November 27, 2019

Nestlé USA packaging specialist details the highly engineered bottle and innovative sleeve label that enabled the development of 100% recyclable sleeve-labeled bottles.

Time can deliver a whole new perspective on things.

In July, Nestlé and Starbucks announced the launch of Starbucks Creamers that enabled the Starbucks brand to break into the refrigerated creamer category. The product development combined Starbucks’s popular flavors with Nestlé expertise and leadership in the creamer category. The result? Consumers have a new way to enjoy Starbucks coffee at home.

That was all interesting, but it was essentially a branding breakthrough rather than a packaging innovation.

That changed when it was revealed this month that the Starbucks Creamers PET bottle and shrink-sleeve label are 100% recyclable. This is a first for the Nestlé USA’s packaging portfolio, which seeks to reach 100% recyclable or reusable packaging by 2025. Now that is noteworthy packaging news!

That prompted connecting with Nicole Camilleri, Nestlé’s technical packaging senior development specialist. Before jumping into the packaging details of the achievement, here are some key product highlights:

There are three flavors in the line, Caramel Macchiato, White Chocolate Mocha and Cinnamon Dolce;

The products arrived in refrigerated cases beginning this August;

The refrigerated products have a 180-day shelf life and should be used within 14 days after opening or before the use-by date, whichever comes first;

This launch is part of the global coffee alliance announced earlier this year when Nestlé introduced a range of 24 Starbucks products across various platforms.

How complex was the project?

Camilleri: The project was complex because of the rapid timeline and unique bottle design. We launched Starbucks Creamers in less than a year from inception to shelf, the fastest project with a custom bottle and closure Nestlé USA has implemented. We custom-designed the bottle to emulate carafes from Starbucks and the lid is a one-touch pour, created to truly be opened and closed easily with one hand.

Additionally, the closure, shrink sleeve, corrugate tray and palletization pattern were all custom designs. We did this while challenging ourselves to use new materials and incorporating recyclability into the design, utilizing new technology to incorporate a fully recyclable shrink sleeve.

What are the key materials and for what recycle stream(s)?

Camilleri: The shrink sleeve is made from a PET resin that is PET recycling stream compatible with washable inks. This combination of recyclable base material and washable inks are recognized by the Association of Plastics Recyclers (APR). This shrink-sleeve technology not only allows the consumer to recycle the bottle with the shrink sleeve still attached, but it allows the shrink sleeve material to be captured and recycled within the mechanical recycling process. Both the bottle and the closure are custom designed for Starbucks Creamer.

The entire bottle including the shrink sleeve can be disposed into single stream recycling and will get sorted into the #1 stream. This makes it easy for a consumer to recycle the bottle in their blue recycling bin without having to manipulate it in any way.

Which packaging component was the most challenging?

Camilleri: Each component had its own unique challenges to overcome for which we found solutions:

Aesthetically, the bottle is deliberately smooth walled and free of ribs; it was designed in a manner to flex to provide vacuum resistance without the bottle paneling or ovalizing.

The closure was a custom two-piece design where the main challenge was to balance the force required to keep it closed throughout the manufacturing process however open properly for consumer use.

Finally, the label was challenging because it was the first PET recyclable shrink sleeve that both the shrink-sleeve converter produced and Nestle utilized, so there were learnings both from a converter standpoint as well as running on the Starbucks creamer production line.

What partner/vendors were involved to make this happen?

Camilleri: Eastman Embrace Encore copolyester is used for this recyclable shrink sleeve material. According to Haley Werth, market development manager at Eastman, “We are thrilled to be a part of helping Nestle achieve their goal of 100% recyclable packaging with Eastman Embrace Encore copolyester, an APR Critical Guidance recognized product. We see this as an important milestone in the sustainable transformation of our shrink-film resin portfolio and a model for how Eastman can work with the industry to implement circular solutions that positively impact our world.”

The base film is Eastman Embrace Encore and the converter is American Fuji Seal Inc. with the product of RecShrink (base film + washable inks).

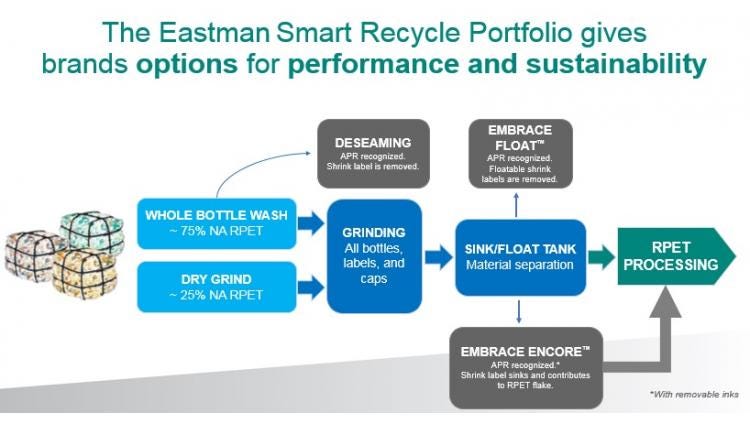

Graphic: Eastman

According to American Fuji Seal, “American Fuji Seal is pleased to have commercialized our new film development, RecShrink, with Nestlé to further enhance our sustainability platform. RecShrink is a crystallizable shrink sleeve material, decorated with American Fuji Seal’s washable solvent ink, which allows for film material to be recycled along with PET bottle materials. Historically, shrink-sleeve labels have been deemed a bit of a black eye within the recycling community because of the contamination and their physical properties related to it being a ‘low melt’. Because of the lower melting point, contamination and degradation of the recycled materials can occur. RecShrink is designed with a higher melting point so clumping will not occur in the drying systems, which would diminish rPET quality.”

Are any of these vendors new to the company?

Camilleri: For this design we worked with existing vendors.

What potential does Nestle see in this and other recycling technologies?

Camilleri: Nestlé has committed to 100% recyclable or reusable packaging by 2025 and we are making progress toward that goal. Nestlé is developing and implementing many different technologies to address packaging sustainability. We have a large global R&D community including the Nestlé Institute of Packaging Sciences who are developing new solutions to apply across our portfolio. As with any sustainability innovation that we implement, we are always evaluating how we can reapply technology to other products in our portfolio.

Is this the same sleeve technology used by Nestlé Waters North America for the 100% recyclable bottle/sleeves/caps for the new DC superheroes line?

Camilleri: Nestlé Waters North America is using a different shrink sleeve technology for its new Nestlé Pure Life DC Collection of superhero-themed bottles. Nestlé is actively implementing many different technologies to improve sustainability across our vast packaging portfolio.

In terms of form and function, what were the design goals for the packaging?

Camilleri: Our custom Starbucks Creamer bottle design was rooted in our consumer obsession. The design was inspired by Starbucks brand attributes and the Starbucks café experience, informed by targeted consumer insights and incorporated category norms and functionality. We designed the bottle to include flowing, soft curves and a simple, balanced shape. The closure was designed to mimic carafes found in Starbucks cafés, and to create an easy and mess-free pouring experience. We also designed for the ideal flow from of creamer from the spout and a “click” sound to cue that the lid is closed.

Can you comment on the products’ reception?

Camilleri: While we cannot share specific sales information, we have been very pleased by consumer and retailer response to these new products, which are performing well in-market.

You May Also Like