Advanced algorithms determine which items to take out of the box and put into envelope mailers, significantly reducing the etailer’s carbon footprint.

December 7, 2020

Amazon reports that, since 2015, it has reduced the weight of its outbound packages by one-third by eliminating 915,000 tons of packaging material worldwide or the equivalent of more than 1.6 billion shipping boxes. Less volume in shipments equate to reduced transportation impact and ultimately to reduced environmental impact — fewer trucks on the road deriving more products with reduced carbon footprint.

Leading brands have partnered with the Amazon Web Services (AWS) customer packaging experience team to use data analytics in making packaging improvements. For instance, statistical models help optimize packages for reduced damage and lower costs, and the use of the AWS machine learning (ML) tools and services give data scientists the tools to build, train, and deploy advanced models at scale.

How machine learning affects ecommerce packaging.

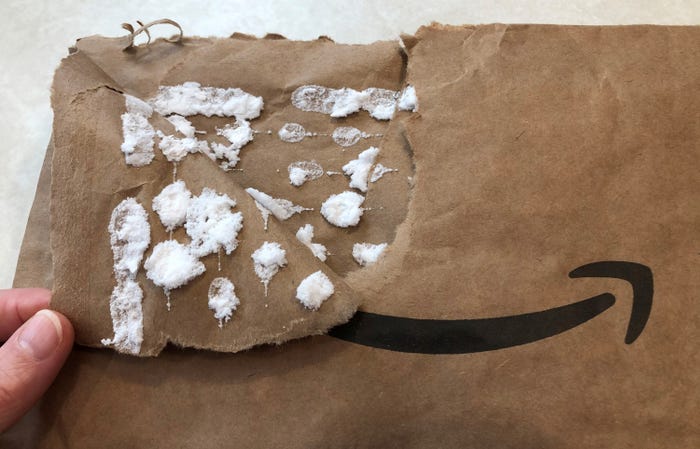

ML is a method of analyzing large and growing datasets to reveal patterns and make automatic improvements to optimize systems. Amazon has used ML “to discover a number of ways to eliminate waste,” says Kim Houchens, Amazon’s director of customer packaging experience. In her keynote November 9 during the virtual Pack Expo Connects event (you must register to view the free presentation). She cited a massive reduction of waste by shifting many items from boxes to padded envelope mailers.

Just weeks earlier, the company reported that as of 2020, ML tools have reduced the use of boxes from 69% to 42% in favor of padded mailers. Mailers (padded paper envelopes) are 75% lighter than a box and occupy 40% less shipping space. This followed Amazon’s package development partnership with Henkel and the 2019 launch of a fully recyclable padded mailer (see below) that protects and minimizes transit space requirements. When heated, the adhesive holding the two layers of paper together expands to provide cushioning, without negatively affecting the mailer’s recyclability.

ML-enhanced analytics helped the company decide which products could be migrated from boxes to mailers without adverse results, such as damage to the product. Before the analytics project, Amazon relied on general rules, such as packing all vinyl toys under $25 in a flexible mailer.

“However, it turns out that there are a lot of exceptions to those rules,” according to Matthew Bales, research science manager. And ML was uniquely suited to “dig into” all of them to find, for instance, that collectible action figures require the extra protection of a box. There was no other way to efficiently and effectively make such determinations using lesser software routines, much less humans poring over data relating to “hundreds of millions of products, billions of customer shipments, and multiple channels of customer feedback.”

Forcing change for good.

Amazon’s grand vision is spelled-out in the Climate Pledge initiative it co-founded in 2019, and whose signatories now include hundreds of private- and public-sector brands and others pledging to achieve net-zero carbon emissions across their businesses by 2040, a decade ahead of the Paris Accord’s 2050 target.

“It’s going to be challenging, but we know we can do it and we know we have do it,” Amazon CEO Jeff Bezos said in co-founding the initiative.

Amazon is in a prime position to move the market beyond its ecosystem due to the presence of its online marketplace and AWS’ market share. With a one-third share of the cloud services market, it far outstrips runners-up Microsoft Azure and Google Cloud.

About the Author(s)

You May Also Like