July 21, 2016

Two key principles guide brand owners in pursuit of “premium” appeal. The first is that packaging change is inevitable, constant and must be anticipated to ensure success. The second is the promise of premium packaging: that a product presentation that exceeds consumer expectations with an element of luxury goes a long way in solidifying brand loyalty.

However, the characteristics that constitute “premium” have varied throughout the years as consumer tastes and preferences evolve. Increasingly, premium packaging isn’t only synonymous with heavy-duty materials, but also sustainability and convenience. As brand owners aim to entice consumers with the “everyday luxury” of premium packaging, they must also pay careful attention to the latest consumer trends to strengthen their market share by capitalizing on the right materials and formats.

By working closely with suppliers, these companies will benefit from a constant stream of new technologies, including materials, containers, printing capabilities and the equipment to effectively handle it all.

Packaging as an everyday luxury

The idea of “luxuriating” a product through packaging certainly did not originate with the Great Recession. However, the economic downturn of the previous decade has offered the industry an opportunity to try a new approach. To innovate their product packaging and entice customers at a time when the over-all consumer attitude has been “save, don’t spend,” brand owners are re-energizing high-quality, affordable products by wrapping them in luxury packaging.

“People seek everyday luxuries to retain a certain standard while spending according to the ‘new normal,’ and we see this played out in packaging,” says William Cunningham, global marketing leader—packaging, DuPont.

For example, ready-to-eat and microwavable meals are a popular solution for dual-income families with little time to prepare meals at night. A product that typically is seen as a basic low-cost item has been reinvigorated as demand has increased due to economic factors. Seeing the potential of such products, brand owners have created packaging that enhances the attractiveness of quick meals. These days, quick meals are hardly recognizable as simply edible dinners that save time; luxurious packaging elements such as ceramic pots and compartmentalized containers, create an enhanced experience and support the feeling of a home-cooked meal.

New advances with existing packaging formats are enabling generic products like quick meals to shine on the shelves. The stand-up pouch continues to lead the way for design innovation focused on product differentiation and premium positioning. “Pouch fitments such as pour spouts and other converted features are increasing the utility of the package while the expansion of microwaveable structures is further enhancing the convenience of the standup pouch design,” says Chris Rempe, director of global marketing, Automated Packaging Systems.

The idea that everyday products can have a special and exclusive look through their packaging creates a consumer experience that imparts luxury and quality without compromising consumer wallets. DuPont’s Cunningham says, “The consumer mind-set that ‘it doesn’t have to be expensive to be special’ will continue to drive this trend.”

The stand-up pouch provides a premium look that is preferred by consumers and is fast becoming the standard for produce and foods. Technologies like the SidePouch stand-up pouch and the SidePouch FAS SPrint Revolution pouch-filling machine from Automated Packaging Systems allow brands to package these products in a highly productive and cost effective way.

Competition in the packaging sphere

Brands face fierce competition when it comes to premium packaging. Food-related consumer packaged goods companies (CPGs) are finding it particularly difficult to differentiate their products to consumers. However, the race to innovate has also led to the birth of some of the most creative packaging solutions to date.

“We see the food industry continuing to lead the premium packaging revolution. Package appearance and function are often the difference between success and failure. In essence, the company is selling the packaging as much as the product itself,” says Rempe.

To stand out, brand owners are making use of new materials to distinguish their products on the shelf. “The changes we are witnessing in the marketplace seem to be more than trends; rather, they represent seismic shifts in consumer preferences that are driving CPGs’ premium product and packaging development,” says Chris Voght, senior director of sales and marketing, Torayfan Div., Toray Plastics (America) Inc.

Advances in additive technology are helping to create unique packaging materials with distinct visual characteristics—plastic, for example, that looks like paper or even leather. Additives are also making it possible for packaging to take on tactile and aromatic dimensions that help set brand products apart.

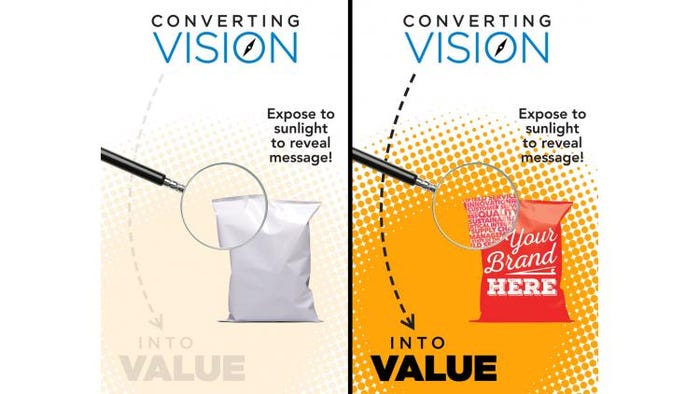

Snack foods—products the public generally sees as very accessible—are getting a dose of luxury with technology that is refining flexible packaging. Printpack, for example, is using proprietary technology that allows photochromic ink to be applied to packaging. The incorporated graphics remain invisible until exposed to sunlight.

“The process represents the first time photochromic ink has been applied to a flexible film, which gives brand owners, in any market capable of utilizing flexible packaging, new options for interacting with their customer base. This type of packaging application can truly set a brand apart by adding depth to the consumer experience,” says Mark Brogan, director of technology and innovation at Printpack. “It can make all the difference when it comes to purchasing decisions.”

