New England Biolabs’ new ClimaCell cold-chain shipper maintains a strict temperature-controlled environment to protect the company’s sensitive biological materials, which are sent to life-science researchers across the country.

Given today’s global pandemic coupled with growing environmental concerns, how are healthcare’s most vital products being safely and reliably delivered? And how it this being done sustainably?

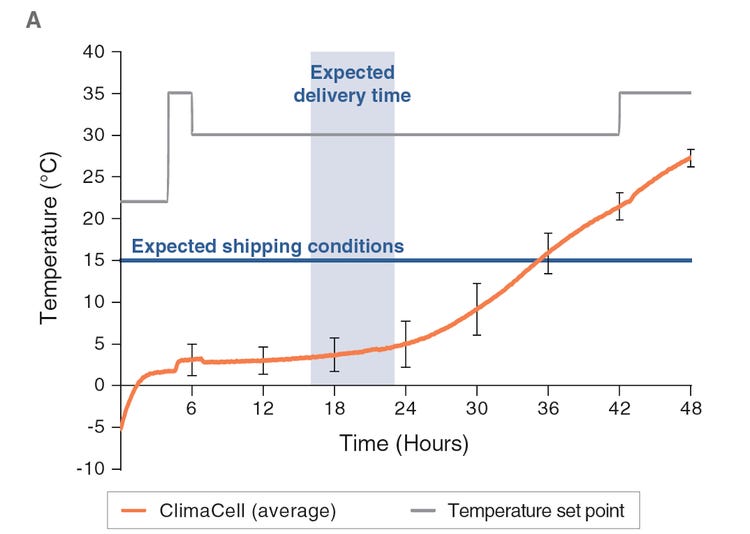

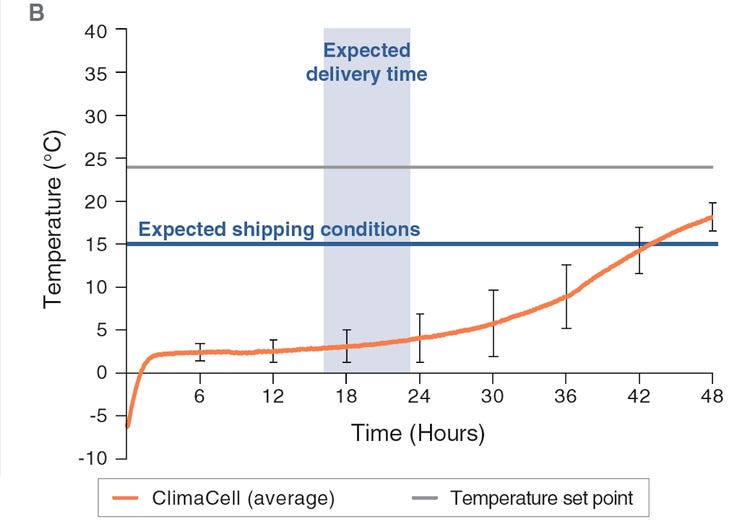

New England Biolabs (NEB) has found one such solution with ClimaCell from TemperPack, which is sourced by UPS Healthcare as part of its supply chain solutions for pharmaceutical, biopharma, and medical device companies. ClimaCell is plant-based, curbside-recyclable insulation that protects controlled room temperature (CRT) and refrigerated/frozen pack-outs for up to 36 hours.

“Our products being mostly biological materials, we ship to life-science researchers at laboratories around the world,” says Deana Martin, NEB’s marketing communications associate director. “Maintaining shipping temperature conditions is critical, particularly when shipping long distances or to warmer climates. We offer overnight delivery to most US locations, with an expected delivery time of 18 to 24 hours — well within the ClimaCell recommendation.”

The value of recyclability.

ClimaCell is repulpable alongside corrugated board, a product that is recycled 93% of the time, according to the Corrugated Packaging Alliance. TemperPack worked closely with Closed Loop Partners, a firm that helps develop products and practices that support a circular economy, to ensure ClimaCell meets all of the needs of both materials recovery facilities (MRFs) and paper manufacturer companies.

During repulping, the bio-based starch insulation dissolves and useful kraft paper fibers are retained for reuse. As a result, ClimaCell is OCC-E certified curbside recyclable. It’s the first thermal insulation to receive the “Widely Recyclable” designation from How2Recycle. This label informs those receiving a ClimaCell-protected shipment that it can be easily disposed in curbside recycle bins alongside the corrugated box or paper bag it came in.

ClimaCell offers an alternative to expanded polystyrene (EPS) materials typically used for temperature-controlled shippers. EPS is inexpensive and provides product protection on top of temperature control. But it’s carcinogenic, oil-based, emits high CO2 levels, and doesn’t completely break down. Consequently, some healthcare-related organizations have taken a leading role in shifting to more eco-friendly packaging materials.

“EPS is difficult to recycle,” Martin says. “New England Biolabs has been very pleased with the ClimaCell insert and has received much positive feedback from our customers. We created an introductory video about ClimaCell and how it can be recycled. It’s available by scanning a code on the box, as well as on our website.”

Recyclable solutions for healthcare companies.

“Healthcare and life-science customers are requesting more sustainable packaging options,” says Wes Wheeler, UPS Healthcare president. “ClimaCell aligns with our commitment to a reduced environmental footprint across our healthcare logistics operations.”

UPS collaborated with Richmond, VA-based TemperPack to develop four off-the-shelf outer packaging models of varying payload sizes for pharma and biopharmaceuticals, specimens, diagnostic reagents, and vaccines. Small package containers use its ClimaCell material.

These additions to the UPS Temperature True portfolio give healthcare and life science organizations more sustainable options: They’re expected to keep tens of thousands of foam shipping coolers out of landfills over the next several years.

“Each of the UPS packaging levels produces considerably less CO2 emissions than EPS,” says TemperPack co-CEO James McGoff. “They maintain a high degree of rigidity, durability, and product safety for highly-sensitive, temperature-controlled products.”

As a bonus, ClimaCell box liners ship and store flat until you’re ready to use them, saving on freight costs and warehouse space. Assembling an insulated shipper is extremely easy. TemperPack Marketing VP Jed Dutton reports that ClimaCell is customizable in relation to both its thickness and density — some extending the same sort of climate protection for up to 48 hours.

Diplomat Specialty Pharmacy (soon to be Optum Specialty Pharmacy) is another TemperPack customer.

About the Author(s)

You May Also Like