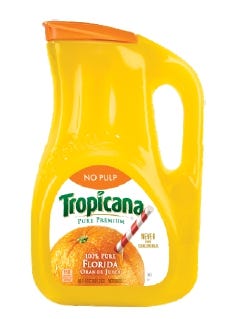

Tropicana multi-serve bottle

PepsiCo has replaced its white opaque jug with a new clear container for its multi-serve Tropicana Pure Premium orange juice. Holding 89 ounces of juice, the extrusion blow molded handleware bottle is easy to pour, easy to open with a new flip-top cap—and fully compatible with the current PET recycling infrastructure.

Edward Socci, Ph.D., director of advanced research at PepsiCo, unveiled the Tropicana multi-serve PET container to the audience at Packaging Digest's first annual Innovations in Food & Beverage Packaging conference, held April 18-19, 2012, in Rosemont, IL.

Socci, who was personally involved in the project, shared these remarks:

"We've worked at length to develop this container. You might have seen other containers in the marketplace long before ours—that is true. One of the reasons we delayed the introduction of this container was we wanted to be sure that we had a resin that was 100 percent compatible with the PET recycling infrastructure. Tropicana business is just far too big for it to introduce a material that would interfere in any way with the PET recycling infrastructure. So we waited until a material was developed and we worked closely in this case with a resin supplier, Indorama, on their PolyClear EBM PET.

"The nice thing about this resin is it is fully compatible with PET recycling, and I can talk a little bit about how I can make that claim.

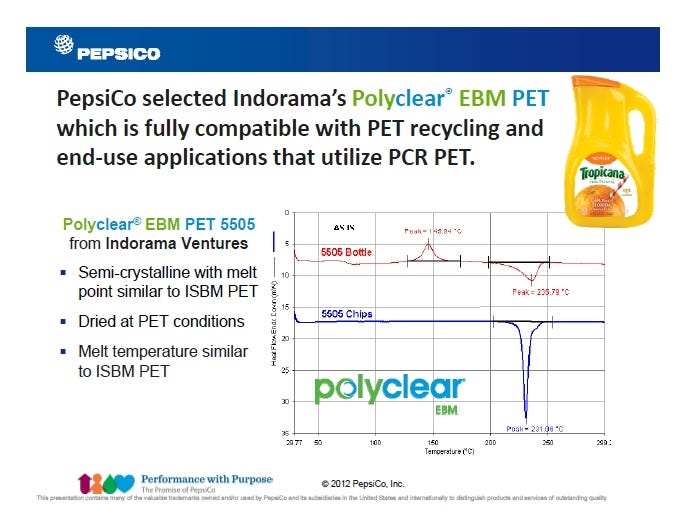

"As you can see from this diagram...

Tropicana Indorama chart

"The red curve represents bottle flake as it's heated. It crystallizes at about 146-deg C. So the material is crystallizable. That's important because, when you want to dry PET, you have to dry it at very high temperatures. And it's critical that you have a crystalline skin on the outside of the flake or on the pellet you're trying to dry to prevent sticking or agglomeration of the flakes or pellets.

"This material will crystallize, so when we process regrind in our plants, we're able to crystallize that regrind prior to introducing it into our drying systems.

"You can see the melting temperature of about 236-deg C. It's quite similar to that of standard bottle-grade PET. So this material, again, will not suffer any sticking or agglomeration issues when you try to dry it.

"When a recycler, for example, takes a bale and it's got up to 50 percent of these bottles inside that bale, he can confidently grind that up and dry it with his other ISBM [injection stretch blow molded] resin and not be concerned about any sticking issues.

"The bottom blue curve represents the in-bound or incoming resin. It's a solid-stated resin so the material is already fully crystallized when we receive it so you don't see any peak associated with crystallization as you heat the in-bound chips. They are already fully crystallized.

"This is the reason I can say this material is fully compatible with PET recycling: Indorama worked closely with the Assn. of Post-Consumer Plastics Recyclers—an organization that PepsiCo is an affiliate member of and many of the resin suppliers, converters and brand owners are members of—which supports PET recycling.

"APR recognized Indorama, that their resin fully meets both APR guidances.

"1. The so-called Critical Guidance protocol, which determines if a material is compatible with PET recycling. Can a recycler make a pellet that will meet a brand owner's requirements, for example?

"2. And it meets the Applications Guidance, which is, materials derived from these bottles were then tested in new 2-L PET bottles, as well as in sheet and fiber strapping applications, and they were deemed not to interfere or not have any negative impact on any of those end-use applications.

"The APR has a pretty rigid and aggressive protocol around the recyclability. And this particular resin met those requirements."

.

About the Author(s)

You May Also Like