Nestlé’s European rollout for cat food showcases a popular packaging format made more sustainable through recyclability.

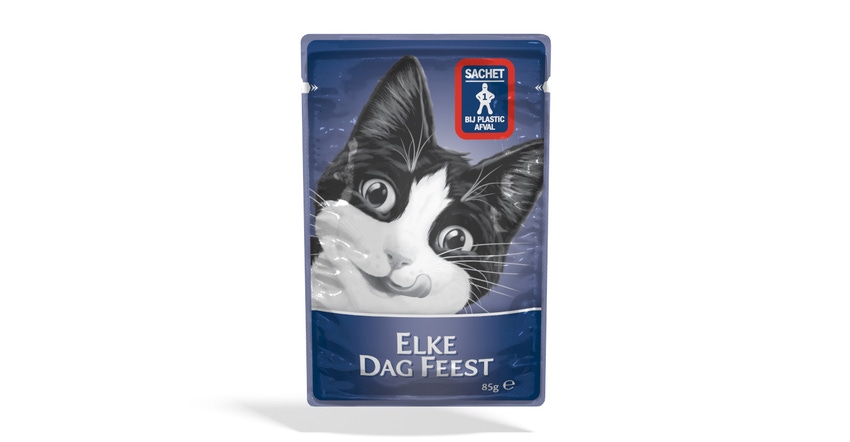

Nestlé’s supplier partner Amcor has conquered a nagging sustainability challenge with the development of a recyclable retort pouch. Cat food will be the first commercial application for the high-barrier AmLite HeatFlex Recyclable pouch. The pet food product, from Nestlé, will launch at retail in the Netherlands this month.

Standard retort pouches are not recyclable, because they are made from mixed materials. The new pouch has overcome that with an oriented polypropylene (OPP)/AmLite barrier/polypropylene (PP) film structure. The printed OPP is the exterior surface of the pouch, and the barrier layer is an extremely thin, transparent coating.

“The AmLite HeatFlex Recyclable pouch is multilayer but meets the CEFLEX guidelines for mono-material packaging, as it’s at least 90% PP-based,” says Michael Zacka, president, Amcor Flexibles Europe, Middle East, and Africa (EMEA).

Amcor, using its Carbon Trust-certified ASSET lifecycle assessment system, calculated that the recyclable retort pouch could achieve a maximum carbon footprint reduction of 60% (assuming 100% recycling of the pouches) vs. a standard retort pouch made from polyethylene terephthalate (PET), aluminum foil, and PP. Tests at Institut cyclos-HTP confirmed that the pouch is recyclable.

Zacka answers questions from Packaging Digest about the development and commercialization of the recyclable retort pouch.

When the recyclable pouch launches, what product and brand will it be used for?

Zacka: The first brand to use AmLite HeatFlex Recyclable is Nestlé for a line of Felix wet cat food. It will appear in stores in the Netherlands in October 2020. This technology will be launched globally into categories including foods, such as ready-meals, pre-cooked soups, sauces, and baby food.

For these products, what type of packaging will the recyclable pouch replace?

Zacka: Retort pouches are a modern alternative to metal cans, as they provide a long product shelf life in a lighter-weight and more resource-efficient format. The new AmLite HeatFlex Recyclable is an upgrade to the existing retort pouch.

Amcor’s AmLite HeatFlex Recyclable replaces previous generations of nonrecyclable retort flexible packaging, which relied on multimaterial combinations — typically PET, aluminium foil, and PP. Although high-performing, this mixed-material structure is not recyclable anywhere in the world today.

Historically, there has been no easy alternative to this multimaterial structure, as the recycling streams for “soft” plastics, such as bags and pouches, currently only accept polyolefins, a type of plastic that has much lower heat resistance than PET.

How did you perform tests for heat resistance, machine performance, and shelf life? Were those tests performed in-house or by an independent organization?

Zacka: The testing for heat resistance, machine performance, and shelf life were done in-house as well as in collaboration with our customer, Nestlé. Each customer’s production lines and product have specific requirements. It was important to work closely with Nestlé to ensure the new material met their requirements for performance and shelf life.

To test for recyclability, we worked with the independent Institut cyclos-HTP and tested the pouch by running it through industrial recycling systems.

Most US curbside recycling programs do not accept flexible packaging. In Europe, are pouches commonly accepted in curbside programs? If not, how will consumers recycle the new pouch?

Zacka: The infrastructure necessary to recycle the AmLite HeatFlex Recyclable pouch already exists in several European countries and is expected to expand. Collection varies by region, and collection for pouches may include curbside recycling or common collection bins where consumers drop off their household recycling.

Do consumers need to do anything to the pouch prior to recycling it?

Zacka: General recycling guidelines are that packaging should be empty of any food product, which is easy with the pouches. The great thing about the packaging is that because it fits into existing recycling infrastructure in the Netherlands, it does not require any changes in consumer behavior to recycle.

What is the barrier coating made of?

Zacka: We have various options for the AmLite transparent barrier coating. In this case, the pouch uses silicon oxide (SiOx). It’s a glass-like material that is applied in a coating as thin as a human hair, which provides a reliable high barrier that does not interfere with recycling.

How do you decorate the recyclable pouches?

Zacka: Most packaging for the retort market uses a chlorine-based matrix, which is, for example, polyvinyl chloride (PVC)-based. For the AmLite HeatFlex Recyclable pouch, we used a new generation of inks, which are chlorine-free.

Going forward, what products besides pet food will we see packaged in the recyclable pouch? When and where?

Zacka: Although we aren’t able to discuss specific customers or products yet, there is market demand for recyclable retort flexible packaging. The AmLite HeatFlex Recyclable solution will expand to other markets and become available for other types of retort foods.

About the Author(s)

You May Also Like