|

Some companies will go to great lengths to get the most out of their machine controls, even if controls are antiquated, difficult to program and high on maintenance. But, there comes a time when cost efficiencies mandate that new controls be put in place. Upgrading and optimizing the control system on equipment that has been in operation for some time can yield considerable benefits, turning an older piece of equipment into a streamlined asset, increasing speed of production, reducing maintenance and lowering cost of ownership.

This was the case with Blue Bell Creameries, when, in spring 2006, the time had come to upgrade the control systems on its three automated storage and retrieval systems (ASRS) used in its main production facility warehouse in Brenham, TX. Although the 19-year-old breadboard PLCs, old keyboards and 6-in. HMI screens were still functional on the ASRS units, Blue Bell opted to completely upgrade the control systems to improve the equipment's performance, speed and efficiency. The ice cream producer went a step further, however, and installed seamlessly integrated controls system that included wireless Ethernet, PLCs, touch panels and drives from Siemens Energy & Automation, Inc. (www.sea.siemens.com). The controls gave Blue Bell's ASRS the speed and capability to precisely position pallets within the company's main warehouse, even in -18-deg-F temperatures.

125,000-sq-ft warehouse

|

|

Blue Bell considers itself the “Little Creamery in Brenham,” because of its 100-year heritage in a small Texas town, even though the company distributes its products across 17 southern states. In reality, however, Blue Bell is the number-three ice cream brand in the U.S., available in 20 percent of the nation's supermarkets. Although the privately-held company keeps its production volumes close to the vest, it is not shy in saying that it takes approximately 60,000 dairy cows to produce enough milk to meet Blue Bell's ice cream production needs for just one day.

The creamery opened its doors in 1907 as the Brenham Creamery Co., originally to make butter from the excess cream brought in by area farmers. A few years later, the creamery began making ice cream and delivered it to neighbors by horse and wagon. In 1930, the company changed its name to Blue Bell Creameries. Today, Blue Bell no longer produces butter, but it does make about 50 different varieties of ice cream and many frozen snacks.

Its product line includes approximately 20 year-round ice cream flavors, and 25 to 30 “rotational” ice cream flavors that are released throughout the year. It also produces a variety of sherbets, frozen yogurts, low fat/low calorie and no-sugar-added products and a broad line of frozen snacks that come in cups, cones, on sticks and in mini sizes, available in 12- and 24-count cartons.

Blue Bell handles every aspect of its ice cream business in-house, running tight product control from manufacturing through distribution to the retailer's shelf. Finished products are palletized, stretch-wrapped and inventoried into a 125,000-sq-ft cold-storage warehouse with 13,000 pallet locations kept at -18 deg F. Approximately 85,000 sq ft of the warehouse is used for finished products, and approximately 24,000 sq ft is serviced by ASRS units handling 8,000 pallet locations.

Existing units were slow

|

|

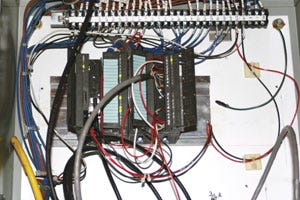

Blue Bell wanted to improve its ASRS accuracy and tracking speed, plus it also wanted to improve its controls operability. The existing controls system, which still used the original PLCs that came with the ASRS units 19 years earlier, was outdated, and a hodgepodge of other PLCs handling different functions on the ASRS units had been added over the years. Although the system was still functioning, it was difficult to work with, time consuming to maintain and would occasionally shut down, causing production delays.

In the old system, an operator would direct the controls to move the crane to a specific X/Y coordinate, where a pallet was located. To arrive at the exact location, the operator would then perform the various motions of loading or unloading the pallets required a multitude of keystrokes. Training an operator was time consuming, because of all of the different combinations of keystrokes that had to be learned. Also, if the wrong keystroke combination was input, when selecting a pallet location, the ASRS would arrive at the wrong location.

