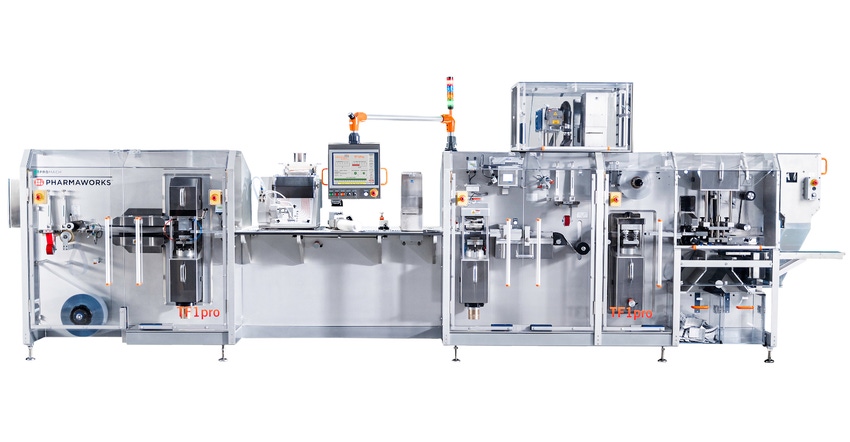

The TF1pro Blister offers a high level of versatility, product safety, and sanitation in a compact footprint to help pharmaceutical/biotech operations meet current Good Manufacturing Practices.

Pharmaworks new TF1pro Blister blister packaging machine is designed for pharmaceutical/ biotech manufacturers and contract packagers that frequently changeover products and package formats. It’s suitable for tablets, capsules, softgels, vials, syringes, liquids, and more. Fully servo-driven, it provides an easy-to-operate, highly versatile platform that achieves fast changeovers and ensures high accuracy.

“A large pharmaceutical customer asked us to develop a blister machine with the most advanced cGMP features,” says Ben Brower, Pharmaworks director of sales and marketing. “With its input, we developed the TF1pro — the only blister machine that offers this high level of product safety and sanitation in a compact footprint.”

Unusual on such a small system (21.85 feet long x 4.08 feet wide x 5.33 feet high), several sophisticated features ease cleaning and maximize safety. Sloped surfaces throughout eliminate the chance of cross-contamination from trapped product. Overload detection capability automatically stops the seal station if out-of-tolerance pressure is detected.

Being compatible with all corresponding materials, including polypropylene, its intermittent motion supports both thermoforming and cold forming applications. Reaching speeds up to 100 indexes (200 blisters) per minute and having a usable forming area of 120×165 millimeters with a depth of 25mm, the TF1pro can be configured to transfer blisters out its front, rear, or inline. If needed, optional vision inspection for product and printing is available, as well as full serialization.

Base material is handled via a specialized dolly to enhance sanitation, speed changeover, and improve operator ergonomics. It’s enclosed to protect it from particulate matter while on the machine.

By using sensors instead of pendulum rollers to handle the web, material drag and necking is eliminated, thereby saving material costs. A die-cut laser registration system aligns the index so materials are correctly placed and cut every time. Registration adjustment capability ensures that print on the material lines up perfectly. Ensuring consistent and accurate ejection, the reject/transfer station uses a vacuum arm to lift good blisters onto the outfeed conveyor, while bad blisters drop into the reject bin.

Designed for manufacturers and contract packagers running medium and small batches, such as clinical trials, the TF1pro has ergonomic, easy-to-use components that slide in and lock — including the guide track on the feeding station. Quick release covers on each station improve access. The heat area automatically retracts when not in use for operator safety and convenience during changeovers and maintenance.

An Allen-Bradley PLC controls machine functions. Being PC-based, the color touchscreen (up to 20 inches in size) presents a large and intuitive user interface to maximize operator ease of use.

Accommodating different feeders, accessories, and floor plans, the modular TF1pro is available with a variety of options. It was introduced during Pack Expo Connects 2020 in November.

About the Author(s)

You May Also Like