March 11, 2015

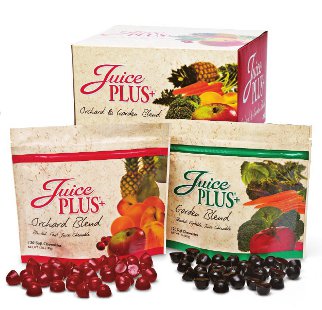

JuicePlus_pouches and box

After finishing a reformulation project of its gummy-style nutraceutical, National Safety Assoc. (NSA) LLC., Collierville, TN, was challenged to find a way to deliver this higher quality product, which also cost more to manufacture, to the marketplace.

"We've been working for a couple of years on a new formula to reduce the sweeteners and also, if possible, eliminate gelatin because it's not a natural fruit or vegetable-based ingredient," remarks John Blair, senior vp of product and research for NSA. "[The new formulation] got a substantial reduction in the amount of sugar, basically 40 percent reduction in the sugars, and we were able to develop a product using pectin, which is a fruit-based binder that essentially replaced the gelatin. The only problem was that the formulation was much more expensive, and given our current environment, we are very sensitive to the retail cost of our product and did not want to increase the price at all."

To deliver the new formulation, which NSA was determined to do, the company looked at multiple avenues to offset the higher manufacturing costs. At the helm of this search was NSA director of product development Elizabeth [Liza] Pepple.

"Liza came from ADM [Archer Daniels Midland Co.] on the ingredient side," Blair explains. "She has the industry experience, knew a lot of suppliers, knew our manufacturers, and had and has a good understanding of the dietary supplement industry."

Packaging, though, was not this chemical engineer's strong suit. Luckily, NSA had recently acquired some packaging talent at the C-level. "Our new COO came from Bryce Corp.," Blair explains. "He knew of John Fulcoly from his previous experience [at the flexible packaging supplier.]"

Fulcoly is the principal of Packaging CPR (Client Productivity Resources) and holds a master's degree in packaging science from Michigan State University in addition to approximately 20 years of experience working on packaging projects for Frito-Lay.

"Fulcoly taught me quite a lot about the packaging side of things," Pepple remarks. "His help was invaluable in getting the project moving."

And they moved quickly. Fulcoly was brought onto the project in March of 2009, and the reformulated and renamed product in its new packaging rolled out a mere seven months later.

Bagging productivity gains with style

Supplied by American Packaging Corp., the new packaging is a gusseted stand-up pouch made from matte polyester that is adhesive mounted to a metalized polyester, then adhesive mounted to a PE sealant film. Blair notes that this packaging format already is associated by consumers with produce as it often is used for dried fruit.

"This is the package that sits on the shelf or the kitchen counter for all of our consumers, so it's important to us that we present a consistent and quality image to properly position the product. What we don't want to happen is that someone would be convinced to buy the product and then when they receive it be disappointed with that initial impression," he explains. "Packaging is very important in terms of our image and message."

Additionally, Blair remarks, the market for NSA's chewable nutritional products have changed. "They are primarily designed for kids, but it turns out that people of all ages like the product and take the product," he says.

The new packaging format enables NSA to adopt the more mature packaging design that was recently launched by the company for its Juice Plus+ capsules. This design, which was developed and refined with the help of Lee Weeks, graphics manager at Natural Alternatives Intl., uses vibrant photography to depict the fruits and vegetables that are used to make Juice Plus+ products. (See "More than a pretty face," Packaging Digest, April 2010.)

The pouches are manufactured at American Packaging Corp.'s Flexographic Printing and Laminating (FP&L) facility in Story City, IA. The 220,000 sq-ft facility houses a variety of equipment for flexographic printing, adhesive laminating, bag and pouch fabrication and more, but the division specializes in packaging for products that require demanding performance properties along with flexographic printing of up to 10 colors.

Bill Moses, American Packaging Corp. director of business development, remarks that the facility has been making pouches for Juice Plus+ Chewables since spring 2010 on various presses throughout the facility. Most recently, though, FP&L has been using its multicolor flexographic presses from Windmoeller & Hoelscher Corp.

Zipper choice a challenge

While Fulcoly acknowledges American Packaging Corp.'s printing prowess-noting that matte polyester is a "tricky" material-the consultant says it was the converter's postpress capabilities that stood out for him.

"This is not like a bag of chips that you're paying 99 cents for," he remarks. "We had to have a very clean, perfect opening on the tear and we needed to have the zipper durability to open and close multiple times."

To get this perfect tear, American Packaging Corp. laser-perforated the film while it was still a web of material versus finished pouches.

