January 30, 2014

New HP printer cartridge packaging benefits retailers, consumers and the environment.

Long after the paper bag became the standard package in which consumers could carry home everything from groceries to clothing to hardware products, the use of the material as a packaging medium has continued to evolve. Paperboard cartons, offering highly visible "billboards" for creating shelf presence, and corrugated shippers to protect and promote products on their way to market, have become increasingly popular.

The introduction of waterproof plastics led to the development of coated paperboard shippers to defend against the intrusion of moisture. Similarly coated, protective packaging proved its ability to maintain its shape and resist bumps and scrapes during shipping, even in high-moisture environments.

Today, as the need to be more environmentally responsible assumes a higher priority and plastics are being developed that are recyclable and/or compostable, many coated paperboard products are undergoing their own evolution toward greater sustainability by becoming more recyclable without sacrificing any of their strengths as protective packaging. In addition, users of paper and paperboard packaging have found a variety of new ways to use and reuse this "natural," recyclable material.

RecyclaCorr(TM) is a recyclable version of waxed corrugated.

Many of these new paper-based products—and other developments in paper packaging that support sustainability—will be on display at PACK EXPO Las Vegas 2007 (www.packexpo.com), Oct. 15 to 17 at the Las Vegas Convention Center. Following are just a few examples of the products that will be featured.

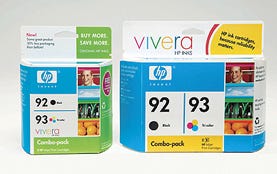

With its major effort to decrease the volume of paperboard used to package printer ink cartridges sold in North America, Hewlett-Packard (Booth S-5060) will reduce the greenhouse gas emissions produced in making and shipping display packages for the cartridges by an estimated 37 million lb in 2007—equal to taking 3,600 cars off the road for one year.

How is this possible? As a direct consequence of cutting the volume of packaging material, the company reduces both the amount of processing needed to make the packaging and the fuel needed to transport the lighter-weight cartridges to market.

For HP's Laser Jet cartridges, for instance, the new packaging will use approximately 45-percent less packaging material. Each pallet will hold 30-percent more cartridges, while each shipping container will carry about 1,500 more cartridges. Redesigned ink-jet multipacks use 85-percent less material (by weight), and twice as many of the new packages will fit on a pallet. The smaller packaging also lets retailers display more packages per shelf.

Another change, according to HP's manager of environmental policy and strategy, Scott Canonico, and packaging engineer and new product planner for LaserJet, Jill Wollam, is that pallet loads shipped from manufacturing sites to distribution sites employ corrugated slipsheets in lieu of wooden pallets. This enables HP to make loads higher and ship a higher volume of product per truck or container.

The attention being given to sustainability has led to the development of new environmentally acceptable packaging materials and practices.

HP's ink-jet business implemented changes to packaging for some of HP's small-format cartridges. Large-format cartridges, such as those used in packaging operations, have utilized up to 80-percent-recycled-content paperboard packaging for several years.

"This change began when we considered ways to improve the customer experience by redesigning the interior bags used to seal LaserJet cartridges and making the packaging easier to open," Wollam points out.

The result is a solution in which everyone wins: HP, retailers, consumers and the environment.

Smurfit-Stone Container Corp. (Booth C-2423) created RecyclaCorr(TM) as an alternative to the wax-impregnated boxes traditionally used to ship fruits and perishables. These wax-protected corrugated boxes were originally designed to resist the water or high humidity associated with fresh produce. The wax protected the board from water damage that could weaken the strength or integrity of the container and prevent failure during storage and shipping.

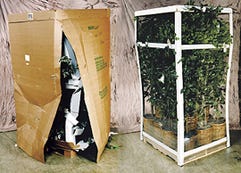

VBoard protects trees'both silk and real.

But waxed boxes cannot be easily recycled, if at all. As a result, disposal and labor costs for the retailer can increase. RecyclaCorr trays and boxes are not only constructed from a medium that is totally recyclable, but are—because of their moisture-resistance—reusable, converting what was often a disposal cost into an asset. RecyclaCorr is also safe for indirect and direct contact with food.

Laminations(R) (Booth S-5126), which is part of Great Northern Corp.'s Specialty Group, aims to protect the environment in two ways. First, it produces effective and recyclable edge-protection paper products from 80-percent post-consumer and 20-percent pre-consumer waste. Second, it protects products during shipment with the minimum amount of material, as demanded by an increasing number of retailers, substantially reducing the amount of material to be disposed of after the fact.

Laminations' newest edge protectors are laminated paperboard that is coated to provide extra product protection by resisting absorption of various forms of moisture that the company says might reduce their effectiveness and by decreasing the chances of scuffing or abrasions on fine finishes.

Options include HydroShield(TM), which features a moisture-resistant coating and is especially effective in the protection of produce and perishable foods. The company's PetroShield(TM) product resists oil and grease, meaning it does not absorb lubricants that could remain on the products they are protecting, such as metal machine parts. Finally, ScuffShield(TM) features a coating that protects products with delicate surfaces—fine furniture and appliances, for instance—from scuffing during shipment.

