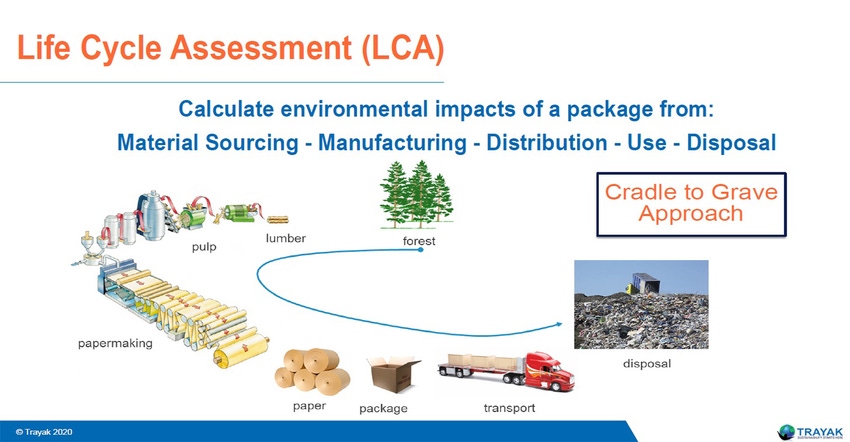

An expert reveals six takeaways that will help ensure success when conducting a Life Cycle Assessment for packaging.

February 8, 2021

Sustainable packaging decisions establish a firm, better-to-justify-and-defend position when founded on science, facts, and data. One of the tools that helps clarify decision-making and allows metrics-based benchmarks and comparisons for sustainable packaging is a Life-Cycle Assessment.

As President of Trayak, Prashant Jagtap is immersed in LCAs for packaging. He responded to our questions summarized as six takeaways.

1. Reducing packaging materials remains the lowest-hanging fruit with the fastest ROI.

Designing minimal packaging that still protects the products while communicating the brand message should be the goal of every packaging engineer. This reduction can be achieved by eliminating some packaging components altogether. Some examples of what can be eliminated are polybags, instruction booklets, some printed labels, etc.

In other cases, light weighting components has worked by down gauging films and papers, for example.

Shrinking package size can also provide many benefits beyond just saving material cost. Saving money on shipping and right-sizing shelf space can add to the benefits.

Companies were quick to adopt this because it also reduces cost and usually provides the highest return-on-investment. Overall, many companies manage to reduce material use between 20-50%, which is a substantial for high-volume materials. It might easily justify changes in tooling, molds, or filling processes.

The key is to make sure the damage rate of the product doesn’t go up.

2. Avoid the preconceived idea that some materials such as certain plastics are bad.

When clients perform an LCA and compare that to other more sustainable materials, they can be sometimes surprised with the results. For a given function, packaging components made from different materials will have different weights.

Sometimes a “bad” material might still be the sustainable choice because it reduces overall material use, provides superior protection, and could also help with stacking more product on a pallet. A systems approach of looking at a pallet load can provide results that are not obvious or expected.

Another thing to remember is to use plastics in a way that retains the recyclability — avoid using dyes, colorants, additives that may make it difficult to recycle. Also make sure consumers are easily able to separate the components for recycling.

3. Don't be mislead by a narrow goal when conducting an LCA.

Focusing on one package component instead of looking at the entire system of primary, secondary, and tertiary packaging can be misleading.

Also, focusing on just one LCA indicator like greenhouse gas (GHG) measurements can also be misleading.

Burden shifting is a common issue. Typically, at a large organization, the packaging engineer will not be responsible for all the packaging to ship a product. It becomes easy to just optimize the package you are responsible for without understanding implications on the other packaging required to safely ship the product.

From an LCA perspective, different indicators might sometimes exhibit opposite behaviors. A classic example are bioplastics. Usually GHG reductions will be achieved, but water consumption and Aquatic toxicity or Eutrophication might go up. Clearly to grow crops like corn and sugarcane there is need for water, fertilizers, and pesticides. These inputs will negatively increase the three indicators mentioned above.

4. Shifting from rigid to flexible packaging structures usually shows dramatic reductions in LCA impacts.

The reductions in environmental impacts of the primary packages are usually supplemented with additional savings in secondary packaging and efficiencies in palletizations.

I've always been amazed with how dramatic these reductions can be, though flexible packaging is typically unrecyclable in a typical municipal infrastructure.

5. Understand the tradeoffs.

Decisions about reducing environmental impact cannot be made while ignoring or not fully understanding the impact on the functional and cost requirements on the package. It is important to be able to understand the tradeoffs. All engineering designs for packaging or products are essentially tradeoffs. Any LCA tool you use should allow you to understand and make those tradeoffs easily. It is therefore important to understand how implementing a sustainable package design impact your cost, or damage rate, or shelf life, or palletization. EcoImpact – COMPASS and SCORE allows you to tradeoff between your LCA indicators and about 20 different package performance attributes.

6. It’s a myth that LCAs are expensive and time consuming.

Historically and for the 40+ years LCA methodology has been used, this has been true, so the myth is not entirely unfounded. If a generic and flexible LCA tool is used, it does require deep knowledge for someone to set up a model to analyze and then to interpret the results.

However, for the last 10+ years LCA tools like EcoImpact-COMPASS have been created for specific domains like packaging. This tool can be used by any packaging engineer with 45 minutes of training. Within 20 minutes they can start analyzing their packaging and make decisions, thus it is a misconception that LCA is very expensive and time consuming. In fact, it can be affordable, accessible, and easy to use.

Without such software, mainstreaming sustainability using a science-based platform would be impossible.

Do you have any LCA questions for Jagtap? Ask it in the comments below or send an email to [email protected] and we’ll forward it to him.

See also our previous interview with Jagtap, An Introduction to Life-Cycle Assessment for Packaging, published December 2020.

You May Also Like