Finding the perfect zipper would prove to be a more difficult challenge. "We tried about 14 different kinds of zippers," Pepple notes.

"In one of our first meetings with the packaging supplier, they had a notebook about 4-in. thick with various zipper designs, and various backing materials, various widths, various flange designs," Fulcoly adds. "We narrowed down the selection to four zippers that we thought had a real, audible ‘pop' when you close it.

"The one that we started out with, though, created a problem because it required a very high temperature to seal to the packing material," he remarks.

"This created wrinkling problems in the appearance of the pouch," Pepple adds. "And not only wrinkling but the heat that was needed to put the zipper in was so high that it was creating some scorching."

The problem was resolved by moving to a Presto Products Co. Fresh-Lock Style 106 closure. This LDPE zipper features patented sealant ribs that enable lower application temperatures and faster line speeds. The lower sealing temperatures reduce film distortion for an improved package appearance.

Fulcoly notes that zipper integrity is not hampered by the lower temperature application because, "it also had a very strong [adhesive] sealant so there would be no chances of the zipper coming unsealed from the packaging material."

After manufacturing the pouch, American Packaging Corp. ships the pouches to NSA's contract manufacturer in California. Previously, this contract manufacturer only made the product then shipped it to a contract packager in the Midwest that specialized in hand-packing products in a clean-room environment.

As Fulcoly tells it, when he observed the packaging process for the previous product formulation, which was sold under the name JP+ Gummies, he was struck by its complexity. The results, he noted, didn't reflect the extra cost and effort put in the process and looked more like "me-too" packaging that could have been used for a multitude of other nutritional products.

With the new standup pouches, the copacker is able to both manufacture and package the product, now sold under the name Juice Plus+ Chewables. This removes the environmental impact of shipping product halfway across the country and lops a significant chuck of time off of the nutraceutical's production cycle.

"We cut cycle time down by a month," Fulcoly explains. "The previous packaging had a label, jar, liner and cap, and there was a packaging process, a shipping process and a product-making process. We narrowed that down to a pouch and a carton, and the supply chain became a whole lot easier to manage."

Carton offers protection

The packaged products still needed to be shipped to the consumer, though. "There were two unique pressures on this packaging development project: One was the high value and high selling price of the product, which required this very high-value pouch, and the other was that the product is delivered through UPS distribution," Fulcoly recalls. "So we needed a carton that could protect the product whether it was right side up, upside down, on its side, nicely handled or ‘unnicely' handled."

To this aim, NSA and Packaging CPR charged Malnove Packaging Solutions with creating a custom carton structure that is strong but not excessively bulky. The solution was a paperboard carton converted with a divider inside that helps keep the carton rigid and stable.

Further sustainability savings are realized by elimination of specialized shipping cartons for summer deliveries. "The new packaging and the new formulation combined are much more resistant to the weather," Blair explains. He estimates that approximately 176,000 shippers with foam inserts have been eliminated annually-dropping the environmental impact of shipping Juice Plus+ Chewables by half in the summer. Overall, Blair says the company expects to save 33 tons of total packaging materials annually.

Not only did the packaging reductions result in a huge win sustainability-wise, it also greatly impacted the production costs for the product-in a positive manner. Describing how the packaging and process savings affected Juice Plus+ Chewables' production costs, Fulcoly says, "If this didn't fund it all, it funded almost all of it."

The plusses keep rolling in

"Sales doubled," Blair explains. In addition to graphics that are more consistent with product branding across the line, the new pouches also have a structure that offers more branding space. "[The pouch's billboarding area] is much better than the jar, where you've got a wraparound label," he remarks.

The success of the Juice Plus+ Chewables project has NSA now scrutinizing its other products' packaging.

"We, like many other companies at this time, have a ‘green' committee and are trying to make improvements in that area," Blair explains. We're now looking at [the plastic containers used for] the capsules in a new light." The company also is looking at the rigid packaging used for its Juice Plus+ Complete powdered beverage product that is used as meal replacement, pre- and post-workout beverage or a snack. But Blair hints that the first extension of this project might be much smaller-a sample pack to launch early this year.

American Packaging Corp., 515/733-1400. www.ampkcorp.com

Malnove Packaging Solutions, 801/773-7400. www.malnove.com

Natural Alternatives Intl. Inc., 800/848-2646. www.nai-online.com

Packaging CPR (Client Productivity Resources), 214/728-1246. www.packagingcpr.com

Presto Products Co., 800/265-0750. www.fresh-lock.com

Windmoeller & Hoelscher Corp., 800/854-8702. www.whcorp.com

About the Author(s)

You May Also Like