Custom Blending, Ft. Collins, CO, provides spices, flavors and proprietary blends to foodservice distributors, manufacturers, retailers and restaurants around the globe. Products include extracts, flavors, emulsions, vanilla products and liquid colors. In addition, the

1 - rrrrFiller.jpg

company is a private label producer and also produces items under its own label.

According to the company, its consumer product line, Rodelle, which is found in grocery stores throughout North America, is America's fastest growing brand of vanilla extracts and baking essentials. Its recently introduced health and wellness brand, Harmony Valley, gives health-conscious chefs and dieticians endless vegetarian options.

New plant

Custom Blending recently opened a new plant with two liquid packaging lines and one powder line. Its newest liquid line runs a range of plastic and glass bottles ranging in size from 2 oz to 1 gal at speeds up to 80 bottles/min.

Custom Blending selected Inline Filling Systems (IFS) as the systems integrator for the new line and it supplied much of the equipment on the line, including the bottle unscrambler turntable, filler, capper and conveyors. "Inline Filling helped us a lot," says Custom Blending's production manager James Calliham. "We run a lot of different products and bottles, and our success is based on versatility and offerings to our customers. Inline really listened to what we wanted."

To start the packaging operation, workers manually place empty bottles, which are primarily supplied by *TricorBraun, from a pallet onto an IFS Valueline unscrambler turntable that feeds the bottles single file onto the infeed conveyor. The speed of the variable speed unit can be adjusted from zero to seven rpm (82.5 feet/min) depending on the size of the bottle being run. The turntable includes a square bottle orienter that consists of a motorized round disk turning counter-clockwise to the rotation of the turntable to orient square bottles for smooth feeding onto the conveyor.

Filler uses multiple nozzles

The bottles are conveyed to Model

5 - rrrrinduction sealer.jpg

FOFNT60 automatic inline overflow filler that is equipped with up to 14 fill nozzles. The actual number of nozzles used during production ranges from 14 nozzles for the 2-oz bottles to six nozzles for gallons. This is an intermittent machine, so the bottles are stopped during the fill cycle.

Bottles are admitted into the filler in groupings that coincide with the number of nozzles in use. Thus, when running gallons, six bottles would be admitted at a time. The conveyor running through the machine runs continuously, so a gate holds bottles back at the entrance to the filler and then retracts to admit the correct number. Another gate holds the bottles in place beneath the fill nozzles as they are filled.

With this overflow filler, product is pumped continuously to the fill nozzles. When it reaches the fill level in the bottle, the overflow recirculates back to the product supply tank. This recirculation feature makes overflow fillers a good choice for foamy products, because the closed system permits re-circulation of foam into the product supply tank, although the system is suitable for a range of products including sauces, syrups, light gels and shampoos, foamy cleansers and chemicals, water and other non-carbonated water-thin beverages.

Product at Custom Blending is pumped from the processing tank to the product supply tank that supplies the filler. From there, a diaphragm pump delivers the product to the fill nozzles. The overflow product is recirculated back to the supply tank.

The filler at Custom Blending is equipped with Inline's multistage fill system. This is a programmable three-stage filling cycle (fast/slow/dwell) that enables the operator to optimize pump speed at each stage of the filling operation. Thus, he could start out filling rapidly, slow down at the finish and then momentarily stop the fill completely. The cycle is different for each product and bottle size.

The nozzles for the small glass bottles are specially designed with a vacuum breaker feature that admits air into the bottles when filling is completed. This allows easier removal of the nozzles from the containers.

The machine is equipped with a touchscreen control panel with a PLC that stores up to 50 filling-cycle setup parameters for instant recall. A batch bottle counter records the number of filling cycles completed, and the machine will stop if a bottle is missing in the fill zone or there is a downstream backup. A starwheel indexing system allows for container stabilization and positioning at higher speeds.

Bottles leaving the filler travel beneath an UltraDoser-FD liquid nitrogen injectio

2- rrrrLiquid Nitrogen .jpg

n system from Chart Inc. that deposits a small amount of liquid nitrogen into each bottle as it passes beneath the injection head. Once the liquid nitrogen (which is at -320 deg F) is introduced into the container, it immediately picks up heat and turns into gaseous nitrogen, expanding 700 times in the process, and essentially flushing out any oxygen. When trapped inside the container, the gaseous nitrogen creates pressure and adds rigidity to the container.

In this operation, a sensor detects the speed of the line and a second sensor detects the presence of a container. The dosing head then opens and dispenses an exact amount of liquid nitrogen-typically about a drop. A dedicated PLC integrates and controls the sensors, controls and human interface.

The bottles then travel through a double-belt bottle spacer from IFS that consists of two opposing belts running parallel to the conveyor that separate the bottles so they can pass through a Model IQ2 metal detector from Loma Systems. The detector features a full color graphical touchscreen control panel with icon-driven menus. IFS supplied a conveyor with a metal free zone specifically designed for integration with the metal detector. The conveyor allows the conveyor chain to transit through the metal detect zone.