Considering that the ASRS had 8,000 pallet locations spread over 24,000 sq ft of floor space to select from, a simple keystroke mistake would add unnecessary time into the production flow.

|

“The original crane systems were using breadboard PLCs,” says Keeter Jenkins, systems designer with Blue Bell. “We were using keyboards and little 6-in. black-and-white monitors. We had difficulty getting into and out of the PLCs, and sometimes they would lock up and require rebooting. Additionally, we were having major problems with our infrared communication units, because the units were obsolete. The infrared units are what we use to communicate with the warehouse database, which tells the operator where to place incoming pallets of ice cream, and where to retrieve pallets to be shipped. So, the decision was made to do a complete controls retrofit before something died on us, and we would need to scramble to get it fixed.”

Controls solution for subzero

The controls upgrade was complicated by the -18 deg F temperature of the warehouse where the ASRS equipment operates. Blue Bell's ASRS are semi-automated, with an operator who rides in a heated cab in the crane. But, outside of that cab, the temperatures are extreme. With massive refrigeration fans on the ceiling creating a cold wind and cold radiating from the concrete walls, the wind-chill factor is far below the -18 deg thermometer reading.

Blue Bell brought in AWC, Inc. (www.awc-corp.com) to help configure a controls package. AWC selected a Siemens controls solution that was fitted to the subfreezing environment and Blue Bell's application needs. “The solution encompasses a Siemens PLC and HMI that are located within the operator cabs and a wireless remote and drives on the subzero cab exterior,” says Brad Rosenhagen, regional director of AWC. Rosenhagen is responsible for managing AWC's Engineering Success Assurance Team for the ASRS controls installation. “The temperature was a concern, but not an insurmountable problem, because we knew we could put small heaters in the crane cabs,” he says.

“Our engineering staff decided on a Siemens SIMATIC® S7-300 modular PLC platform,” continues Rosenhagen. “The unit facilitates an integrated-system solution in both centralized and distributed architectures, and has the ability to integrate powerful central processing units (CPUs) with an industrial Ethernet/PROFINET interface. Siemens SCALANCE® industrial Ethernet network components, which provide rugged connectivity, reliable data communications and comprehensive diagnostics, are also being utilized. This system is particularly adapted to operating in Blue Bell's harsh, subzero environment.” The system is equipped with a Siemens SCD 1297 operator HMI, based on the Windows CE operating system. It has a fully graphics-capable 12-in. liquid crystal display (LCD) with 256 colors and resolution of 320x240 pixels, as well as an integrated serial interface for operation with PROFINET and PROFIBUS. A multimedia card slot enables memory expansions for archives, recipes and backup and restore functions.

Improved operability

|

|

Retrofitting the ASRS controls has achieved significant improvements. It now takes much less time to position and move the crane and manipulate the pallets in and out of the storage racks. Additionally, the new touch screens have reduced the time for each location decision executed by the crane operator by 66 percent, from 15 to 5 sec per decision. Considering the cranes are running daily from 4:30 a.m. to 11:00 p.m., this saves 90 min in command efficiency per crane each day.

Training time on ASRS handling has also been diminished. Because the new system is much more intuitive than the old one, Blue Bell operators can train a new person in one-third the time. An operator can be trained and ready to run the crane on his or her own in just three days, whereas before it would take two weeks of training. The new controls have made these jobs much easier, less stressful, and much more efficient.

The new Siemens controls system not only enables optimized speed and precision with Blue Bell's ASRS positioning, it also provides a seamless integration of wireless Ethernet, PLCs, touch panels and drives connected by a common functionality and control capability. Even the inventory control program now talks directly to the Siemens PLCs through wireless Ethernet. All-in-all, the new Siemens control system has enabled the cranes to take on a new role as highly streamlined production assets for Blue Bell Creameries.

More information is available: |

Siemens Energy & Automation, Inc., 800/964-4114. www.sea.siemens.com. |

AWC, Inc., 800/292-9816. www.awc-corp.com. |

About the Author(s)

You May Also Like