January 30, 2014

|

Hewlett-Packard (HP), Palo Alto, CA, took the retail packaging of its notebook computers out of the box and won Wal-Mart's Home Entertainment Design Challenge, which is a contest that encourages consumer product companies to further reduce the environmental impact of products in the home-entertainment category. HP took one of the products that already was selling with the world's largest retailer—an HP Pavilion dv6929 entertainment notebook computer—and replaced the box used for retail shelf packaging with the HP Protect Messenger Bag.

The move reduced product packaging by 97 percent, which conserves fuel and reduces carbon dioxide emissions by removing the equivalent of one out of every four trucks previously needed to deliver the notebooks to the retailer. The more efficient packaging design allows HP to fit 31-percent more products on each pallet delivered to Wal-Mart and Sam's Club locations.

|

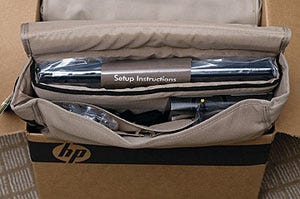

Above, a bag is readied fo HP's 10-drop series qualification. The HP Project Messenger bag, below is designed to protect without the use of not only the display box for the retail shelves, but also the multiple boxes often used to hold the accessories. |

|

Opportunity beckons

The idea of replacing disposable retail shelf packaging with a reusable accessory had been one that HP packaging engineering program manager Randy Boeller had been bouncing off of his peers in Houston, TX ,for a while. When HP was presented with the challenge, Boeller was eager to share his idea with the team, despite the project's compressed schedule.

Boeller knew that his idea had an achievable goal, if he leveraged a long-standing relationship with Glen Morroni, senior project director at Uneka Concepts (www.uneka.com). “I knew a guy there who would jump through hoops and make stuff happen fast,” Boeller recalls.

Wal-Mart used three criteria to evaluate the submissions: great design that attracts consumers; product innovation that reduces the environmental impact for that product category; and packaging design that facilitates reuse and recycling, reduces waste; and reduces or eliminates toxins.

Sustainable yarn

“The messenger bag is made out of fabric that is produced from recycled soda bottles and water bottles,” says Boeller. The fabric is woven from Repreve yarn, which is manufactured by Unifi, Inc. (www.repreve.com).

The company uses a proprietary process that produces a soft and comfortable yarn, which Unifi says is different from the results from earlier industry attempts that resulted in lower-quality yarns. Unifi also says that 50,000 BTUs are conserved for every pound of Repreve polyester yarn used.

This recycling technology doesn't come cheaply though. “It [manufacturing with Repreve yarn] certainly wasn't done for price,” says Boeller. “It was not the lowest cost option.”

Six is enough

In addition to efforts made to give the bag high-quality tactile properties, HP paid a lot of attention to the messenger bag's design, which features a hip, fresh graphic element in addition to the HP logo. Six colors, including black, were used to screen-print the bag for extra pop.

While it's important to have a bag that is attractive, it doesn't do consumers any good if the packaging cannot protect the product.

Drop, shake, roll

|

When HP and Uneka Concepts were designing the bag, they did so with the knowledge and understanding that the product and the bag would have to pass HP's drop-test requirements.

As prototypes came in and out of HP's testing lab, they were dropped from heights exceeding 2 ft, and then put into an overpack three at a time. The overpack box with the three bags and their computers inside were dropped again, then given a good shake.

The 10-drop series qualification was done using a Lansmont (www.lansmont.com) PDT drop tester. The testing series includes a bottom-corner drop, three edge drops and drops on all flat faces of the bag, and is conducted at the height of either 30 or 36 in., depending upon the total weight of the bag, unit and accessories.

The computer then is taken out of the box and visually evaluated, powered up and put through a functional test. This is completed with specially designed software.

After some modifications and retesting, HP finally was satisfied with retail packaging that included the messenger bag and a small amount of PE foam on the two sides to protect the product inside.

Using the bags that passed the initial drop testing, HP then packed three of these bags into the cardboard overpack that would be used to ship the computers to a store. This overpack would be removed at the retailer before the computers are placed on the store shelves, so the consumer would not see, receive or be obliged to dispose or recycle the box.

The overpack, then, is subjected to a 30-in. drop using the same drop-series parameters as those conducted on the individual messenger bags.

The vibration testing was conducted using an electromagnetic vibration table from Ling Electronics (www.qualmark.com). The test series included both random vibration and sweep-and-dwell vibration. The random vibration used a truck-and-air profile in accordance to the American Society for Testing and Materials Method ASTM D4728.

A sweep-and-dwell vibration test, as Boeller explains, is when an engineer instruments a unit and sweeps it through a given frequency range to identify the harmonic resonance in the package and dwells at the frequency for a set time.

Remove it, but prove it

“It's easy to say, yeah, we're being green by using less packaging,” says Lansmont Corp. marketing and business development manager Eric Joneson. He goes on to say that consumer goods companies can find themselves in very tough situations if the alternative or down-gauged packaging fails. The profits made from the move to “go green” can end up going toward a completely different type of green—dollars.

Emphasizing that he is not taking an anti-sustainability packaging stance, he comments: “I'm not saying don't do it. Actually, I'm saying do more. Take that last step to verify that you truly have a good solution.”

When HP tested its packaging, the company made sure that its out-of-the-box thinking wouldn't leave consumers with defective computers. Joneson calls this “dotting your i's and crossing your t's.”

To take that extra step, Joneson shares a formula for product-and-packaging performance during transit: product + packaging = distribution environment. “All those things, the durability of the product plus a protective performance of a package must equal or exceed the environmental hazard present within the distribution environment,” says Joneson. “So if you use less packaging and the environment that you are shipping within doesn't change, then you better darn well make sure your product is more durable because something's going to give.”

Joneson believes the trend towards using alternative or less packaging might ultimately help end-consumers. “If sustainability is an opportunity to make improvements in product durability, that's a good thing,” he remarks.

Eye towards the future

As of presstime, HP plans to sell 15,500 HP Pavilion dv6929 entertainment notebook computers in this new packaging. These limited-edition computer-and-bag combinations will be available at Wal-Mart and Sam's Club locations exclusively. The packaging concept, though, is something HP is exploring across product lines.

More information is available: |

Intl Safe Transit Association, 517/333-3437. www.ista.org. |

Lansmont Corp., 800/526-7666. www.lansmont.com. |

Ling Electronics, a Qualmark Co., 888/425-8669. www.qualmark.com. |

Uneka Concepts, 925/251-1800. www.uneka.com. |

Unifi, Inc., 336/294-4410. www.repreve.com. |

About the Author(s)

You May Also Like