Winpak REVOH tray

Food manufacturers seeking high-barrier packaging materials at a lower cost without performance trade-offs now have another cost-effective option to consider.

New REVOH technology from Winpak Portion Packaging Inc. is engineered to enhance the post-retort oxygen barrier of thermoformed containers by reducing oxygen ingress 30 to 35 percent during the critical time when the packaging's EVOH oxygen barrier layer is most vulnerable to penetration—immediately after retort.

The key to protecting this EVOH oxygen barrier—thus improving overall shelf life—lies with an improved moisture barrier elsewhere in the container's structure.

Softening the shock

Many existing retort food packages are multi-layer structures, with an EVOH oxygen barrier layer sandwiched between polypropylene layers. Alam Shah, Winpak's manager of technology, explains: "The basic functions of polypropylene layers are to protect EVOH from moisture and to maintain the structural integrity of the container when it is exposed to steam and elevated temperatures during the retort process. Polypropylene works well as a moisture barrier at ambient conditions, but it does allow excessive amount of moisture to pass through during the retort process, which renders EVOH temporarily ineffective."

Water molecules (steam) from the retort process permeate the outer PP layer and temporarily neutralize the barrier properties of EVOH, enabling more oxygen to enter the package right after retort, which negatively impacts shelf life. It takes about 10 to 14 days for (almost) full recovery of the oxygen barrier properties of the EVOH layer as the material reaches equilibrium. But Shah explains, "Most of the oxygen that enters the package is in the first few days after retort. The most significant impact of retort is in the first 100 to 200 hours."

The REVOH technology protects the EVOH barrier layer from this "retort shock" by adding micron-sized minerals to the outer PP layers comprising of a specifically formulated blend of resins and additives to boost their moisture barrier.

Shah says, "Containers made with REVOH technology show one third weight gain due to moisture absorption during retort compared to containers of the same size and EVOH content produced with the current commercial technology."

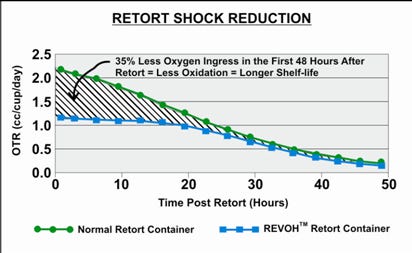

The chart, based on independent testing commissioned by Winpak, shows how REVOH reduces the impact of retort shock in food packages compared to the typical PP barrier structure. Reduced moisture ingress during the retort process results in about 30 to 35 percent lower post-retort oxygen transmission.

Winpack REVOH chart

More and less

The benefits of this patent-pending technology are multifold.

• Longer shelf life: The exact amount of additional shelf life will depend on a variety of things (such as the grade and amount of EVOH used), but Shah says if oxygen is the primary culprit for the reduction in shelf life, then a REVOH container with the same EVOH concentrations as an existing PP/EVOH/PP retort package will deliver "significantly" more shelf life.

• Performance enhancements: Shah recites a litany of features that the REVOH technology offers—improved moisture barrier compared to standard PP containers; improved rigidity, especially at elevated temperatures; about 18 to 27 deg F higher heat-deflection temperature for better microwave performance; good impact resistance at low temperatures; and about twice the thermal conductivity of similar containers made with non-REVOH technology for efficient and uniform heating of the contents.

• Environmental impact: Compared to traditional PP retort food containers, REVOH containers use 20 to 40 percent less petroleum-derived polymeric materials by adding minerals in their place.

• Cost/materials savings: According to Matt Ryan, product development manager, a REVOH container with 30 percent less EVOH will have the same oxygen transmission rate (OTR) as a comparative non-REVOH container, which can result in cost and material savings for customers.

Customer trials are currently taking place and Winpak, Ryan emphasizes, is committed to providing a cost-effective solution to the marketplace.

Winpak Portion Packaging Inc., 267-685-8251.

www.winpak.com

.

About the Author(s)

You May Also Like