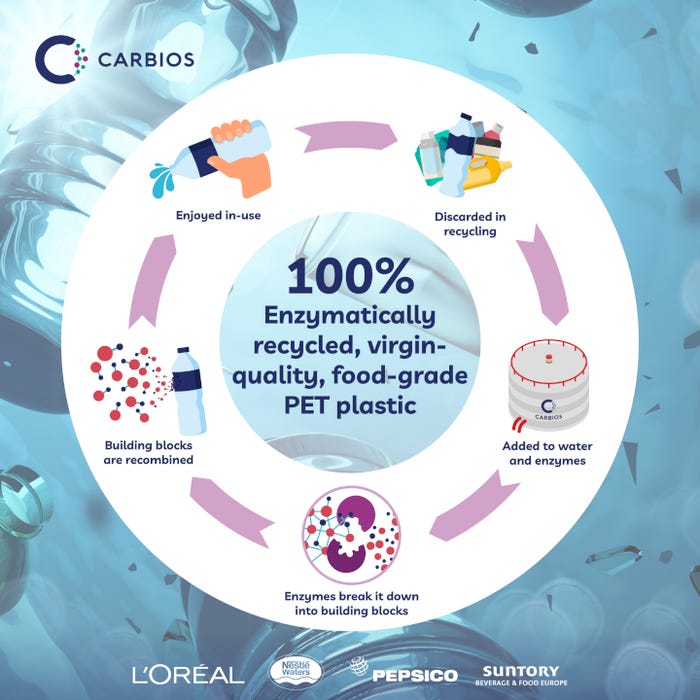

The Carbios PET recycling technology uses enzymes to transform post-consumer PET to food grade, virgin quality recycled material, and gains support from four major brand owners.

Together, in what they’re calling a “world’s first,” L’Oréal, Nestlé Waters, PepsiCo, Suntory Beverage & Food Europe, and Carbios have proved the feasibility of making food-grade polyethylene terephthalate (PET) bottles from 100% post-consumer waste that was biologically recycled.

Each consumer packaged goods (CPG) company has been successful in making prototype bottles from material produced using the patented Carbios enzymatic recycling process for their select brands (see photo above):

L’Oréal’s Biotherm

Perrier from Nestlé Waters

PepsiCo’s Pepsi Max

Orangina from Suntory Beverage & Food Europe

In support of this development, Roberto Vanin, chief R&D officer for Suntory Beverage & Food Europe, says, “The global issue of plastic waste requires transformational thinking, creative partnerships, and innovative brands coming together to seek out new solutions. Continued investment in new ways of tackling waste and creating true circularity such as this ground-breaking technology from Carbios will be key to Suntory Beverage & Food Europe achieving its 100% sustainable plastic ambition.”

Touted as a breakthrough in biological recycling, the Carbios technology uses enzymes naturally found in decomposing compost heaps to break down 97% of PET in 16 hours. The enzymes are first “supercharged” by Carbios, then tasked to do their thing. Carbios says its process is 10 thousand times more efficient than other existing trials of biological plastic recycling.

The Carbios-optimized enzymes are able to break down any kind of PET into its monomer building blocks — terephthalic acid and ethylene glycol — regardless of the PET’s color or complexity, according to the June 24, 2021, press release announcing this development. The recycled material can then be used to make clear “like-new, virgin-quality plastic,” according to the press release — what Jacques Playe, L’Oréal’s global head of packaging and product development, calls “the packaging of the future.”

Multiple benefits aid brands’ sustainability efforts.

How is the Carbios enzymatic recycling process different from other recycling technologies?

• Broad use: This alternative to mechanical recycling can process any type of post-consumer PET plastic, including colored material or PET plastics that would otherwise go to a landfill or be incinerated. Jean-Francois Briois, head of packaging material science and environmental sustainability for Nestlé Waters global R&D, says, “It is very exciting to see that the quality of the prototype bottles made from colored recycled PET materials is virtually identical to clear virgin PET. When we reach industrial scale, this enzymatic recycling technology will enable us to produce high-quality rPET bottles and help Nestlé Waters in our journey to boost the circular economy and reduce the use of virgin plastics.”

• Lower carbon footprint: While optimized to scale up to commercial volumes, the Carbios enzymatic process works under “mild conditions.” The treatment reduces CO2 emissions by 30% compared to conventional incineration or landfill. The process is also less taxing than virgin PET production, according to a preliminary results of a 2021 life-cycle assessment (LCA) of the Carbios process.

• Closed-loop system: Ron Khan, global VP of packaging for PepsiCo Beverages, says, “We are dedicated to reducing the virgin plastic we use. With the breakthrough Carbios enzymatic recycling technology, we can help keep valuable material in the circular economy, reduce waste, and take another step toward a truly closed loop system.”

The four participating brands will continue to collaborate to scale up the process for future use. Production will be in two stages: Carbios plans to start building a pilot plant in September 2021, then intends to open an industrial facility by 2025 with the capacity to produce 40,000 tons of biologically recycled PET annually.

To speed up global adoption of enzymatic recycling for PET packaging, Carbios will also license its technology to PET manufacturers worldwide.

About the Author(s)

You May Also Like