Sealed Air’s prismiq suite of digital technologies for printing, smart packaging, and design takes flexible packaging in a more connected direction.

Sealed Air, which has rebranded as SEE, is integrating digital technologies with physical packaging — including flexible packaging used for food — through its new prismiq digital packaging brand. The prismiq portfolio combines the best of digital printing, smart packaging, and package design services that support those technologies.

SEE’s digital transformation represents a roughly $100 million investment. Through prismiq, brand owners can access:

Customized digital printing solutions, including on-demand digital printers for packagers’ own facilities and large-format digital printing executed by SEE;

Smart packaging solutions that use a cloud-based platform to generate package-specific digital identifiers;

A suite of design services geared to digital connectivity.

The digital printing portion of the prismiq portfolio offers brand owners greater print flexibility and more personalization options. The smart packaging portion provides a path to deeper relationships with consumers, based on engaging digital experiences, as well as improved supply chain transparency.

“This portfolio of services, technology, and equipment can bring growth across the value chain,” said Carrie Giaimo, SEE’s executive director of global smart packaging and design, at prismiq’s spring 2022 launch event.

Potential operational benefits for packagers include improved quality assurance, inventory visibility, rework reduction, and enhanced automation.

“We are also ready to unlock the possibilities of consumer experience with every package, including brand enhancement, package engagement, loyalty programs and campaigns, [and] product transparency,” Giaimo added. “Some examples of how to use this digital ability are: sustainability, track and traceability, speed to market, behavior and trend data.”

A digital printing revolution in speed-to-market.

SEE’s digital printing technologies offer easy updates to package designs, multiple designs in one run, and package-specific serialized/digitized codes and images. The technology also can accommodate more variability in order quantities and provide faster turnaround times than conventional print technologies.

The prismiq portfolio includes digital printers for all print-format sizes. Years in development, the large-format prismiq 5540 digital printer is a highlight of SEE’s new digital platform.

At the prismiq launch event, Emile Chammas, SVP and chief operating officer of Sealed Air, described the 5540 printer as revolutionary.

“Having this new level of capability with digital printing technology brings us to a class of our own,” Chammas said. “This technology today does not exist for the types of materials and the types of customers that we serve. [It] will completely revolutionize how we print on our materials for our customers.”

Installed in a North American SEE facility, the prismiq 5540 can print a range of substrates, including rollstock films, shrink bags, mailers, and fiber-based packaging. The printer uses camera feedback to make changes and adjust constantly, delivering photographic-quality printing.

“The prismiq 5540 is the world’s largest, fastest printer specifically for flexible packaging, Joe Lambert, VP of global digital packaging solutions at Sealed Air, informs us.

Shown below, the 5540 features include full-color, wide-format (54-inch) printing at high speeds; the printer is also compatible with metallic and invisible inks.

In addition, the prismiq 5540 can “print on both sides of flexible and shrinkable materials, including fiber and plastic substrates,” Lambert explains. “This printer is designed to support demanding packaging applications that need to stand up to the rigors of shipping and temperatures, while maintaining a quality printed image.”

The printer is a time saver as well, enabling packaging to go from design to imprints in days vs. the weeks it would take with conventional equipment.

Each package can be tagged with a code — a quick response (QR) code or radio frequency identification (RFID) tag, for example — providing it with a unique identity and enabling tracking and tracing throughout the supply chain.

Pesonalization via on-site, small-format printers.

For customers that prefer to do their own digital printing, SEE offers small-format printers that integrate easily into brand owners’ packaging lines and can create retail-ready packs. Some of the company’s small-format digital printers are a mere one-tenth the size of a traditional, analog system.

“Our small-format digital printers are focused on adding personalization at the point of packaging for our customers,” Lambert explains. “This means units will be installed at customer locations either as an upgrade to our existing packaging equipment or a standalone unit for printing.” Personalization, added on demand, may come in the form of images, messages, or codes.

Customized systems are currently in trial across some core SEE applications, including right-sized boxing, Autobag brand automated systems, and shrink-bag loading.

“We hope to commercialize some of the systems in early 2023,” Lambert says, adding that SEE is currently in field trials with select ecommerce and food-proteins companies.

These projects include the installation of a modular printing system that enables branding and personalization of boxes at the point of packaging. The company is also developing systems that can add simple print on plastic substrates.

SEE’s recent acquisition of Foxpak, an Ireland-based digital packaging company that pioneered digital printing on flexible packaging, will aid the global expansion of SEE’s digital print operations.

Consumer-engaging smart packaging.

