Unwrapping 2024 Manufacturing Trends

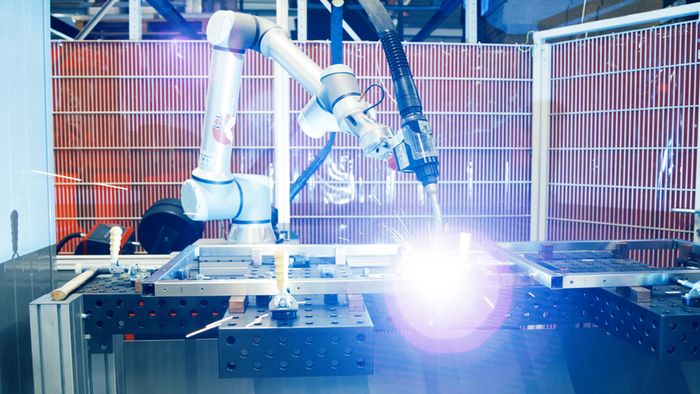

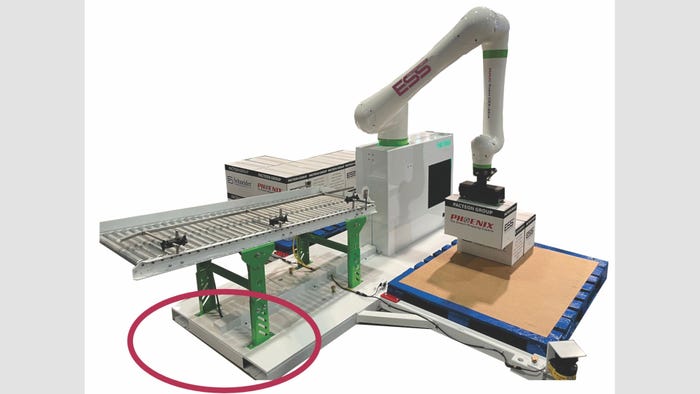

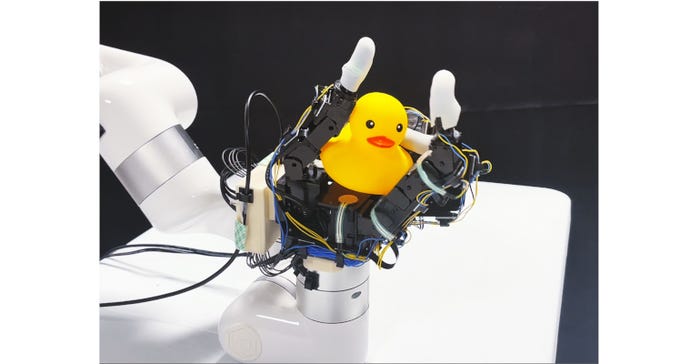

Automation

6 Packaging and Manufacturing Trends Unwrapped6 Packaging and Manufacturing Trends Unwrapped

As we continue through 2024, the packaging and manufacturing industries are poised for significant transformations driven by automation.

Sign up for the Packaging Digest News & Insights newsletter.