It's a new era at Bissell Homecare Inc. An upgradedpackaging line runs the company's new concentrated carpet-cleaning productsthat are packaged in new containers. And it all takes place on the same site asBissell's new Innovation Center.

Since 1876, Bissell has been a world leader in manufacturingand marketing a broad line of quality home and floor care products—sweepers,deep cleaning machines, vacuums and cleaning formulas. The company is bestknown for its line of mechanical carpet cleaners, which predate electricalvacuums by 50 years and continue to defy obsolescence. In the process, Bissellhas pulled ahead of Hoover to take the number one spot in North America forfloor-care sales.

In 2008, Bissell spent more than $9 million to renovate anexisting factory in Walker, MI outside of Grand Rapids into its spectacular newBissell Innovation Center, simultaneously making upgrades to it. Bissellrenovated more than 35,000 sq ft of existing space, constructed nearly 5,000 sqft of new space and completed a 5,000 sq-ft- patio.

New construction began Octover 2009 and was competed August2009. The entire renovation was a two year project.

New bottles have many advantages

The company also upgraded a packaging line on the site torun its new concentrated carpet-cleaning solutions in seven bottle sizesranging from eight- to 60 fl oz. The cleaners are twice as concentrated as thesolutions they replace. Bissell worked with creative agency Product Ventures toredesign the previous packaging.

This included the bottles, caps and labels. Product Venturescreated structural packaging for the new line of 2X concentrated formula, aswell as incorporating optimized ergonomics and dispensing features, to improvethe overall consumer experience. The new formulas and the nearly half-sizebottles provide the same cleaning power in half the packaging of thenon-concentrated formulas, which ultimately reduce the burden of plastic on theenvironment.

These new smaller bottles use less shelf space and make iteasier for consumers to carry, store and pour the products. This new design,with a built-in measuring cap, creates a simpler, greener way to cleandeep-down dirt in carpet and upholstery.

Like all Bissell deep cleaning formulas, 2X concentratedproducts carry the EPA's Design for the Environment (DfE) certification, whichis recognized for safer chemistry. By partnering with the DfE program, Bissellis taking part in a national effort to improve the human health andenvironmental profile of chemical-based products.

You can read about this in more detail in the November 2009issue of Packaging Digest, page 6.

Net-weight filling

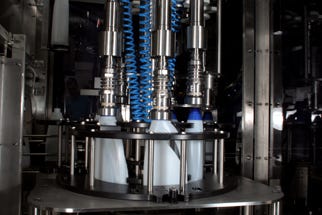

Bissell forms its own HDPE bottles, which it stores in largebins. During PD's visit, the line was running the 60-oz bottle. To start theoperation, workers manually place the rectangular bottles on the packagingline. A Videojet Excel inkjet printer from Videojet Technologies Inc. appliesthe lot code and production date to the bottom of the bottles as they are conveyedto a 16-head net weight, gravity filler from Serac Inc. A feedscrew at theinlet of the filler meters the bottles into a starwheel that, in turn, placesthe bottles onto the 16 individual platforms of the filler. Because of theoff-center necks of the bottles, the starwheel maintains very precisepositioning on the filler platforms to ensure that the open tops are beneaththe fill nozzles.

To achieve the filler's extreme accuracy, each platformincorporates a loadcell that weighs the bottle as it enters the machine, afterwhich the industrial-PC controller opens the fill valve. When the weightreaches the set weight of product, it closes the valve. In addition to handlingthese netweight calculation for each bottle, the control system on the filler recordsprocessing and filling data for every bottle run and provides statisticalproduction feedback.

For example, it will monitor run times, present astatistical fill-weight average and standard deviation for any period ofproduction selected, monitor the tare weight of incoming bottles and alert theoperator if a bottle is outside of the acceptable range, and list the number ofunder- and over-fills with the cause of each. When changing from one bottle toanother, the operator only has to select the new bottle from the menu in thecomputer, and the PC will set fill and operating parameters automatically.

Rotary capper

Bottles leave the filler through a starwheel and travel to afive-head rotary capper from Fowler Products Co. LLC. Bottles are metered intothe continuous-motion capper through a feed screw and then travel around a starwheel onto label plates on a center platform, which transports them around thecapper. The caps are loaded into a floor hopper and carried up to the overheadcap hopper by a cleated elevator.

