August 1, 2017

IC Optix's label magnification technology is several steps closer to appearing on pharmaceutical and medical device labels. The company has been working closely with security solutions provider Securikett to optimize the integration of the lens film into finished label constructions and to scale up label production, reports Jim Rittenburg, co-founder of IC Optix. The lens can be positioned by users to magnify text on labels, cartons, and other packaging formats. "In terms of user functionality, the labels provide a convenient vision aid that is available for use by the patient or consumer if they are unable to read important information on the product package or label," he tells PMP News.

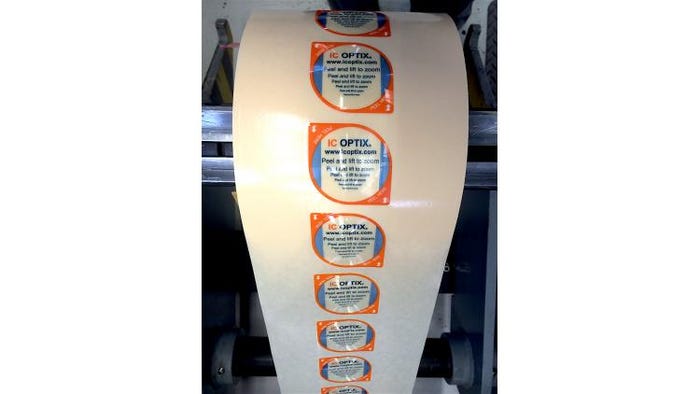

Rittenburg was on hand at Securikett's Interpack booth earlier this year to provide attendees with an update on the technology, which has been tested on standard label production lines. "We've done our trial work using conventional flexo presses," he says. "We've had no issues, even at scale. It's similar to converting a holographic label."

The solution consists of a standard polyester label material (PET) in a multilayered structure that serves as a magnifying lens that can be added to labels, cartons, and more.

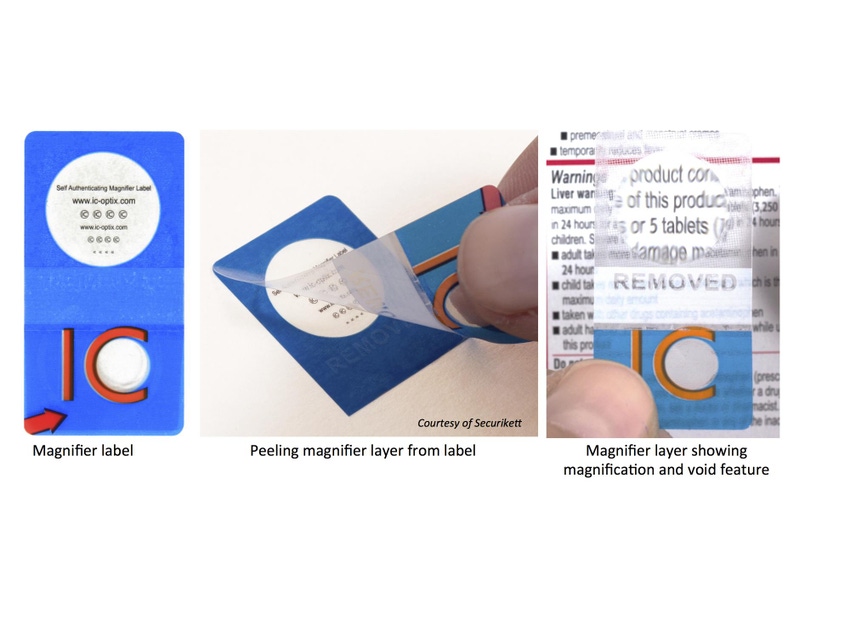

"The magnifier film is manufactured using a reel-to-reel system, making the lens layer highly compatible with conventional label conversion and manufacturing processes," he says. "In working with Securikett we have taken it a step further by integrating the magnifier film into various tamper-evident label constructions. The result is a functional, high-security TE label with striking overt user facing features including magnification and visual void effects." For instance, the labels integrate void features that make it difficult to remove or destroy the label.

Rittenburg also calls the magnifier technology rugged. "It is like any other PET film," he says. "It is not fragile or susceptible to damage if wet or wiped."

It's also pretty powerful in terms of magnification. "Some of the lens structures we have produced have sufficient magnification to read the microtext typical on currency," he adds.

Above: Eye-shaped magnifier labels from IC Optix

They also offer an element of product security. "These labels provide a unique combination of user functionality and product security," he says. "The magnifier labels provide a unique user-facing feature that contains the thin magnifier, which is very difficult to copy due to the depth and radial nature of the structure. The magnifier feature provides a 'value add' to the end user who benefits from the vision aid, while at the same time the presence of a functional lens helps confirm authenticity of the package. To further enhance the product security aspect of the magnifier film, other optically variable microstructures are integrated into the magnifier film as part of the same proprietary manufacturing process used to produce the lens."

Above: IC Optix magnifier labels on press.

Rittenburg has seen interest from brand owners with products in healthcare (both Rx and OTC including supplements), medical device (such as contact lenses and solutions), personal care, and others. He cites a few reasons for the interest in integrating a magnifier lens into such packaging.

"Firstly there is a large and rapidly growing demographic in the age group of 40 years and older that experience loss of near vision due to the natural effects of aging on the flexiblity of the eye’s lens. This demographic currently includes over 320 million people in the U.S. and Europe and over 1.8 billion people worldwide," he explains. "Multiple surveys have shown that more than 80% of people in this demographic have difficulty reading important information on product labels. Secondly, trends in packaging including sustainability initiatives, multilingual requirements, and growing regulatory requirements for warnings and product information, have resulted in smaller package sizes carrying increasing amounts of information. Medicines and other healthcare and personal care products are often packaged in relatively small bottles, blister packs, and boxes that have limited real estate for printed information. The inevitable result is that text is printed in small font sizes and appears crowded, making it very difficult to read. This leads to medical errors that result from people misreading, or not bothering to read, important information such as warnings and instructions for use."

In addition to the magnifier film's potential for pressure-sensitive label applications, it can also be integrated into hang tags and as magnifier windows in cartons or other packaging, he says. The film is also being integrated into pens and other devices as a retractable banner that can be scrolled in and out to provide a convenient magnifier, he adds.

*****************************

MinnPack 2017 (Nov. 8-9; Minneapolis) celebrates its 15th year to bring you the latest developments in all things packaging as part of a comprehensive advanced manufacturing event. Sign up today to attend!

About the Author(s)

You May Also Like