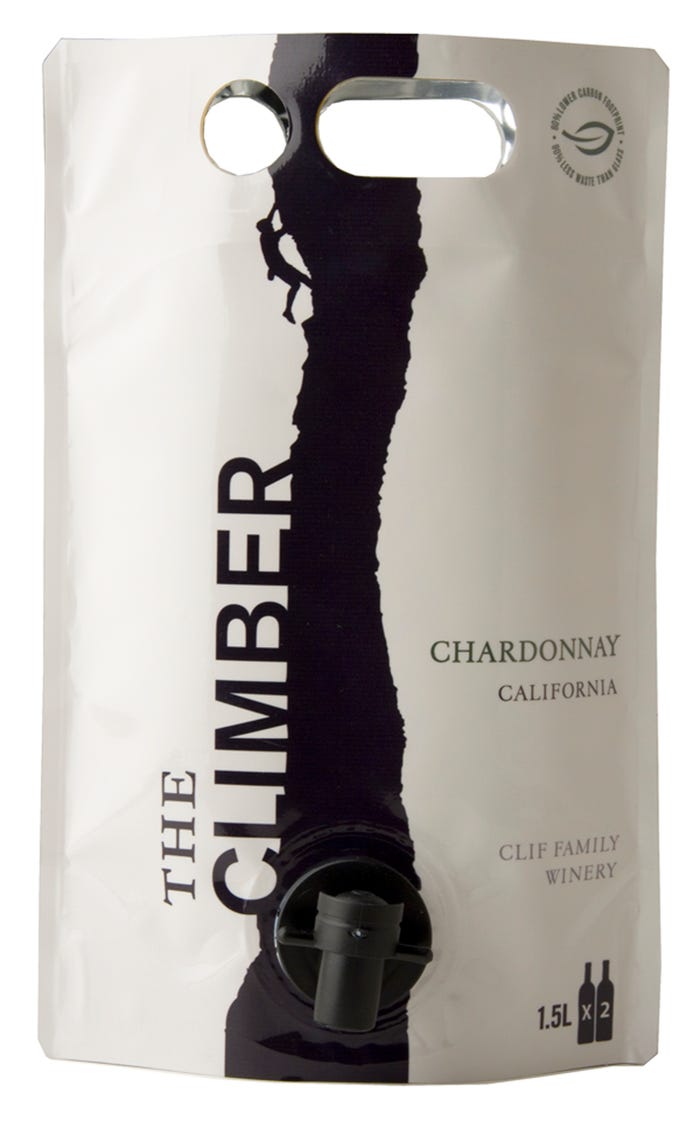

Wine in a pouch is one more move by the wine industry into more environmentally friendly and convenient packaging. Clif Family Winery, St. Helena, CA, has introduced the Climber Pouch, a 1.5L pouch of wine that contains the equivalent of two 750mL bottles and is designe

rrrbeauty.jpg

d for the outdoors.

The Climber Pouch, which is supplied by AstraPouch, features a dispensing spout and will stay fresh for up to a month in a cooler. According to AstraPouch, the pouch, which is double-gusseted to optimize shelf presence, is made of a laminate consisting of (inside to outside) PE metalized polyester (for oxygen protection) and reverse-printed clear PET.

Clif Family Winery owner Gary Erickson says, "The Climber Pou

rrrFiller.jpg

ch is affectionately known as the ‘all-terrain wine transport' around here. A day spent out on the hiking or bike trail that ends with friends, food and wine is our idea of a perfect day. The portability and flexibility of the Climber Pouch lets outdoor enthusiasts of all types wind down their adventures with the pleasure of great wine." The pouches, which include Chardonnay and Cabernet Sauvignon, sell for $16.99.

The Climber Pouch is filled at enoFILL, Sonoma, CA, a contract wine bottling and alternative packaging operation that began operations at Carneros Vintners in 2010. Jim Collins, owner of enoFill, says, "We provide an option for entrepreneurs who are looking for alternative wine packaging. We started with a wine bottling line, and we are running some unique bottles for our customers. Clif Family contacted us in 2010, and we installed two model Astrofill 4000 semi-automatic filling machines from AstraPouch to run the Climber Pouches." The machines are manufactured for AstraPouch by Torr Industries.

Plus/minus 0.5g fill accuracy

Each pouch machine has an operator

process.jpg

who initiates the filling operation by inserting the spout on the pouch into the jaws of the machine.

gluer.jpg

The machine removes the cap and fills the product. At the end of the fill cycle, the machine injects nitrogen into the pouch to remove 99 percent of the trace oxygen and "puff" the pouch for drip-free recapping. It then reapplies the cap and discharges the pouch onto a conveyor.

The machine features a touchscreen HMI that enables the operator to automatically select operating parameters from a menu, and the fill quantity is regulated by a turbine meter that achieves +/-0.5 percent accuracy. Wine is delivered to the fillers from specially-designed feed tanks by pressurized gas to minimize oxygen pickup.

Filled pouches are manually placed into a corrugated shipper that is divided into three zones by an insert. Three layers of pouches are placed horizontally into the zones, after which the shippers are conveyed to a Wexxar Packaging Inc. Bel 270 top-and-bottom gluer equipped with a Nordson Corp. Vista hot melt system. Shippers travel past a Model 5000 Markem-Imaje inkjet printer that applies a date and lot code, after which they are manually palletized.

AstraPouch. 585-259-9202. www.astrapouch-na.com

Markem-Imaje, 866-263-4644. www.markem-imaje.com

Nordson Corp., 770-497-3700. www.nordson.com

Torr Industries. 530-247-6909. www.torrind.com

Wexxar Packaging Inc., 604-930-9300. www.wexxar.com

About the Author(s)

You May Also Like