March 11, 2015

|

Recently, the design team at a major consumer packaged goods/food-and-beverage (CPG/F&B) company spent a considerable amount of time optimizing the size and position of the brand logo on the front, top and two side-panels of a club-size box. Meanwhile, in another location, the company's package development team worked on optimizing the strength and cost of the box's handle.

What neither team knew or could foresee was that when the artwork was combined with the final package specification, the resulting carton would have a handle rivet piercing the central element of the brand logo on each side of the box. The product went to market with this flaw undetected, and ultimately led to a redesign that would otherwise have been unnecessary. Money, productivity and some amount of brand equity were sacrificed in the process. No individual or team did their work poorly. The carton was surely beautiful in design, and the handle was certainly up to its challenge.

Derisive diversity

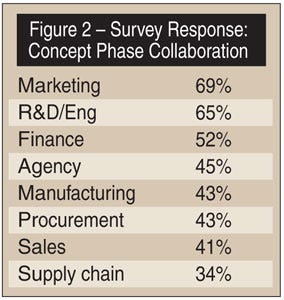

Packaging and artwork management is generally recognized as one of the more challenging aspects of bringing a new product to market. Part of the reason why packaging and artwork management is so challenging is that project team members in nearly every phase of the design process are myriad and diverse (see Figure 1). A study by Siemens PLM Software in conjunction with AMR Research of 128 respondents in the CPG/F&B industry showed that each of eight disciplines listed in the survey questionnaire were named as required collaborators in the process. For example, during the concept phase, every discipline was seen as a key collaborator by a minimum of 34 percent of the respondents (see Figure 2).

An even greater degree of minimum collaboration was seen across the other phases of the process including artwork development, testing and validation and launch. When one considers the degree of collaboration across so many disciplines that's necessary to pull off more than 900 projects/year, which is the all-company survey average, the need for automation and control of packaging and artwork data becomes clear.

|

No place for [inter]play

The IT architecture of most CPG/F&B companies today is built on two pillars:

Enterprise resource planning (ERP) systems that address the needs of the transaction and financial processes of the company; and

Document-centered office productivity suites that provide individual workers with flexible communications tools.

Neither of these pillars provides an effective platform for managing the interplay of communications about consumer and retailer messaging; brand and business requirements; geometry; imagery; instructions; ingredients; claims; and all of the other information that's required in the packaging development process. The consequences of suboptimal IT support for this critical process are errors, write-offs, delays, recalls and brand equity erosion.

Product Life Cycle management (PLM) software addresses information and collaboration challenges by providing a technology platform that manages all brand and package assets in a single, accessible database; facilitates the aligned creation of creative and technical briefing documents; provides and supports a variety of tools for accelerated virtual package design and package testing; drives the flow of work in the artwork development; aids approval processes as well as the entire packaging and artwork-management process; and enables on-demand rendering of the artwork through the entire process. It's somewhat surprising that only 29 percent of the aforementioned survey respondents are using this technology today in any way.

Avoiding the write-off

|

According to the survey, packaging write-offs as a percentage of revenues are growing over time for most companies. The average value for write-offs in the most recent year among the respondents was 1.4 percent, an enormous waste number considering that the average revenue of responding companies was in the range of $10 billion. Yet a full 16 percent of the companies claimed packaging write-offs of more than 2.6 percent.

CPG companies that use PLM software minimize write-offs and other errors due to outdated specs or content. The PLM keeps the efforts of each player in sync, even as many things may be changing simultaneously, and can even encourage collaboration.

Conflicts between the objectives of different disciplines can be dealt with early on and at minimal cost. For example, the marketing leaders of a packaging design project may want a large front panel of a carton to convey maximum impact in the store aisle. Yet the manufacturing team on the same project may want a shorter carton to enable stability in manufacture. Sales needs the package to stay within the facing guidelines of key retailers to ensure maximum distribution. When all these requirements are in the systems and tagged to the same product, conflicts can be clearly identified. Using the information from the PLM, the CPG company can consider all stakeholders' requirements and size the box accordingly. Survey results indicate that many CPG companies plan to adopt PLM technology in an effort to improve the performance of their packaging and artwork management processes. Nearly 40 percent of the survey respondents plan to implement PLM technology within the next year; another 26 percent of respondents plan to evaluate PLM software in that timeframe.

Dan Staresinic is the worldwide director for consumer products and life sciences for Siemens PLM Software. For more information, visit www.plm.automation.siemens.com

You May Also Like