What these products do not resist is recycling. All the coatings are as pulpable as the paper materials they protect.

As for reducing material use, the protective shipping "cage" for a silk tree, for instance, is created by combining a Laminations PF Pallet Top(R) with a frame of VBoard(R) edge pieces that rise from a wooden pallet. The resulting stable structure is then wrapped in plastic film to create a secure shroud for the plant while eliminating the large corrugated box previously used.

Custom Paper Tubes (Booth S-6001), as its name suggests, produces custom-designed paper tubes for a wide variety of companies in many industries. Its paper tubes are recyclable, and many of them use recycled post-consumer waste as a percentage of their content.

"That isn't always possible," points out Custom Paper Tubes' director of marketing, Phil Van Duyn. "Food products require clean, food-grade paper tubes. Not all post-consumer waste meets that standard," he says.

Reveal® see-through tubes are eye-catching and recyclable.

One of the company's most recent introductions is its Brite White(TM) disposable medical mouthpiece, a U.S. Food and Drug Administration-approved device made of 100-percent food-grade material, including no recycled waste. The tube is coated with a proprietary food-grade paper wrap to prevent it from wicking moisture as it is being used, which can cause patients dry mouth discomfort. Tubes are available in various sizes to fit all inhalation equipment and are completely recyclable.

Custom Paper Tubes is an FDA-registered medical device manufacturer, which ensures that it is compliant with FDA Manufacturing Procedures.

"That is necessary to be able to produce the Brite White mouthpiece," says Van Duyn, "but it also helps project to our other customers the high level of quality manufacturing we produce."

Another of the company's newer introductions is its Reveal(R) line of see-through canisters, which combine the visibility of transparent, food-grade recyclable plastic (polyethylene terephthalate glycol) extruded tubes from a manufacturing partner with the color choices and printability of paper tubes and lids. These attractive canisters are available with inside diameters up to 5 in., in 1-in. increments.

As concern for the environment rises among both shippers and consumers, Pacific Pulp Molding (Booth S-5062) has seen inquiries about its molded-pulp protective packaging rise more than 60 percent. Shippers are exploring this alternative to expanded polystyrene (EPS) protective packaging. Several of those inquiries have converted to sales, and the company is currently in the process of expanding its production facility to meet growing demand.

Recyclable molded pulp protects delicate products and dampens vibration.

"Molded paper pulp has been available for years," points out the company's owner and founder, John McNeil, "but sustainability issues have now shone the spotlight on us. Rising costs for EPS, which is petroleum-based, coupled with the recyclability of molded pulp, make us the environmentally sound choice. The new attention has led companies to learn about the superior cushioning protection offered by pulp against both G forces and vibration."

Tests conducted by independent university researchers have shown that molded pulp reduces G forces significantly more effectively than EPS and dampens vibration three times more effectively.

Pacific Pulp customers, including Bose(R) Corp., have converted from EPS to molded pulp to cushion sensitive electronic products during shipping and use it for the inside of primary packaging. Increasingly, retailers including Wal-Mart, have attended International Molded Pulp Environmental Packaging Assn. (IMPEPA [www.impepa.org-]) seminars, in which Pacific Pulp was a participant, to learn more about pulp's advantages: better cushioning; lower cost; and environmental friendliness.

Other advantages include freedom from static electricity and the influence of temperature, and the capability to nest, saving both storage space and packaging assembly time.

While being recyclable itself, pulp is produced from 100-percent post-consumer-recycled paper materials, adding to its environmental benefits. It meets both ISO 14000 and European Green Dot standards, whereas EPS is banned from most European countries.

Pacific Pulp produces both stock forms (candle protectors, edge protectors, etc.) and custom forms designed to meet specific customer needs (for modems, setup boxes, etc.). Custom forms are designed using Solid Works design software that produces three-dimensional drawings. Customers provide the company's engineers with either their product or accurate engineering drawings from which to work.

The attention being given to sustainability has led to the development of new, environmentally acceptable packaging materials and practices in every area of packaging. Many of those will be on display at PACK EXPO Las Vegas in October in the Containers & Materials Pavilion.

To register for PACK EXPO Las Vegas 2007 or to obtain more information, visit www.packexpo.com or contact PMMI's Show Department at 703/243-8555; fax: 703/243-8556; or e-mail [email protected].

More information is available:

Custom Paper Tubes, 800/766-2527. www.custompapertubes.com.

HP Specialty Printing Systems, 858/655-3879. www.hp.com.

International Molded Pulp Environmental Packaging Assn. (IMPEPA), 262/241-0522. www.impepa.org.

Laminations, 800/925-2626. www.laminationsonline.com.

Pacific Pulp Molding, 619/977-5617. www.pacificpulp.com.

PACK EXPO Las Vegas, 703/243-8555. www.packexpo.com.

Smurfit-Stone Container Corp., 877/772-2932. www.smurfit.com.

You May Also Like