Because of today’s consumer trends of personalization and customization, as well as product proliferation and short production runs, we’re seeing a shift in packaging decoration technologies to more direct-package printing. Also, one workhorse labeling technology is shrinking while another one is set to rise.

Respondents to Packaging Digest’s exclusive Food & Beverage Packaging: 2016 Community Report, conducted this spring, answered a number of questions dealing with packaging issues, challenges and opportunities. One question centered on packaging graphics and decorating technologies. Specifically, we asked “When it comes to packaging graphics, which decorating technologies are food and beverage brand owners using and/or planning to use in the next two years?”

The different answers for each case—current use versus future use—show some interesting shifts in package decorating trends.

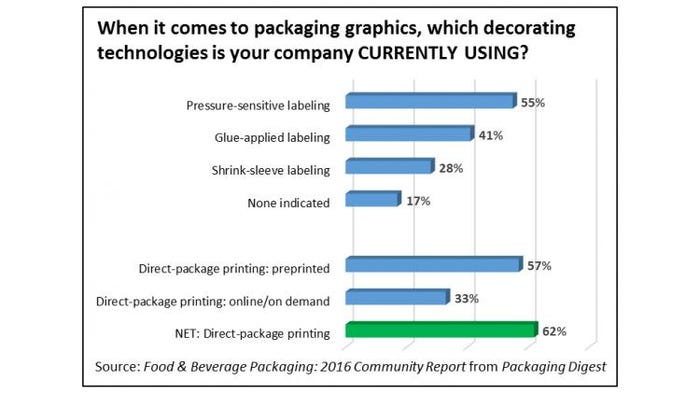

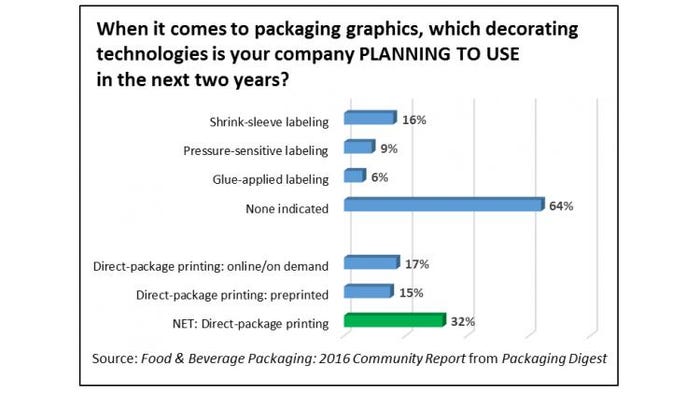

In both cases—current use and future use—“Direct-package printing” obtained the highest scores (62% and 32%, respectively), showing a clear preference by food and beverage companies for this decorating method.

Further analysis of the poll results also shows a possible advantage in the future for online/on demand direct-package printing compared to preprinted direct-package printing. The wider use of online/on demand direct-package printing is something I predicted as far back as 1999 because of the added flexibility this gives packaging operations for easier changeovers and the capability for personalized or custom graphics, a consumer trend we’ve seen already for several years that is continuing.

The percentage of respondents currently using “Direct-package printing: preprinted” is 57%, while 33% say they are currently using “Direct-package printing: online/on demand” technologies. The total net percentage of respondents currently using “Direct-package printing” is 62%.

When it comes to “Direct-package printing” methods for future use within the next two years, “online/on demand” (at 17%) takes the lead over “preprinted” (at 15%). “Online/on demand” direct-package printing also takes the lead over all other decorating methods included in this poll: “Pressure-sensitive labeling,” “Shrink-sleeve labeling” and “Glue-applied labeling.”

“Pressure-sensitive labeling” has a fair amount of market share today, with 55% of respondents saying they are currently using this technology. But future use is a bit questionable with the percentage of respondents saying they plan to use PS labels in the next two years in the single digits (9%).

A high percentage of respondents (41%) selected “Glue-applied labeling” for current applications, which is consistent with the number of processing plants equipped with high-speed roll-fed glue labelers, mostly for round containers such as glass or plastic beverage bottles and metal food cans. But, at a mere 6%, “Glue-applied labeling” pulls up the rear for decorating technologies that food and beverage respondents plan to use in the next two years.

While the market for “Glue-applied labeling” may be waning, the popularity of “Shrink-sleeve labeling” hasn’t peaked yet, as 16% of respondents say they plan to use this technology in the next two years. That’s the second highest decorating technology selected by packaging professionals in this poll, behind “Direct-package printing: Online/on demand.”

These shifts will also impact packaging operations and capital equipment expenditures as food and beverage companies invest in different decorating technologies in the next couple years.

Many respondents to this survey weren’t so forthcoming when it comes to what’s next, with 64% declining or unable to identify the technologies they plan to use in the near future.

Note: Percentages in the charts don’t add up to 100% because respondents were able to select more than one option.

This is just a fraction of the rich data contained in the Food & Beverage Packaging: 2016 Community Report. Other topics include vendor selection best practices, day-to-day challenges, automation technologies, social media use and useful resources. Click here to download highlights of the results of our exclusive research.

***********************************************************************************************

Looking to make a shift in your package decorating technology? Explore cutting-edge packaging, manufacturing and automation solutions from hundreds of exhibitors at MinnPack 2016 (Sept. 21-22; Minneapolis). Use discount code PDigest16 to get 20% off your conference registration.

About the Author(s)

You May Also Like