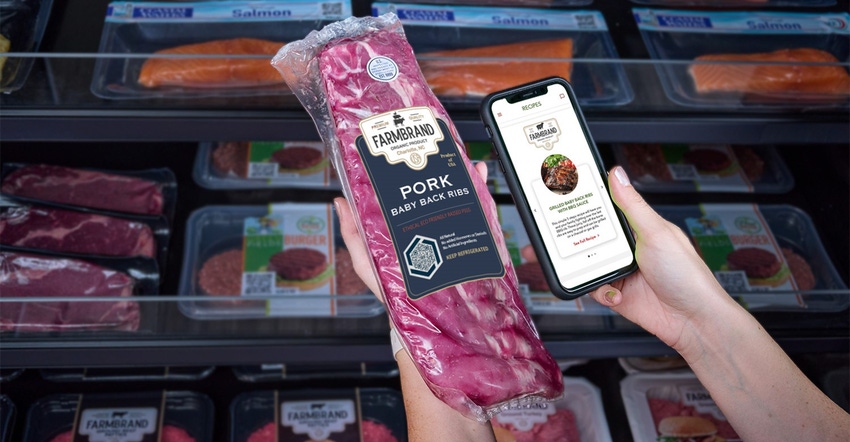

Complementing these digital printing innovations, prismiq’s smart packaging solutions enable brand owners to engage consumers with digital experiences. Using a smartphone, the consumer simply scans an on-pack code or SEE’s new active badge.

The company informs us that the SEE active badge represents a physical product having a digital twin in the product cloud. The digital twin contains product information that customers want to link to their package. The SEE active badge technology can work with any type of printed code or RFID technology to link the physical product with its digital twin.

Scanning offers consumers access to curated experiences and content. Examples include brand- and product-related content such as nutrition and allergen facts, package recycling information, recipes, coupons, loyalty programs, and contests.

“Prismiq is about more than printing and design; it’s also focused on connection. We have connected packaging services that complement our digital printing solutions,” Lambert explains.

“These services allow our customers to link product data to each package within our cloud and then convey that information to consumers through custom-designed user experiences,” he adds. “By providing this end-to-end solution, we intend to make smart packaging easy for our customers.”

In partnership with Digimarc, a leader in product digitization, SEE is focusing on at-scale smart packaging for categories such as food proteins, ecommerce fulfillment, industrial products, and consumer goods.

Product digitization refers to giving each product a unique digital identity in Digimarc’s Evrythng Product Cloud. Digimarc provides the product identification using its unique digital watermarking technology. Thus physical packages can connect with the internet.

For manufacturers and brand owners, the three key benefits of digitizing products are consumer engagement, brand protection, and supply chain traceability. Product digitization also creates a channel for engaging consumers directly.

“By allowing consumers to scan product packaging with their smartphones, we can provide valuable information about those products. We can tell them about their ingredients, where the products were made, how they were made, who made them,” said Curt Schacker, global head of print and packaging at Evrythng, a Digimarc company, at prismiq’s launch event.

“All of that information comes to light through the combination of a digital identity, a QR code, a digital watermark on the packaging in combination with the consumer’s smartphone,” he added.

In an April 2022 survey of 4,064 consumers in the United States and United Kingdom, 73% of participants said being able to verify that a product is authentic is important. Fully 56% said transparency into how and where a product is made (ethical production) influences purchasing decisions, and 60% indicated that being able to recycle packaging is important. Censuswide conducted the Digimarc-sponsored survey.

Prior to SEE and prismiq, no company had “come forward with the ability to print serialized, variable images onto flexible packaging. Through serialization, we can enable brands to unlock the full potential of product digitization, and it’s really exciting to see Sealed Air enabling that for the flexible packaging space,” Schacker said.

Nearly 200 design service specialists.

Prismiq design services include structural and graphic packaging design, prototyping, engineering, technical trials, and print system design and implementation. Nearly 200 design specialists at SEE work with packagers to create custom graphics, develop new pack concepts, and conduct performance testing.

SEE is also partnering with the Savannah College of Art and Design (SCAD) in the provision of prismiq design services. In an initial project, SCAD students have been designing an online design portal for SEE that will enable brand owners to customize their packaging.

“SCAD helps us with conceptual designs of our digital solutions that are intuitive and easy to use, like our online Design Studio,” Lambert says. “These solutions will impact all of our customers as they connect with Sealed Air using our online Design Studio, launching later in 2022.”

Lambert adds that there will be opportunities, going forward, to bring SCAD into customer projects for conceptual design or new product launches. The idea is “to help expand our collective creative thinking.”

About the Author(s)

You May Also Like