Bissell

The caps drop into a rotary sorter that orients them in anopen-side down configuration and delivers them into the cap track, where theytravel down into the capper. Because these tapered measuring caps have a heightlarger than their diameter and tend to nest, Bissell is using Fowler'sUniversal Series sorter, in which the caps fall into pockets in a rotatingdisk.

The pockets pass over a selection area where caps that arein the pockets with their open side facing up are ejected back into the bowl.Caps that are properly oriented discharge into the cap chute that transportsthem down into the capper.

The caps are picked up by a rotating cap-transfer starwheel.This unit rotates and presents the cap to the chuck in the capping head, whichgrips the cap and descends onto the bottle. The Bissell caps have smoothtapered sides and tend to drop out of the chucks, so the chucks at Bissell usevacuum instead of mechanical grippers to hold the caps in place.

After the cap is placed on the bottle, the vacuum isreleased, and the chuck turns until it reaches the set torque, at which time itreleases the cap. If a bottle-pocket in the capper does not contain a bottle,the unit does not release a cap.

The same-size tapered measuring cap is applied to all sizesof bottles that don't use spray caps. The measuring caps are produced by GemPlastics.

Caps are retorqued

Bottles discharge through a starwheel and are conveyed to aninline capper from Kaps-All Packaging Systems that was installed to run bottleswith flat caps, which the plant occasionally runs on this line. The cappedbottles pass through an induction sealer from Pillar Technologies, an ITW Co.

The bottles then travel through an inline ACT-8 automaticeight-spindle capper from Accutek Packaging Equipment Co. Inc. that is used toretorque the caps after the induction sealer to ensure tightness. Each of theeight tightening spindles can be adjusted on the fly to ensure maximum torqueaccuracy, decreasing disk wear and closure scuffing, and allowing the machinesto adapt to a variety of containers types, sizes, and shapes.

Next the bottles pass through an inspection system fromTeledyne Taptone that checks each container for leaks. The unit is suspendedover the conveyor and as each container passes through the unit, belts on bothsides of the conveyor compress the head space of the container. A sensor takesa measurement at the discharge of the unit and if the measurement is outside ofthe acceptable range, the bottle is rejected.

Shrink-sleeve label on cap

From the inspection system, the bottles are conveyed to aModel 35pw p-s labeler from Accraply, a div of Barry-Wehmiller Companies Inc.that applies front and back labels. The unit features a variable speed conveyorto accommodate different size bottles with servo-driven speed-following labelheads, all accessed by the touch-screen HMI. An air-assisted, contour-followinglabel peeling system optimizes label wiping on the rectangular bottles.Operating parameters are stored in the unit's memory and can be recalled at atouch.

Next, the bottles travel to an Axon LLC shrink-sleeveapplicator that applies a clear shrink-sleeve label over the cap. The film ispulled from a roll, passes through a motorized film unwind system and is pulledover the top of the machine and down into the application chamber.

It passes through a series of guide rollers and is thenpulled over the bullet, where suction cups pull open the tubular film. In thisoperation, two stepper-driven rollers work in conjunction with theprint-registration system to ensure that the correct length of film isadvanced.

The print-registration system, which utilizes Smarteyephotoelectric sensors from Tri-Tronics Co., is located at the top of the filmmandrel and includes both vertical and horizontal adjustments. When thephotoeye senses the container, the vacuum is released from the suction cups,and a plunger pushes the film onto the container. Once the product has clearedthe application area, a new label is dispensed through the pullroll assembly.

This label is then held in place by a set of suction cups,where it is cut using a guillotine-style blade. Once the film has been cut, thegripper arms return to the their home positions opening the film for the nextproduct.

The bottles are conveyed through an Axon steam tunnel thatshrinks the film around the cap. During the shrink process, the lower edge ofthe film actually shrinks around the bottom of the cap.

The bottles then travel past a Label-Aire Inc.pressure-sensitive spot labeler that applies small spot labels for specificoccasions. This unit was not running during PD's visit.

