March 11, 2015

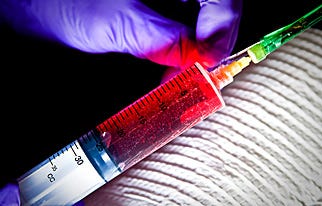

Syringe of Adriamycin

In a recent Harris Interactive survey of US physicians about the proper storage and handling of temperature-sensitive medicines prescribed and administered to patients, physicians reported being concerned about this issue, and the overwhelming majority are concerned that heat-damaged products resulting from cumulative exposure to temperatures outside the specified temperature range pose a health risk to patients. The announcement of the study findings was made today by Temptime Corporation.

“There may be complete loss of product efficacy, or loss of product potency – which can lead to interruptions in treatment protocol, serious adverse events, and/or failure to relieve patient symptoms. The impact can go beyond individual patients to the public health level, particularly when vaccines are involved.”

“Physicians have experienced cold chain breaks in clinical practice since we first began using medicines that required refrigeration,” said Donald T. Allegra, MD., FACP, who is not affiliated with the study. “Now, with advancements in science and medicine trending toward increased use of biologics, vaccines and other temperature-sensitive medicines, we need far more vigilance around the cold chain to protect life-saving medicines from temperature abuse, and protect our patients from associated risk stemming from undetected temperature abuse.”

The use of temperature-sensitive medicines such as vaccines, other protein based products, blood products, chemotherapeutic agents, to name a few – is growing worldwide.

The US remains the largest market for biotech products, and holds 56% of the global biologics market. Temperature-sensitive products must be managed with strict storage and handling processes to ensure they are maintained at specific temperatures throughout the cold chain -- a term used to describe the systems employed to maintain a specific temperature or temperature range throughout the manufacturing, packaging and distribution of temperature-sensitive products.

“When products requiring refrigeration are exposed to cumulative temperatures outside the specified zone (usually 2°to 8°C/36°to 46°F), several things can happen which negatively affect the products,” said Dr. Allegra. “There may be complete loss of product efficacy, or loss of product potency – which can lead to interruptions in treatment protocol, serious adverse events, and/or failure to relieve patient symptoms. The impact can go beyond individual patients to the public health level, particularly when vaccines are involved.”

According to the Harris Interactive research, three in five physicians are at least “very concerned” about ineffective treatment and/or no relief of patient symptoms. More than half of physicians across all specialties surveyed are concerned about potential serious adverse events related to heat-damaged products. Primary Care Physicians (PCPs) and pediatricians (the top prescribers of vaccines) are most concerned of all specialists surveyed about outbreaks of preventable disease caused by administration of heat-damaged vaccines.

About Cold Chain Breaks

Breaks can occur anywhere along the many touch-points after the manufacturer’s release through to administration to patients. The more complex the transportation process, the greater the likelihood of human, mechanical, or technical failure.

A key finding in the study is that breaks in the cold chain are commonplace, and most physicians have experienced a cold chain break in their clinical practice. More than 7 in 10 physicians across most specialties surveyed reported having experienced first-hand breaks in the cold chain in practice. 72% of specialists surveyed including endocrinologists, hematologists/oncologists, and rheumatologists experienced a cold chain break as compared with 83% of PCPs/pediatricians. Specialists reported more delivery-related breaks, which are thought to occur when products are in transit to physician offices. PCPs/pediatricians reported more storage-related cold chain breaks, occurring after the products arrive at the offices.

Physicians report a lack of confidence that heat-sensitive products were stored properly along the cold chain. Less than a third of physicians surveyed (30% of PCPs/Pediatricians and 21% of Specialists) reported being “very confident” in the temperature management of these products.

About Current Technologies

More than 15 countries worldwide use cumulative heat monitoring devices affixed to each unit of medicine to safeguard temperature-sensitive products and insure that heat damage can be easily identified before patient administration.

In the US, however, these individual time temperature indicators are not commonly used. More than 4 out of 5 physicians (89% of pediatricians and 87% of specialists) agree they would be interested in a device that monitors the temperature of individual product units to the end user.

The pharmaceutical industry uses stability data from both accelerated and long-term studies to establish recommended storage conditions and expiration dating for products. As long as a product remains in its approved container within the specified temperature range, the quality of the product is assured until the date of expiration.

However, it is likely that a product will be exposed to temperature outside of its specified storage range as it passes through the distribution chain from the manufacturer to the end user. When heat damage occurs, the integrity of the product declines and the risk to patients increases.

SOURCE: Temptime Corporation

Photo by brianjmatis

.

.

About the Author(s)

You May Also Like