The role of packaging in navigating increasing industry competition

Over the last twenty years, demand for generic pharmaceuticals has tripled in the United States.[1] As patents for branded drugs expire and generics enter the market, the pharmaceutical industry has become an increasingly competitive marketplace, placing an ever-greater importance on efficiency and cost savings in the manufacturing process.

Patent protection on a drug in the United States usually lasts for 20 years, at which point the patent owner reaches the so called “patent cliff” – the date at which a drug patent expires and a significant drop in sales volume and revenue is, inevitably, soon to follow. Typically, as soon as a patent expires, a generic copy will enter the market, cutting the cost of the branded pharmaceutical by an average of 80-85 percent.[2]

While this practice generally has a negative impact on the total revenue of the pharmaceutical industry, it benefits patients by providing access to proven drugs at a lower cost. In fact, generics now make up 88 percent of U.S. prescriptions dispensed while only accounting for 28 percent of drug costs.[3]

Generic manufacturers enter the market at a much smaller profit margin than the branded drug they are replicating. As a consequence, generic manufacturers must maintain operations that are as lean as possible in order to turn a profit. For branded pharmaceutical companies, a higher margin is achieved throughout the life of a patent. The patent protection period for a branded drug begins on the date it is submitted to the United States Patent and Trademark Office (USPTO). However, the drug will still need to go through, roughly, a decade of clinical trials to test for efficacy and safety before it receives FDA approval. This process usually makes the effective patent period only 7 to 12 years.[4] On top of this, 95 percent of medicines fail during development, and only 20 percent recoup their research and development cost.[5] This makes it critical for the patent owner to operate as efficiently as possible during the timeframe they own the patent in order to earn back their investments.

Both branded and generic manufacturers then – as a result of the increased competition between them – have a vested interest in technologies that can improve efficiencies and cut costs in pharmaceutical manufacturing. The industry has focused on a number of new trends and technologies to do so – such as integrated machinery, flexible feeding technologies, nested filling solutions, and advances in packaging formats. Pharmaceutical professionals will be able to see these innovations and others at the co-located Pharma EXPO (McCormick Place, Chicago; November 6 - 9) and PACK EXPO International 2016. Pharma EXPO is co-produced by PMMI, The Association for Processing and Packaging Technologies and the International Society for Pharmaceutical Engineering (ISPE).

Packaging Innovation

Packaging innovation for the pharmaceutical industry is focused primarily on product safety, patient adherence and cost. “One of the main differences between pharmaceutical packaging and consumer packaged goods (CPG), is that purchasing decisions for prescription drugs are initiated by the doctor, not the consumer,” says Jerry Martin, Pharmaceutical and Life Sciences Consultant at PMMI. “Doctors are principally concerned with patient compliance and efficacy.”

Additionally, Anna Frolova-Levi, Vice President at Bilcare Research Inc., notes that even for over-the-counter (OTC) drugs – which account for 8 percent of U.S. pharmaceutical sales volume[6] – package convenience is not as important as drug safety and tamper evidence. “The authenticity of the drug is very important as well as the indicator that the package has not been tampered with,” Frolova-Levi explains. “In addition, with generics becoming the dominant drug category and competition peaking in the pharmaceutical market in general, cost containment will become a primary consideration for packaging.” Packaging innovations and changes in format that can reduce costs are, therefore, coveted in today’s pharmaceutical industry.

Many pharmaceutical manufacturers are looking to flexible packaging as one way to reduce costs, as the format can be lighter in weight and more compact than some rigid alternatives. In fact, pharmaceutical packaging is the fastest growing segment within the flexible packaging market, with a CAGR of 7.1 percent from 2013 to 2018.[7]

One recent innovation that can help pharmaceutical manufacturers take advantage of flexible formats is CHILD-GUARD by Presto Products Company (see image below). The solution is an enhanced version of a slider that has passed the testing protocol for child-resistance set by the Poison Prevention Packaging Act (PPPA). The innovation can be applied to a flexible pouch that can be used for bulk pharmaceuticals as well as serve as a novel variation on the traditional blister pack.

“This packaging format provides both generic and branded pharmaceutical manufacturers with the ability to utilize a flexible format – that can be attractive in terms of reducing costs – for the variety of pharmaceutical products in which regulations mandate child-resistance,” says Richard Custer, Commercial Director at Presto Products Specialty Division.

Integrated Machine Design and Flexible Feeding

According to Sabri Demirel, Sales Manager at Uhlmann Packaging Systems, the patent cliff has resulted in more interest in cost-competitive, lean machinery with a smaller footprint and faster changeover speeds. “Pharmaceutical companies, and generics in particular, are driven by cost,” notes Demirel. “As such, each side is looking to achieve higher margins through new efficiencies in their processing and packaging equipment.”

