Optimization

thumbnail

Digital Printing

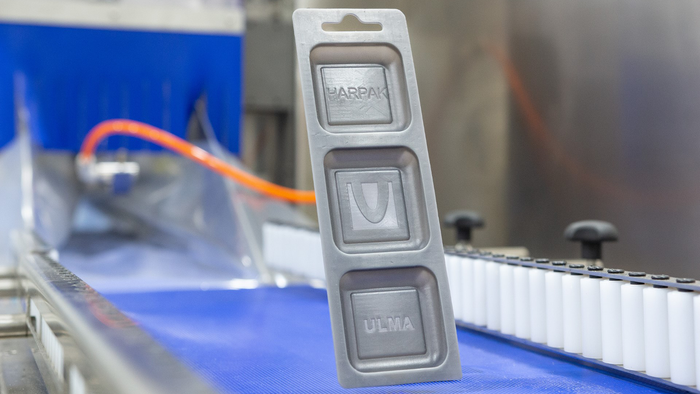

3D Printing Fast-Tracks Plastic Tray Prototyping3D Printing Fast-Tracks Plastic Tray Prototyping

Thermoformer supplier Harpak-ULMA’s nationwide 3D-printing service permits rapid iterative customization of tray dimensions and detailed design features.

Sign up for the Packaging Digest News & Insights newsletter.