A variable-speed bottle spacing wheel from IFS mounted on the conveyor after the metal detector creates spacing between containers entering the capper. The unit, which consists of a motorized horizontal disk running parallel to the continuously running conveyor, momentarily halts forward movement of the container on the conveyor.

Capper uses parallel belts

The bottles then enter the IFS Computorque NT automatic inline capping machine that applies and torques caps onto containers as they pass through the machine. The unit features Inline's patented ca

4b-rrrrcapper.jpg

p tightening system, which uses parallel belts traveling in opposite directions that tighten the caps onto the bottles. Pistons pulse the belts at adjustable frequencies and amplitudes to achieve the required cap torque. The capper control panel visually displays operating parameters and messages for concise operator feedback and maintains the settings in memory for easy recall.

4a - rrrrcapper overview.jpg

Caps for the bottles are loaded into a floor level cap bin and delivered up to the overhead centrifugal sorter by an elevator/feeder. A spinning disk in the sorter moves the caps to its outer periphery where an air jet blows caps that are oriented with their open side up back to the center of the disk for resorting. Properly oriented caps are sent down a track and into a powered belt for final orientation.

The caps travel under a hook. Caps that are properly oriented with the open side down are unaffected and transfer to an inclined cap chute and are carried to the capping machine pick-off. Caps that are oriented with their open side up are caught by the hook and flipped back into the sorter.

Bottles leaving the capper, pass through an Enercon Industries Corp. Super Seal 100 induction sealing system that heats and applies a foil/laminate tamper-evident seal to the tops of the plastic bottles. An air-cooling system eliminates the need for a water recirculator, saving floor space and money.

The bottles then enter a bottom-code transfer device from IFS that uses parallel belts to grip the sides of the containers and transport them over a gap in the conveyor so that a bottom code can be applied. This is accomplished by a Model 3120 carbon dioxide laser marking system from Videojet Technologies Inc.

This unit can apply complex multi-line alphanumeric information, foreign-language character sets, graphics and machine-readable codes to a range of materials. Information-such as expiry and manufacturing dates, document numbers, system codes, ID matrix and bar codes, sequential numbers, batch codes and numbers, and even information about contents and weight-is processed quickly and easily by the laser coding system.

Front/back and wrap labeler

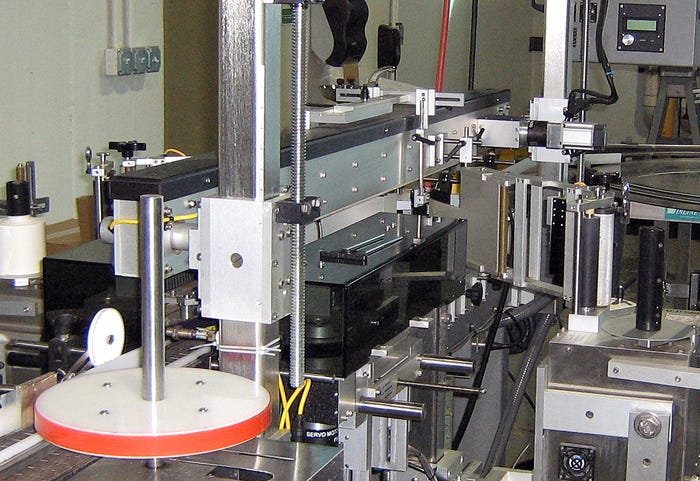

The bo

6- rrrrlabeler.jpg

ttles are then conveyed to a Universal Labeling Systems Inc. Model CP-1000 labeler. To start the process, parallel servo-driven belts meter bottles into the unit to achieve proper spacing for label placement. Stepper driven units then apply the labels. The entire unit is synchronized so one adjustment sets every operation on the machine from the bottle infeed metering to the overhead hold-down belt to the label application.

One of the major label suppliers at Custom Blending is WS Packaging Group Inc.

Finished bottles are accumulated on a turntable at the end of the line and are transferred to a pack-on/off table for hand packing, both of which were supplied by IFS. The table is cut to match the curve of the turntable for ease of transfer.

Controls for the entire line were developed by IFS. Machines are turned on and off independently, but sensors along the line actuate machines as required. For example, if bottles back up after the filler, the system will turn off the filler until the backup ends, at which point, it will turn it back on.

Inline Filling Systems Inc., 941-486-8800, www.fillers.com

Chart Inc., 800-371-3303, www.chartdosers.com

Enercon Industries Corp., 262-255-6070, www.enerconind.com

Loma Systems, 800-872-5662, www.loma.com

TricorBraun, 800-325-7782, www.Tricorbraun.com

Universal Labeling Systems Inc., 877-236-0266, www.universal1.com

Videojet Technologies Inc., 800-843-3610, www.videojet.com

WS Packaging Group Inc., 877-977-5177, www.wspackaging.com

About the Author(s)

You May Also Like