The top winners in this year’s Institute of Packaging Professionals (IoPP) AmeriStar Package Awards Competition showed the rest of us how it’s done, combining innovation with practicality and design creativity with real-life usability.

The Best of Show Award went to Locked4Kids, for its child-resistant, senior-friendly drug package; Eaton’s Neo-Ray light fixture package was awarded the Design Excellence Award; and Sealed Air took home the Sustainable Packaging Award for its curbside-recyclable TempGuard Insulated Liners.

The AmeriStar judges considered more than 80 packages in the 2017 competition. Their judging criteria included packaging innovation, product protection, performance, environmental impact, economics and marketing. See all the winners here.

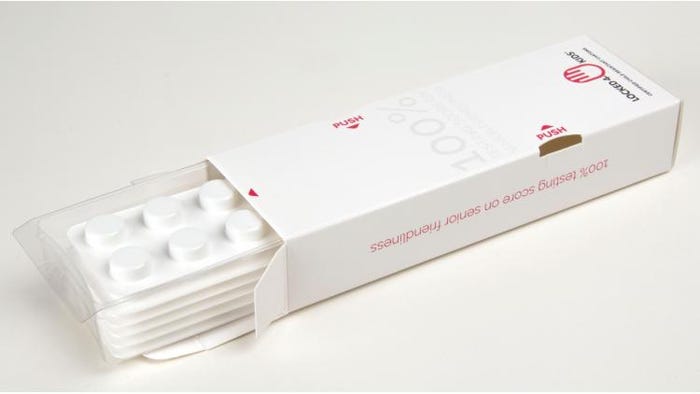

Best of Show: Locked4Kids certified child-resistant and senior-friendly reclosable package

Locked4Kids, an entrant in the drug and pharmaceutical category, won Best of Show this year. The Best of Show Award “honors a package that surpasses all judging criteria and that [the AmeriStar] judges unanimously rated ‘outstanding’” on all criteria, according to IoPP. Locked4Kids’s award-winning package is child resistant (CR), senior friendly (SF) and reclosable.

The package’s primary CR feature has a squeeze-and-pull design: The consumer must press two tabs simultaneously to access the medication inside the carton. Watch a demonstration here. Locked4Kids’ unique twist on the design is to place the tabs diagonally on either side of the carton, far enough apart that a child’s hand cannot span both tabs.

Consumers press the tabs with one hand, and use their other hand to slide a plastic tray out of the carton. The tray holds medicine in a blister pack or other pack format. The package structure locks the filled tray into the carton and also locks the blister packs into the tray. To provide an extra layer of child resistance, the carton material incorporates a high-strength, tear-resistant film lamination that withstands tearing and biting. The package has an F=1 certification for child resistance.

And yet the package is easy for adults, including seniors, to use. Very little grip strength is required to press the squeeze-and-pull tabs, and an adult’s hand can easily reach both tabs. In tests, 100% of seniors opened the package on the first try and with no instructions.

“The most challenging element of the design process was the fine-tuning to achieve a very high score on Child Resistant whilst maintaining a 100% score on Senior Friendliness,” says Iwan Heynen, technical director at Locked4Kids. “We continued this process even after the package was certified, which is the AmeriStar-winning Locked4Kids version 2.0 package.”

Notably, the package is compatible with high-speed production. “The most innovative element is the fact that the CR/SF packaging platform is based with a ‘standard’ folding carton,” Heynen says. “This allows the drug manufacturer and packager to efficiently fill the cartons with their existing cartoning equipment, which minimizes the time, space and investment involved with adopting a new package format.”

He adds, “On the materials side, most folding carton converters have the capability to make the Locked4Kids cartons, which allows supply-chain efficiency.” Both the carton and tray are recyclable.

The package concept can also be used for many types of products.

Locked4Kids is based in The Netherlands and operates a Delaware-based U.S. subsidiary.

Next: Eaton’s Design Excellence Award

***********************************************************************************************

Create your own award-worthy package with help from leading suppliers. Find them at PackagingDigest.com/Directory or meet them in person at MinnPack 2017 (Nov. 8-9; Minneapolis), which is celebrating its 15th year. Register today!

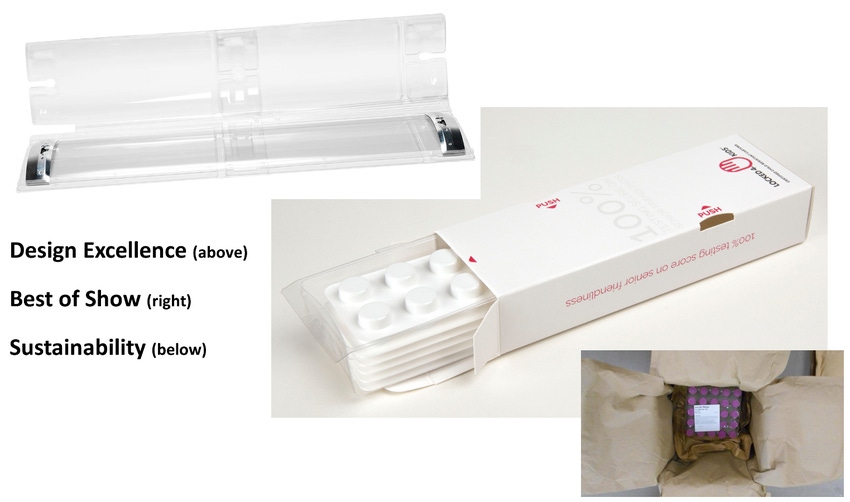

Design Excellence: Eaton’s Neo-Ray Light Fixture

Eaton’s Neo-Ray Covera light fixture package won the 2017 AmeriStar Design Excellence Award, which recognizes the package that best integrates structural and graphic design. The package, a rigid clamshell designed and manufactured by Transparent Container Co., protects clear acrylic light fixtures from the time they’re manufactured until after they’re installed at a buyer’s construction site.

