InSphero’s InFloat shipper leverages ancient seafaring technology to keep products properly oriented throughout supply chain distribution. The shipper also maintains steady pressure and temperature for cold-chain and air freight shipping.

InSphero’s clever InFloat shipper keeps contents upright, regardless of package orientation. Designed to ship microtissues to global bio/pharmaceutical companies and academic laboratories, the gyroscope-looking floating ball also maintains an internal package temperature of over 20°C and less than 40°C year-round. And the contents are able to withstand pressure changes in airplane cargo compartments.

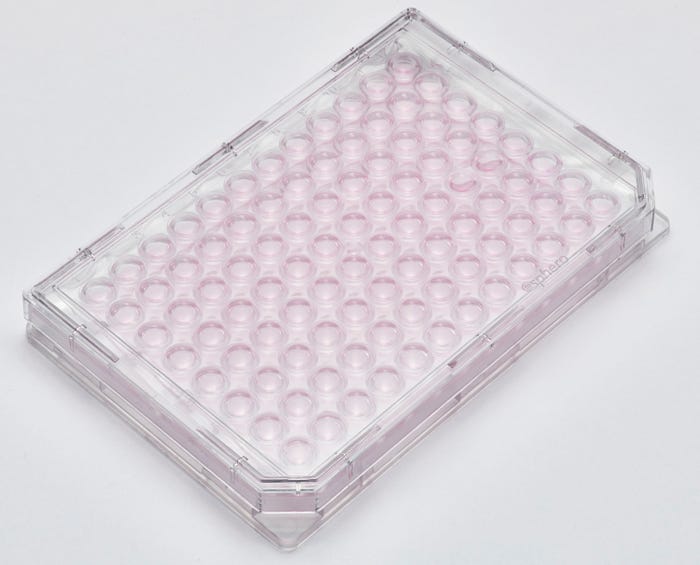

InSphero is the world leader in engineering highly specialized and functional 3D microtissues for drug discovery. Being very delicate, the microtissues ship in plates consisting of 96 or 384 tiny wells to researchers and drug screeners. Preserving the plates’ physiological function during shipping is not trivial.

Keeping the microtissue plates completely vertical is essential during transit. But despite “Keep Upright” arrows affixed all over them, packages can be subject to a multitude of shocks and are sometimes flipped in many directions.

“One of the biggest challenges of shipping live 3D cell cultures is that we can’t control what happens to our boxes of microtissues after they leave our bioproduction facilities,” says InSphero CEO and co-founder Jan Lichtenberg, Ph.D.

Inspired by seafarers who added keels and counterweights to vessels to prevent them from capsizing, InSphero’s radical innovation uses a similar principle — one that has never before been implemented in a packaging solution.

Says Lichtenberg, “Our InFloat shipping system reduces shipping risks and uncertainty by allowing our carefully packaged plates of microtissues to literally float safely on water until they reach their destination.”

In this video, Dr. Olivier Frey demonstrates how the shipper keeps live microtissues upright during transit.

Frey, Ph.D. and InSphero’s head of technology and platforms, and InFloat design team project lead, also answers Packaging Digest’s questions about this clever concept and its potential for broader application for other products and markets.

Why did you develop this packaging yourselves instead of working with a packaging supplier?

Frey: InSphero invented and patented its concept, then approached a supplier for final implementation after having internally demonstrated its feasibility. The InSphero InFloat shipper has been developed with and is manufactured by Taracell AG (Künten, Switzerland), a company specializing in particle foam packaging for sensitive shipments.

Will you license the InFloat shipper technology to other companies?

Frey: Yes, we are in the process of establishing an InFloat shipper licensing strategy, as well as an adapted version based on the same concept.

How long can the 3D microtissues survive in this package? Is there a time fudge-factor built into the packaging system to prevent the product from becoming unusable?

Frey: Our shipper is qualified for up to three days, and we aim to have microtissues arrive within two days for shipments to the US (three days for Japan). This is heavily dependent on the lifetime of the microtissue because they are not oxygenated during shipment.

One shipper was held up at a logistics center for one week due to a Boston snowstorm. When it arrived at its destination in Brunswick, Maine, the shipment of plates remained intact. The cargo was a different product (not live microtissues) but our shipper remained functional.

How much does the InFloat shipper cost?

Frey: The InFloat shipping system is not sold separately. The price is included in the overall cost of shipping to our partner laboratories. It is part of our “assay-ready” solution for pharma and biotech partners who purchase our 3D in vitro models for use in their labs. InFloat was specifically engineered to keep microplates of 3D models upright and secure during transport to labs around the world.

What sizes are available for this shipping container and why those?

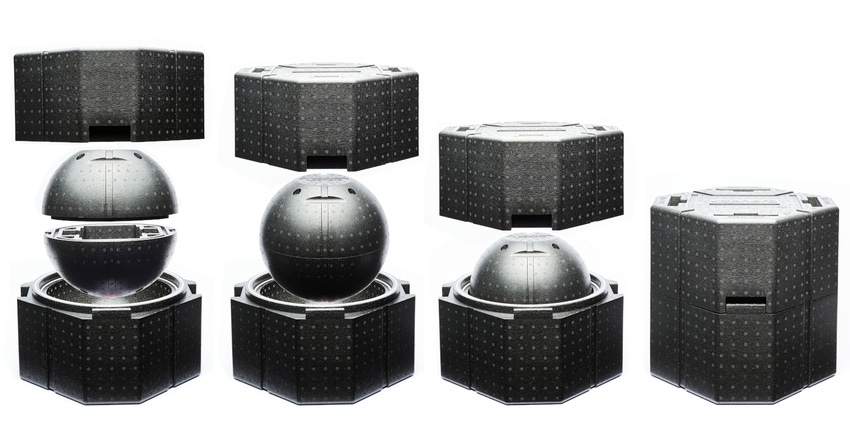

Frey: The InFloat shipper is currently available in one size only. It is sized to fit the four main components of the packaging system:

1. 3D microtissues sit in the company’s Akura assay plate technology, sealed with a film in sterile conditions. These plates are wrapped in a small plastic bag to maintain sterility. Depending on the customer order, two or more plates may be placed inside a small paperboard box.

2. The microtissue box sits inside of the sphere, which opens in half. Within it are thermo packs, gel packs, and two heating elements for temperature control. The sphere is securely closed by a single plastic strap.

3. The sphere sits inside the larger rectangular expanded polypropylene (EPP) box, floating on 0.5 liters of water. It has handles for easy carrying and opening and plastic straps for secure closure.

4. The EPP box is then housed in a large corrugated shipper — which also contains cell culture media — but can be shipped without the latter.

Interior dimensions and features have been specifically designed for sending microtissue boxes. But the overall concept can be easily resized and adapted for other goods.

About the Author(s)

You May Also Like