Servo-driven case packer

Next, the bottles are conveyed to a case packer from HamrickManufacturing & Service Inc. The bottles enter the unit single file and areseparated into multiple lanes by a servo-controlled lane divider that helpsachieve consistent lane accumulation and prevents lane jams. Bissell was splittingthe 60-oz bottles into three lanes, although the machine can run up to sixlanes, depending on the bottle size and configuration.

The D designation in the model number indicates that this isone of Hamrick's most advanced case packers that incorporates an onboardservo-controlled lane divider. Machine control is derived from an internalsoftware-based sequencer and the lane divider and case packing are underconstant control from a PLC with a preprogrammed selector switch andprogramming pad.

Other features of the machine include a high-speed,surge-controlled container conveyor that automatically adjusts its speed tofill the lanes, speeding up and slowing down as needed, and variable-speedcontainer and case conveyors with the speeds set automatically by the computer.

Product changeover is expedited with up to 20 separate setsof timing values that are in the PLC and up to 255 unique lane positions in theservo-controlled divider. Operating parameters for every container aremaintained in memory and can be selected by the operator through the HMI.

The corrugated cases are erected by a machine from SouthernPackaging Machinery Inc. and enter the Hamrick case packer traveling in thesame direction as the bottles, which are on the conveyor above them. The packerloads two cases at a time, so it releases two cases from the backup and aflight bar pushes them into the loading zone.

Simultaneously, the machine releases enough bottles to fillthe two cases and they also travel into the drop zone and are held back by agate. Once both the cases and bottles are in the proper positions, a plateopens beneath the bottles and they drop into the case. The case is lifted andhas just started back down as the bottles are released, thus cushioning theimpact of the drop.

Cases then travelthrough a top taper from Highlight Industries that features adjustable sidebelt drives that automatically fold the flaps and provide accurate, consistenttape application. The taper is followed by inkjet units that print date and lotcodes on the cases. These include a unit with ProSeries print heads fromFoxjet, an ITW Co. and an Anser™ unit from Inkjet Inc.

The cases are palletized by a floor-level palletizer fromLambert Material Handling. The pallets are then stretch wrapped by a Freedom6500 rotating arm machine from Highlight Industries, which applies film underthe edge of the pallet for increased stability.

Bissell has standardized on controls throughout the line andhas installed integrated controls to maintain smooth operation. Thus, theconveyors on the line feature 24-in. zoned accumulation sections that will stopand start as bottles back up. The machines on the line communicate with eachother and sensors located along the line sense bottle backups and adjust the speedsof the individual pieces of equipment accordingly.

Accraply, a division of Barry-Wehmiller Companies Inc.,

800/328-3997. www.accraply.com

Accutek Packaging Equipment Co., Inc., 760/734-4177.

www.accutekpackaging.com

Axon LLC, 800/598-8601. www.axoncorp.com

Fowler Products Co., LLC, 877/549-3301.

www.fowlerproducts.com

Foxjet, an ITW Co., 800-369-5384. www.foxjet.com

Gem Plastics, 616/538-5966

Hamrick Mfg & Services Inc., 800/321-9590.

www.hamrickmfg.com

Highlight Industries, 616/531-2464.

www.highlightindustries.com

Inkjet Inc., 800/280-3245. www.inkjetinc.net

Kaps-All Packaging Systems, 631/727-0300. www.kapsall.com

Label-Aire, Inc., 714/449-5155. www.label-aire.com

Lambert Material Handling, 800/253-5103.

www.lambertpalletizers.com

Pillar Technologies, an ITW Co.,

888/745-5276. www.pillartech.com

Product Ventures LTD, 203/319.1119

www.productventures.com

Rockwell Automation, 414/382-2000.

www.rockwellautomation.com

Serac Inc., 630/510-9343. www.serac-group.com

Southern Packaging Machinery Inc.,

770/822-0007. www.southernpackaging.com

Teledyne Taptone, 508/563-1000. www.taptone.com

Tri-Tronics, 800/237-0946. www.ttco.com

Videojet Technologies Inc.,

800/843-3610. www.videojet.com

About the Author(s)

You May Also Like