February 6, 2020

Cloud, fog, edge: What’s in it for you?

The internet connected people. It allowed them to share all kinds of data in all kinds of ways. The Internet of Things (IoT) allows internet-connected devices to communicate directly. The IoT uses Artificial Intelligence (AI) to make decisions and initiate actions as needed, bypassing people altogether. The Industrial Internet of Things (IIoT) takes it to another level. On a packaging line, the IIoT allows machines to communicate and coordinate with each other faster and better than humanly possible.

The cloud is what makes this happen. The cloud is massive arrays of servers, apps, programs, storage and more in which this communication and decision-making takes place. Because they are massive, they must be centrally located which usually means that they are also remote. Centrality has its advantages but also has a huge disadvantage: speed. Electronic communication may be fast, but it’s not instantaneous. It takes time for data to travel to the cloud and the result to travel back to where it is needed. This travel time, called latency, can be milliseconds and is not a problem in many instances. In other cases, it is.

At 600 bottles per minute, the inspection system has 100 milliseconds to take a picture of a label, analyze it, and make a decision to accept or reject. If it has to send this off to the cloud for processing, even a few milliseconds of latency in transmission will hobble the camera’s effectiveness.

Edge computing moves the processing from the cloud to the edge of the network, putting the processing at the camera. The image is captured, analyzed and the accept/reject decision made locally. The data travels inches instead of thousands of miles. Periodically, the system reports to the cloud how many rejects occurred and why.

Reducing the amount of data, as well as its time sensitivity, reduces load on the network, freeing capacity for other purposes.

The IIoT is all about machines talking to machines. Linking machines through the cloud is impractical due to latency and capacity constraints. What is needed is something in the middle that can connect all machines in a plant. This middle something is fog computing. Fog computing takes place locally, at the plant level. Fog computing monitors the inspection system and, if reject levels are abnormal, sends a text alert to the supervisor. Fog computing monitors the labels used and, when needed dispatches an AMR (Autonomous Mobile Robot) to the warehouse to fetch more.

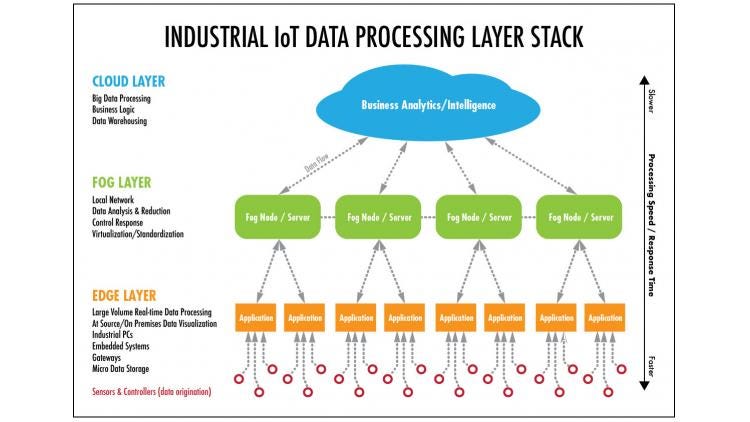

Definitions of cloud, fog and edge can be a bit vague and may vary depending upon the network and operating philosophy. They are best viewed as a continuum, with the edge being hyper local and fast but limited. The cloud has nearly unlimited capability and capacity but is distant and slow. The fog mediates and plays to the strengths of both. This edge-fog-cloud concept is easier to show than explain and this graphic from Winsystems.com lays it out well.

Illustration courtesy of WinSystems.

We hear about the cloud every day but seldom about the edge. Chances are good that you have a number of edge devices on your lines already. The dumb photoeye of yesterday that could only give an on/off signal has morphed into the 3D sensor that not only signals on/off but also position, height, orientation and more. This is possible because of edge computing.

Packaging production operations can now live on the edge. It’s the future. It’s here now. Talk with your packaging machinery manufacturers and device component providers about how edge computing can improve your packaging operation.

____________________________________________________________________________________________

Find your success! Subscribe to free Packaging Digest enewsletters.

Find your success! Subscribe to free Packaging Digest enewsletters.

About the Author(s)

You May Also Like