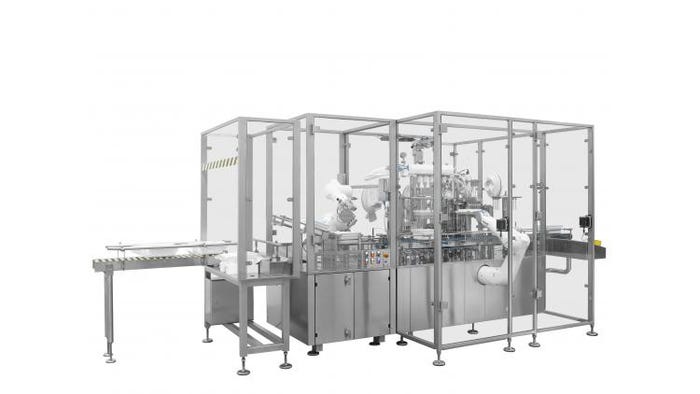

One of the best ways to improve efficiencies in this space is through integrated machine designs. Monoblock designs, where multiple units are integrated into one platform, can save space and maximize output. “In the past, manufacturers would need a machine, then a conveyor, then a machine, then a conveyor. The number of machines necessary would determine the length of the line,” Demirel explains. “Today, we have multiple machines that have been integrated into one platform. One of our more popular integrated machines – the IBC 120 – is, on average, 20 percent more efficient than solutions made up of separate components. ” (See image at top of page.)

Another central facet of improving efficiency relates to product changeover. “Some generic manufacturers offer hundreds of differently-shaped products,” Demirel says. “Flexible feeding technologies, which handle a broad range of products, can reduce the need to changeover each time a new product is run.”

Nested Filling Solutions

Randy Fraatz, Business Development Manager at MG America, notes that branded pharmaceutical manufacturers and generics alike are turning to an evolving trend that can improve efficiencies – nested commodity filling. Containers – such as vials, cartridges, and syringes – are delivered to the pharmaceutical manufacturer together in a nest or matrix, as opposed to the usual loose, bulk format. “The trend began with syringes, grew to include vials, and is now moving into cartridges,” Fraatz says.

Containers are delivered pre-sterilized from a supplier and ready-to-fill (RTF), eliminating the need for both a washing machine and a depyrogenation tunnel from the operations of the pharmaceutical manufacturer. “A nest of, for instance, 100 syringes are delivered in a RTF format,” explains Fraatz. “They can then be directly introduced into the filling and stoppering machine, where the syringes are both filled and a stopper is applied all while still in the nest. This system is an extremely efficient way of handling and filling containers.”

The process requires a new method to introduce nested containers, as filling machines have traditionally been designed to handle bulk or loose containers coming off a rotary table. “We have seen increasing industry investment in machinery and systems capable of handling nested commodities,” Fraatz says. “That has impacted where we focus our research and development and the types of machines we invest in from a design perspective.”

However, Fraatz notes that moving to a nested solution is a decision that must come as a result of a complex financial analysis involving multiple factors. Nested containers delivered in an RTF format are more expensive than bulk containers delivered in trays that still need to be cleaned. This cost must be weighed against the savings from removing the need for a washer and depyrogenation tunnel, including the floor space needed to operate each. Pharmaceutical manufacturers must also look at what drugs are in their portfolio, in their pipeline, and what type of processing flexibility they will require from their equipment. “Each project is truly unique,” Fraatz notes.

Above: The Steriline from MG America

Overcoming the Cliff

“There is a patent cliff every day,” Martin says. “And there will continue to be a patent cliff every day. That is the nature of the industry.” As the pharmaceutical environment becomes increasingly competitive, it is more important than ever for manufacturers to stay ahead of the curve and find the right solutions for their operation. Attendees of PACK EXPO International 2016 and Pharma EXPO will have an opportunity to see the latest solutions up close and in person. The shows also provide a forum for attendees to speak at length with suppliers in order to fully understand the pros and cons of different technologies.”

Together, the shows will feature more than 2,500 exhibitors and draw 50,000 attendees. To register for the events, visit www.packexpointernational.com or www.pharmaexpo.com. Attendees will have access to both shows with one badge.

Sean M. Riley serves as Editorial Director, Marketing & Communications, PMMI, The Association for Packaging and Processing Technologies, which represents the voice of more than 700 North American manufacturers of equipment, components and materials for processing and packaging. It works to advance a variety of industries by connecting consumer goods companies with manufacturing solutions through the PACK EXPO portfolio of trade shows, trade media, and a wide range of resources to empower our members. The PACK EXPO trade shows unite the world of processing and packaging to advance the industries they serve: PACK EXPO International, PACK EXPO Las Vegas, Pharma EXPO, PACK EXPO East, EXPO PACK México, EXPO PACK Guadalajara and ProFood Tech, launching in April 2017. Learn more at PACKEXPO.com and PMMI.org.

Exhibitor/Source Websites:

Bilcare Research Inc – www.bilcaresolutions.com

Presto Products Company – www.fresh-lock.com

Uhlmann Packaging Systems – www.uhlmann.de

MG America – www.mgamerica.com

References

[1] http://www.gphaonline.org/media/wysiwyg/GPhA2015AnnualReport.pdf

[2] http://www.fda.gov/downloads/Drugs/ResourcesForYou/Consumers/BuyingUsingMedicineSafely/UnderstandingGenericDrugs/UCM305908.pdf

[3] http://www.gphaonline.org/media/wysiwyg/GPhA2015AnnualReport.pdf

[4] http://www.news-medical.net/health/Drug-Patents-and-Generics.aspx

[5] http://blog.dicksondata.com/2015/12/drugs-losing-patent-protection/

[6] http://www.chpa.org/marketstats.aspx

[7] http://www.marketsandmarkets.com/PressReleases/flexible-packaging.asp

About the Author(s)

You May Also Like