Greenpackt®, a patented, integrated packaging system for sustainable paperboard-based stand-up pouches and rigid packs, claims CO2 reductions 53% less than polypropylene.

February 28, 2023

Sponsored by Fameccanica

Paola Olivieri

Consumer demand for more sustainable packaging continues to push the limits of packaging innovation. One of the latest developments comes in the form of a new solution for single-use detergent packs. Targeting the increasing popularity of simple, green recycled, paperboard materials, a new family of solutions called Greenpackt® has been introduced by Fameccanica that helps make going green as attractive to brand owners and manufacturers as it is to consumers.

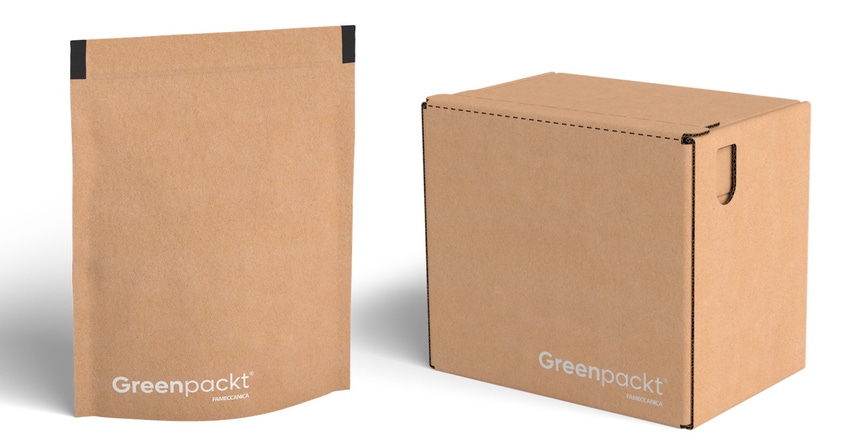

Two types of package formats are offered: Rigid pack and stand-up pouches (shown above), ranging in sizes to accommodate between 15 to 60 single-use packs. They all offer excellent moisture-resistance to prevent against humidity and water vapor. The rigid pack solution also meets a requirement especially critical to this product category: safe child-resistant openings with secure closures in compliance with the standards of AISE, the International Association for Soaps, Detergents, and Maintenance Products.

The stand-up pouches feature reclosable, zippered closures and come in two versions (shown above). The first option produces resealable bags composed of paper and compostable biopolymers. The second option produces resealable bags composed of paper and water-soluble polymers that are harmless to the environment and are designed to avoid possible interference with the recycling process. Several solutions based on these two eco-friendly materials have been developed. Both types of pouches can be customized to meet application needs.

The rigid pack is made from 100% recyclable paper with only corrugated board, recycled fibers, and water barrier paint. The materials are also biodegradable with an estimated 83.4 grams of CO2 carbon emission per pack of 20 single-use units. This is approximately 53% lower than that of polypropylene (PP). The rigid pack is designed for easy storage and shipping and can be customized for size, design, side opening, and the availability of a trapezoidal cross-section.

53% CO2 reduction vs. polypropylene

Considering the rigid pack solution, Greenpackt®'s carbon emission is 53% less than traditional PP package based on the following calculations.

Every year, about 12 million tons of plastic are poured into the ocean globally, threatening the well-being of our terrestrial and marine ecosystems by contaminating natural resources. The average yearly environmental impact of plastic packages amounts to an astonishing 97,000 tons of CO2 equivalence. Of this number, plastic unit dose packages contribute 31,200 tons, or 416 million packs a year.

For a traditional PP package containing 15 detergent packs (weighing 57 grams) the carbon footprint is estimated to have 178.6 grams of CO2 equivalency. In contrast, a Greenpackt® package of 20 packs (weighing 58.7 grams) has a CO2 equivalency of 83.4 grams. This equates to a 53 percent CO2 reduction in carbon footprint.

This CO2 reduction translates into significant real-world benefits. Replacing each new traditionally produced package with one from the Greenpackt® process could generate an amount of oxygen equal to that of four million young trees planted each year, or to the annual energy needs of almost 70,000 consumer households.

Greenpackt® is an integrated machine-product solution involving the entire supply chain, from the selection of raw materials to their processing and beyond. The machinery for producing these innovative packages can produce up to 100 cycles per minute (with a 10% overcapacity). A major benefit is that they integrate the entire packaging process – no separate off-line production of the package itself is required.

Above: Greenpackt® machines for stand-up pouch (left) and rigid pack (right).

Fameccanica is an international group founded in 1975 specialized in Factory Automation which has delivered more than 1,200 machines delivered worldwide; has been granted more than 750 patents; and employs around 700 in Italy, China, and the United States. Fameccanica is part of Angelini Industries, a multi-industry, global Group operating in 21 countries with 5,800 employees.

About the author

Paola Olivieri, Head of Business Development at Fameccanica, responsible for identifying potential areas of business growth and development as well as implementing the company’s digital strategy. She joined the company in 2007 as Project Manager and served roles of successive importance including Project Manager, Project Manager Leader, and Digital Manager. She holds a degree in engineering and an Executive Master in Business Administration from Bologna Business School.

Paola Olivieri, Head of Business Development at Fameccanica, responsible for identifying potential areas of business growth and development as well as implementing the company’s digital strategy. She joined the company in 2007 as Project Manager and served roles of successive importance including Project Manager, Project Manager Leader, and Digital Manager. She holds a degree in engineering and an Executive Master in Business Administration from Bologna Business School.

Paola is passionate about the world of wines and is a Professional Sommelier since 2014.

For more information on Greenpackt® and related solutions, email Fameccanica Communication at [email protected].

You May Also Like