. Quick and tool-less format changeovers reduce downtime. The SVC is easy to operate via an intuitive human machine interface (HMI) to reduce training time and improve productivity.

The SVC accepts practically any free-flowing product-from sensitive dry infant powders to nuts, confectionery products, mixed salads, cheese, protein, frozen food and other products. Manufacturers can also choose their desired sealing technology, including poly heat seal, heat seal and ultrasonic.

- Rick Lingle, technical editor

New palletizer leads in safety, flexibility and performance

Columbia Machine's (www.palletizing.com) new high-speed, inline palletizer, the HL7200, operates at speeds of 72 to 120 cases per minute (depending on pattern). The system also touts an industry-leading safety package, ultimate in flexibility and high performance levels.

Safety: Columbia's industry-leading safety package includes Category 3 electrical safety components including dual channel safety interlocks and full height light curtains positioned on the full load discharge and empty pallet infeed. A dual slot automatic hoist pin latching system on the full load hoist and pallet dispenser hoist provide a redundant fail-safe protection system. Fully integrated upper and lower guarding with viewing panels and multiple access doors that incorporate a trapped key door access system provide the safety and function that meets OSHA requirements for Minor Servicing.

Flexibility: Columbia's new programmable laner technology with Columbia's proven soft turn and configurable layer table provides accurate and stable layer forming. And, according to the company, this is the first conventional inline palletizer where the operator can create new patterns or modify existing patterns via the HMI. This combination makes the HL7200 ideal for reliable handling of current and future package types and sizes.

Performance: Many standard features make this palletizer the easiest to operate in the industry, according to the company: Minor Servicing, dropped case detection, Smart Squeeze technology, multi-colored light stack to show machine status at a glance and advanced diagnostics and I/O status screens quickly communicate to the operator the status of the machine.

Ted Yeigh, sales director at Columbia Machine Inc., explains a bit more about the features and their benefits to users in an exclusive interview with Packaging Digest at www.packagingdigest.com/HL7200.

- Lisa McTigue Pierce, executive editor

Intuitive machine vision software simplifies inspection set-up

Microscan (www.microscan.com) showcased its latest identification and inspection solutions for product traceability and quality compliance by demonstrating how its bar code readers and smart cameras can be incorporated into packaging lines and machinery to monitor, track and record critical data on products, labels and secondary packaging.

The product line, which is comprised of the Vision MINI and Vision HAWK smart cameras along with the AutoVISION machine vision software interface, was developed to simplify the setup and deployment of machine vision applications. The intuitive software incorporates high-performance features such as bar code quality verification; decode tools for 1-D and 2-D bar codes; OCR and OCV; automated job changeover; and Microscan Link for one-click connectivity to PLCs and other control systems.

- Kari Embree, senior digital content editor

Metal detector display emulates smartphone functionality

Made for light industry applications, including chemical, food processing, packaging, textiles, pharmaceuticals, plastics and rubber, the Xtreme Metal Detector from Eriez (www.eriez.com) boasts a completely re-designed and user-friendly interface. Highlights include full QWERTY keyboard, robust auto set-up, dedicated reject log and vivid display. "We modeled our interface after today's stylish and advanced smartphones," says John Klinge, product manager-metal detection. "Our field sales engineers and their customers played a vital role in the development of our new Xtreme Metal Detector. They gathered crucial information from their customers about what they want and need in metal detection equipment. We designed the Xtreme Metal Detector to exceed these demands and expectations."

- David Vaczek, senior editor, Pharmaceutical & Medical Packaging News

.

You May Also Like