ExxonMobil, Ternova, and CPAI worked with Nestlé to develop the film, which is used for secondary packaging in Central America.

December 9, 2022

Nestlé is making packaging-sustainability strides in Central America, using collation shrink film with 25% post-consumer recycled (PCR) content developed jointly with its resin and film suppliers.

The new film is the result of Nestlé’s collaboration with resin producer ExxonMobil; film producer Ternova Group; and Channel Prime Alliance International (CPAI), an ExxonMobil-branded distributor and resin supplier in Central America.

Nestlé uses the PCR-containing shrink film to collate milk-powder and flavor-concentrate tins at four processing plants in Central America. The company previously used virgin plastic film for the applications.

“Ternova’s recyclable shrink film allowed us to start moving toward reducing virgin plastic and circular post-consumption plastic packaging,” said Claudia Alvarado, sustainability manager, Nestlé Central America, in a prepared statement.

“This project demonstrates that a circular shrink film is possible in Central America (El Salvador), and with the right partners it can be implemented elsewhere in the world. Our next goal is to include food-grade post-consumer recycled plastic in our primary food packaging,” Alvarado added.

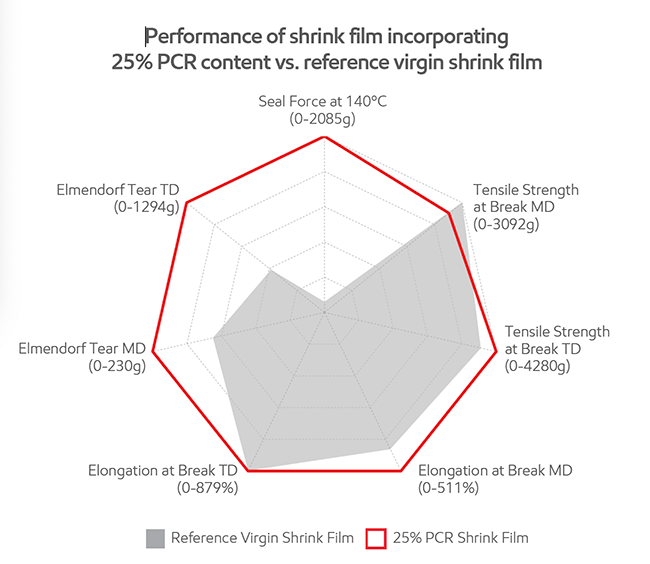

A key technical challenge when incorporating recycled content in shrink films is to establish consistent film performance.

“The issue with using PCR is that it causes more variation in the performance of the collation shrink film,” said Miguel Romano, head of innovation and business development at Ternova.

“Regular resins cannot offset this variation, and, therefore, film quality will falter over time. We saw evidence of this during our trials. Films produced with most commercially available resins caused the packages to loosen and had more incidents of punctures,” Romano added.

Nestlé and its suppliers, working as a team, overcame these problems. ExxonMobil and CPAI provided technical support during development of the film, Ternova designed and created the film using its in-house produced PCR resins, and Nestlé qualified the applications at its packaging sites.

|

For the PCR-containing shrink film, CPAI recommended a combination of ExxonMobil’s Exceed XP 6026 ML and Enable 4002 MC performance polyethylene (PE) resins.

The Exceed XP 6026 ML resin improves the film’s toughness and puncture resistance. This, together with high holding force, improves load protection and pallet stability throughout distribution.

The Enable 4002 MC resin provides high density, which improves holding force, plus a low melt index, which supports shrink performance.

In the final formulation, the two PE resins provide the required combination of toughness and clarity, as well as a balance between elasticity and holding force, for optimal product protection.

The combination ensures that the film performs properly in Nestle’s collating applications while enabling the company to reach its target PCR percentage of 25%.

You May Also Like