At the Eaton plant, Neo-Ray fixtures are packed in a 30-mil recycled polyethylene terephthalate (rPET) clamshell prior to quality-control testing and shipping. While still in their clamshells, the fixtures are installed at the customer’s work site and tested again by the contractor. The fixture’s low-voltage suspension cables pass through penetrations in the ends of the clamshell, enabling installation.

The packaging is not removed from the fixtures until construction is completed, which shields them from scratches, fingerprints and other damage. In addition to protecting the fixtures during shipping, the clamshell protects against rough handling and exposure to construction dust at the work site. Removal of the clamshell is easy and requires no tools.

Thanks to a modular package design, Eaton can use the same clamshell for 2-foot- and 4-foot-long Neo-Ray fixtures. Each clamshell is designed for a 2-foot fixture, but a pair of clamshells can be snapped together, end to end, to create a package for the 4-foot fixture (shown in the picture).

The lightweight clamshell eliminates the need for numerous packaging components—foam blocks, plastic bags and slip sheets, for example—that would typically be needed to protect the fixtures from impact, dust and other sources of damage.

Visually, the clamshell complements the contemporary, upscale Neo-Ray brand image. The colorless, transparent clamshell provides architects and other commercial buyers with a clear view of the fixture’s design and showcases the clarity of its acrylic lens.

The package is recyclable, and its standard-grade rPET substrate includes post-consumer recycled plastic. Transparent Container Co. supplies Eaton with the clamshells.

Finally: Sealed Air’s Sustainable Packaging Award

***********************************************************************************************

Create your own award-worthy package with help from leading suppliers. Find them at PackagingDigest.com/Directory or meet them in person at MinnPack 2017 (Nov. 8-9; Minneapolis), which is celebrating its 15th year. Register today!

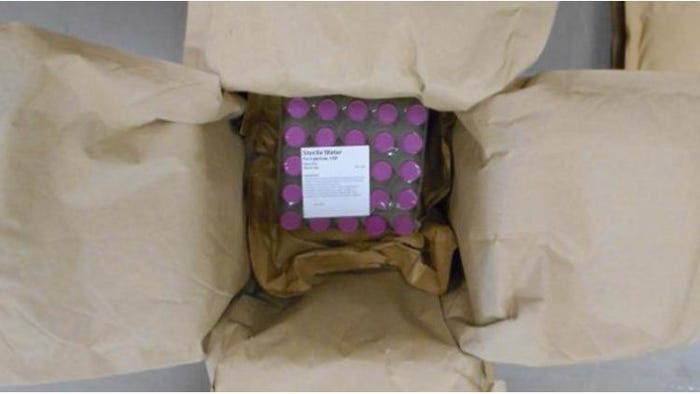

Sustainable Packaging: Sealed Air’s TempGuard Insulated Liners

Insulating, paper-based box liners from Sealed Air Corp. took this year’s Sustainable Packaging Award, which recognizes resourcefulness vis-à-vis environmental impact, energy use, recycling and reuse characteristics, and overall eco-friendliness.

Sealed Air’s TempGuard Insulated Liners shine on all these dimensions. In contrast to polymer-based insulating materials, the TempGuard liners are reusable and 100% curbside recyclable. They’re made from durable 50-lb. Kraft paper, with uniform inner padding composed of 100% recycled paper fibers, including 25% post-consumer content.

“The most innovative feature of TempGuard is its recyclability. It’s an all-paper, curbside-recyclable solution that provides thermal protection tailored to meet individual customer needs,” says Chad Stephens, Sealed Air vp of R&D.

The liners protect products from both heat and breakage. They provide more than 48 hours of insulation for perishable items, pharmaceuticals and other temperature-sensitive products, creating a stable thermal environment from the warehouse to the goods’ final destination.

TempGuard liners have a (thermal-resistance) R-value of 3.70 per inch, which is similar to that of expanded polystyrene (EPS) and better than that of polyethylene (PE) foam. As an added benefit, the liners absorb condensation inside the packed box, which helps keep products dry.

Because the liners are cushioned, they protect products from impact during shipping and handling. They are also flexible and can be wrapped around box contents to reduce movement inside the box during distribution.

The liners are stored and shipped flat, providing space efficiencies versus foam coolers. According to Sealed Air, space efficiency increases 400% with the liners versus unibody EPS or polyurethane (PU) coolers. Packing more liners into every truck reduces carbon footprint, and the flat format provides packagers with reduced freight and warehousing costs.

The pre-made liners come in four sizes and can be used inside corrugated boxes or other packaging. The cost for a 12-inch x 50-inch liner, for use in a #10 size box, is about 70 cents.

***********************************************************************************************

Create your own award-worthy package with help from leading suppliers. Find them at PackagingDigest.com/Directory or meet them in person at MinnPack 2017 (Nov. 8-9; Minneapolis), which is celebrating its 15th year. Register today!

About the Author(s)

You May Also Like