Sensory enhancements on packaging appeal to premium-seeking buyers. For example, photochromic ink printed on flexible packaging, differentiating technology from Printpack, engages consumers by exposing invisible graphics when the package is in sunlight.

Premium packaging highlights function

It is not just aesthetics that set products apart in the marketplace. Functionality plays an important role in representing the brand and providing a premium experience for consumers.

“In terms of the packaging, we find that the CPG aims for the package not only to be part of the experience, but to enhance the experience overall; that can begin when the consumer engages with a product that stands out on the shelf. The construction of a package is key to differentiating a product and elevating it from ordinary to premium,” says Toray’s Voght.

According to Cunningham, a key area where DuPont is asked to support is easy-to-open packaging. Consumers demand on-the-go convenience, with packages that are fuss-free to open at the point of consumption, whether it is in the car, in the office, during lunch or after a sports game.

Easy-open features signal premium packaging to consumers. A sealing solution, such as DuPont Appeel, provides easy peel functionality with repeatable performance for all package forms—whether pouches, thermoformed trays, lidded cups or blister packs—in a range of polymer types.

Extending shelf-life is also top-of-mind for brands as they explore ways to “luxuriate” their products.

For example, brand owners look for packaging materials and designs that provide stronger barriers against oxygen and moisture. “To satisfy that requirement, CPGs are choosing clear, metallized and bio-based high-performance thin barrier films made with certain advanced coatings and sealants,” says Voght.

Voght notes that CPGs dealing with the challenges presented by evolving distribution channels and transporting goods in changing altitudes find premium value in materials like the new Torayfan Over-the-Mountain biaxially-oriented polypropylene (BOPP) films. “These high oxygen- and high moisture-barrier films use high seal-strength technology and hermetic-seal functionality to insure that bags stay sealed in those changing conditions, which also helps keep food fresh,” he says.

Lifestyle influences product packaging

With the recent economic fluctuations and the surge of Millennials who are continuously demanding more out of products, packaging that fits into an on-the-go lifestyle is particularly popular amongst consumers. “It used to be that smaller portions were simply ‘mini’ versions, but now we see them tailored to be more personalized experiences, wholly distinct from the family-sized offering,” says Cunningham.

Timm Johnson, vp of sales and marketing at Spee-Dee Packaging Machinery, has noticed a growing demand for single-serving, on-the-go packaging. “Major food manufacturing companies are looking for ways that they can package their single-serving products as the best quality products on the shelf,” says Johnson. “Not only are these portion sizes expected, but their packaging is expected to exemplify quality and functionality.”

Recently, Spee-Dee helped an oatmeal manufacturer “luxuriate” its single-serve oatmeal cups. Using Spee-Dee’s combination fillers, the company was able to package its product in a single-serve, premium cup that not only suited the on-the-go lifestyle, but was also able to incorporate complex ingredients, like fruits and nuts, into the cup. “The ability to include the ingredients that the oatmeal manufacturer asked for was very important to the product,” Johnson says. “With the additional ingredients in the new cups, the product was not only of the highest quality, but the packaging was able to support and illustrate the level of quality.”

Upscale single-serve oatmeal cups with extra ingredients like fruit and nuts were possible thanks to combination fillers from Spee-Dee Packaging Machinery.

Consumer expectation drives wellness and safety

The idea that premium packaging supports the product itself is especially important when it comes to the demand for healthy products. Cunningham believes the lifestyle packaging trend goes hand-in-hand with the explosion of wellness products now available. Not only must the portion size support a healthy lifestyle, but the packaging itself must be able to clearly communicate to customers what they are consuming.

“Consumers expect that relevant information supplied on the package—such as farm conditions for the product and animal provenance—can provide them a history and unique connection to their food.Plus, brand owners are able to offer consumers a more engaging experience and build greater brand loyalty,” says Cunningham.

According to Rempe, not long ago products like fruits and vegetables were packaged in inexpensive poly bags. Today, the vast majority are being packaged in eye-catching stand-up pouches that incorporate high-end printing.

“In the organic and health-conscious segments, we are seeing a trend to move away from the shiny stand-up pouches that have become so common in favor of matte finish structures. The matte finish look conveys a more environmentally sensitive message and premium appearance consumers of these types of products are looking for,” says Rempe.

No matter the market, attracting consumers’ attention with premium packaging can help boost sales. Easy open, sensory or otherwise enhanced packaging designs communicate an everyday affordable luxury. Put them to good use!

Maria Ferrante, senior director, marketing and communications, PMMI, The Assn. for Packaging and Processing, is an award-winning media editor covering the processing and packaging industry for more than 20 years. At PMMI, Ferrante has spearheaded the association’s education and workforce development programs, collaborated on the development of industry standards and produced several conference programs, including the Innovation Stage program at PMMI’s Pack Expo portfolio of trade shows. Prior to joining PMMI, she was the managing editor of Food Engineering and Food Engineering Intl.

The companies highlighted in this article are participating at Pack Expo Intl. 2016 (Nov. 6-9; Chicago):

Automated Packaging Systems, Booth #S-2438

DuPont, co-sponsor of the Pack Gives Back charity event featuring magician-comic duo Penn & Teller

Printpack, Booth #N-5332

Spee-Dee Packaging Machinery, Booth #N-5436

Toray Plastics (America) Inc., Booth #N-5879

*****************************************************************************************************

Explore cutting-edge packaging, manufacturing and automation solutions from hundreds of exhibitors at MinnPack 2016 (Sept. 21-22; Minneapolis).

About the Author(s)

You May Also Like