January 29, 2020

New trends in pharmaceutical packaging follow developments in emerging markets, demographic changes and new technologies—and that includes holography, says chairman of the International Hologram Manufacturers Assn. Paul Dunn.

With predictions that the global market for anti-counterfeiting packaging is set to reach almost US$250 billion by 2026, growth in pharmaceutical packaging authentication and anti-tamper devices appears to have a healthy future. This comes on the back of a rise in global healthcare concerns, higher adoption rates of anti-counterfeit technologies, and greater awareness of the benefits of new track-and-trace technologies and system integration.

Packages with security devices can ensure quality, and check the distribution and smuggling of illicit products. Items not displaying security devices, such as holograms, can be quickly seized and destroyed or exploited. Today, we are seeing advances in application, film coating and manufacturing technology, which is rolling back the boundaries for the use of a new generation of advanced holograms, facilitating fresh levels of visual effects, brand enhancement, regulatory compliance and anti-counterfeiting.

Since Glaxo first applied them to seal packs of Zantac in 1989, holograms have been taken up in a big way by the healthcare and pharmaceutical sectors. The ability of the hologram to provide effective protection lies in its continuous innovation and integration with other technologies—to the point where continuous evolution in techniques has succeeded in creating increasingly complex hologram-based devices that are easily recognized yet difficult to copy accurately.

For example, MediPharm’s anti-counterfeiting hologram technology is “only visible to informed experts,” the company claims. Developed to enable manufacturers, suppliers and patients to improve their packaging security, the seal displays an irreversible holographic effect when opened for tamper evidence and anti-counterfeiting protection.

Elsewhere, holographic foils can be used to great effect to differentiate product at the point-of-sale: something Colgate-Palmolive recognised when it launched its new “Total and Whitening” range of branded toothpaste into an already crowded marketplace. Aimed at the premium end of the market, Colgate-Palmolive needed its high-quality brand to stand out from the volume market.

The consumer giant uses holographic foil to strengthen the high-quality values of the “Total and Whitening” brand while ensuring the packaging catches the eye of consumers scanning supermarket shelves. The distinguishing visual effects holography brings were identified as a powerful tool in building a strong and powerful message—and reflect a premium value. The visual value the foil adds to brand messaging is difficult to pin down but certainly helps to contribute to the brand’s position as a sector leader, instantly recognisable on retailers’ shelves the world over.

Evolving role

The evolving role of the hologram has also been accompanied by the increased use of the security device in combination with other authentication technologies. Track-and-trace solutions identify the origins of a pharmaceutical industry product and verify its authenticity, thus fighting against counterfeits.

Optical security technology has advanced to such a position that, when it’s integrated with track-and-trace, it can provide manufacturers with the tools to be fully compliant with the forthcoming legislation (by November 2020, pharmacies can buy only products that are encoded with product identifiers mandated by the Drug Supply Chain Security Act). Beneficial features incorporated can help users generate unique sequential, encrypted or random serial numbers, or identify and mark products overtly or covertly either via special self-adhesive labels or directly onto pharmaceutical products using a variety of print technologies.

____________________________________________________________________________________________

Find your success! Subscribe to free Packaging Digest enewsletters.

Find your success! Subscribe to free Packaging Digest enewsletters.

____________________________________________________________________________________________

The technology’s capacity to incorporate other data forms and product tracking information continues to be paramount as technology pushes forward and the nature of anti-counterfeiting changes with the times. This enables holograms to be used for an expansive range of pharmaceutical authentication and brand protection roles, linking on-pack product identification with supply chain management, market enforcement and forensic support services.

In this way, the identity and distribution of goods can be controlled through a total system solution involving security authentication features, tracking mechanisms and investigative services.

Of notable value to the brand owner—and a strong financial incentive to make the investment in such systems—is the fact that the information generated at the labeling stage can be linked to the company’s enterprise resource planning (ERP) system; enabling business functions such as manufacturing, supply chain management, finance, projects, human resources and customer relationship management to be captured and better managed.

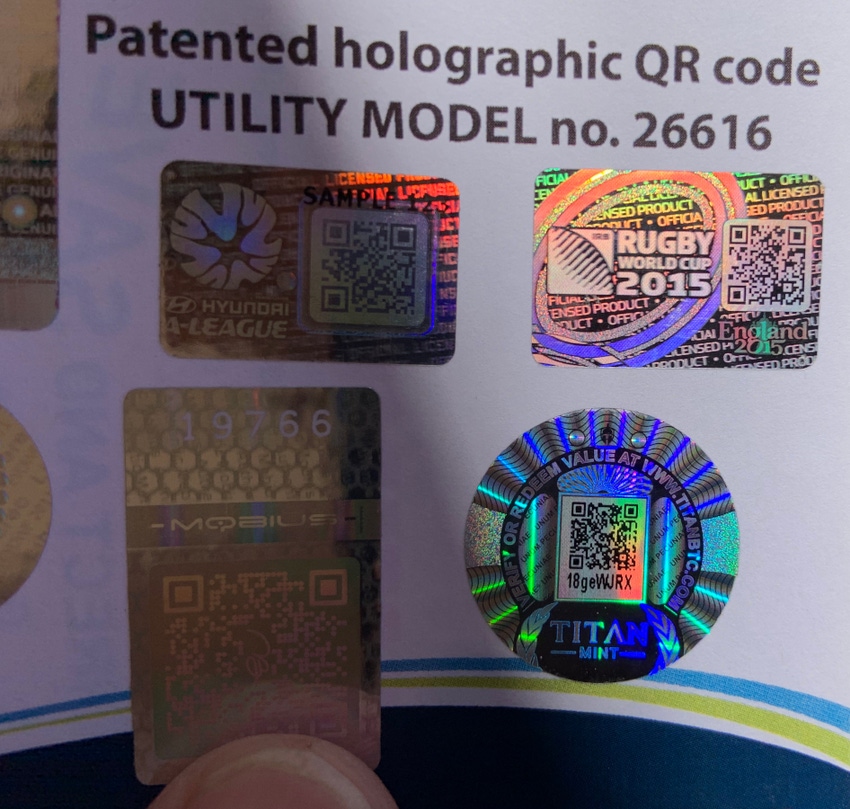

One example of an interesting development in the area of track-and-trace holography comes from U.S.-based Holoptica. The embossed hologram producer’s secure document verification and authentication product called DocVAULT that uses a new holographic feature called holoCOMPASS. The combination of holography with a holoQR (see image above) and holoCOMPASS is opening up new potential as an anti-counterfeit system for prescription and over-the-counter (OTC) pharmaceuticals, among other products. One application is for smart labels, specifically an Internet of Things label (IoT) that combines anti-counterfeit holographic and other technologies, such as near-field communication (NFC), with mobile authentication within a single product.

Integration

Continuing moves towards outsourcing the production of pharmaceutical and healthcare products might be beneficial in terms of reducing manufacturing costs, but it can also impact the control of brand security and visibility. Here, holography can be integrated into the supply chain security process to allow companies to maintain control of their products—from the sourcing of labels or proprietary components to the manufacturing and shipment of finished goods.

The technology can also be integrated with secure web interfaces to help eliminate rogue ordering of products while authorised distributors can pick, pack and ship items in carefully measured quantities to customers, with the product’s movements throughout the supply chain fully tracked and documented. And it is important to encourage brand owners to take the necessary steps to create awareness about holograms—and their multifarious applications and benefits—to fully unleash their potential.

About the Author(s)

You May Also Like