August 28, 2019

Novolex product lines are seamlessly aligned with the ongoing foodservice packaging shift toward sustainable solutions.

Consumers’ appetite for foodservice convenience at restaurants of all types—casual, quick-serve and takeaway—and for catering services continues. According to a report from Markets and Markets, the overall foodservice packaging market is projected to grow from $62.6 billion in 2016 to $84.3 billion by 2021, a CAGR of 5.2% over the period 2017-2022. In offering heat resistance, preventing the growth of microorganisms and helping extend the shelf-life of the food products, the packaging is designed to maintaining the hygiene, quality, and safety of food products at an economical price.

A key trend is the increase in regulations to ensure that the raw materials used are recyclable, such as plastic, paper and paperboard, and cellulose, the study reports, noting that the challenge is that these sustainable materials are often higher in cost higher than their non-biodegradable counterparts.

Packaging supplier Novolex is at the center of this dynamic and increasingly eco-sensitive market. The company’s Adrianne Tipton, Ph.D., vice president of innovation, is a plastic and paper industry veteran with more than 20 years’ experience in R&D. Tipton serves as a guide through a selection of the company’s portfolio that encompasses recyclable and compostable options in paper- and plastic-based packaging.

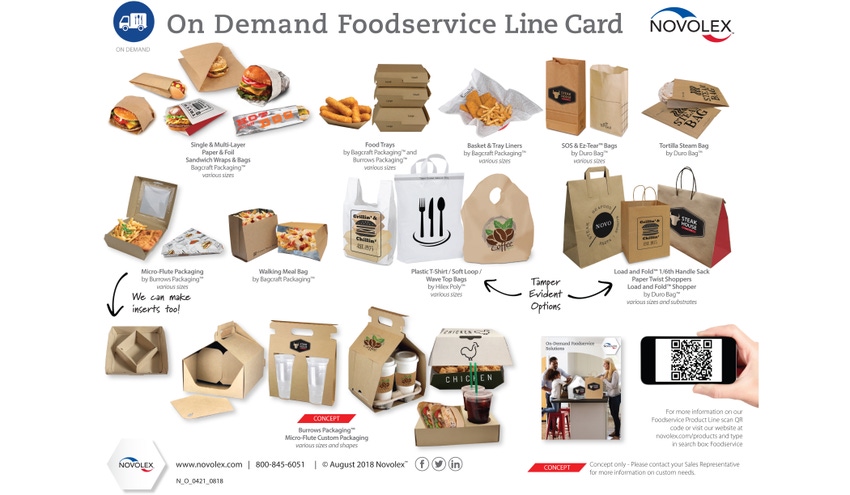

First up is a pair of fresh solutions featuring a tamper-evident carryout bag.

___________________________________________________________________________________

A whole lot of food for thought for packaging will be found at PackEx Toronto June 4-6, 2019, where innovative ideas in containers and design, the latest machinery and automation solutions and free education at Centre Stage will be available. For more information, visit PackEx Toronto. ___________________________________________________________________________________

Load & Fold and Load & Seal Tamper Evident Home Delivery Bags

Description In working toward improved prepared and grocery food delivery for third-party delivery services, convenience stores, grocery stores and quick and limited-serve restaurants, Novolex developed products to keep food safe in transport and preserve food quality, while also reducing the amount of waste associated with shipping and handling. The recyclable plastic bags are designed with tamper-evident closures for food safety while maintaining heat and food freshness and integrity.

When introduced Load & Fold in 2018, Load & Seal in 2019

Materials/structure The substrate is customer-dependent for a choice of plastic or white or kraft paper.

Status There have been extensive trials and interest for both products in this line. These are in test with several large- and medium-size foodservice and retail customers. Novolex is also receiving interest from many global customers that request pricing quotes and trials.

Next: Bagasse as a food packaging source…

Eco-Products

Description Compostable and post-consumer recycled content foodservice packaging, including cups, plates, bowls, clamshells, cutlery, and more. All Eco-Products items are made with renewable resources or post-consumer recycled content, each with their own environmental benefits. Compostable foodservice packaging is made from renewable resources and can help divert waste from landfills because it allows the consumer to put their packaging and food scraps into one bin – the compost bin (where commercial composting infrastructure exists). The use of post-consumer recycled content diverts materials from landfills upstream and uses them to create new products, thereby giving these materials another life. In addition to selling foodservice packaging, Eco-Products also provides marketing and sustainability services to help foodservice operators implement composting and recycling programs, understand their environmental impacts, and incorporate meaningful environmental messaging into their brand.

Two lines of products are available:

GreenStripe products are made with renewable resources and most are commercially compostable. This line includes the newly launched Vanguard line of molded fiber products. Vanguard items are designed to meet updated requirements of the Biodegradable Product Institute for compostability certification that will go into effect on January 1, 2020.

BlueStripe products are made with post-consumer recycled content, though not all of these materials can be recycled throughout the U.S.

Materials/structure GreenStripe materials include plant-based polylactic acid (PLA), paper, and molded fiber, such as sugarcane. The Vanguard line is made of sugarcane (aka bagasse). The vast majority of GreenStripe products can be composted at commercial composting facilities and returned to soil, instead of the landfill. BlueStripe items are made of post-consumer paper fiber, polystyrene (rPS), or PET plastic (rPET).

When introduced GreenStripe 2007, BlueStripe 2011, Vanguard 2019

Status Vanguard water- and grease-resistant molded fiber plates and containers are microwavable, suitable for hot and cold products, and are made from sugarcane. Vanguard was introduced in April 2019. Marketing manager Sarah Martinez tells Packaging Digest that what distinguishes Vanguard is that it is designed to meet BPI’s forthcoming requirements for compostability. The Eco-Products Vanguard line uses a proprietary alternative to traditional grease resistance additives, that is not based on fluorinated chemistry and is accepted in the FDA Inventory of Effective Food Contact Substance Notifications. All Eco-Products items are permitted for use in food-contact materials, per FDA requirements.

Available in a limited release, the initial Vanguard line includes a 10-inch round plate, a three-compartment 10-inch plate, a 9-inch single-compartment clamshell and a three-compartment 9-inch clamshell. A select group of customers is currently running trials. More products will be added soon, including bowls and other sizes of plates and clamshells.

For more information, visit the Eco-Products website.

Next: No-foil sandwich wrap options

Dubl-Shield

Description Fully-recyclable food wrap and bags replace aluminum foil used to wrap burgers and sandwiches. Dubl-Shield was developed in response to demand for a recyclable foil alternative. The Novolex R&D team conducted multiple tests to find the right adhesive and product combination that maintains food integrity with the right balance of moisture absorption and heat retention.

Materials/structure Dual-ply paper laminate.

When introduced 2015.

Status Interest in recycled paper and recyclable products is very high among customers.

Next is a bonus of two non-foodservice options worth noting.

Eco-Blend (left above) and Ultra-Post (right) T-shirt style bags

Development of post-consumer content in plastic carry out bags and can liners has been a focus of the Novolex R&D Team; Eco-Blend and Ultra-Post T-shirt style bags are two notable product lines in this area. Novolex also has the Bag-2-Bag program in which more than 30 million pounds of t-shirt bags are collected and reprocessed as part of closed loop and circular economy initiatives.

Materials and structure Ultra-Post contains 40% post-consumer recycled content and is available as 2.25-mil polyethylene.

Introduced 2016

Status/interest Ultra-Post has been used by many medium and large grocery chains in California. This product is focused on the California market, and Novolex sales continue to grow in this area.

Also, Novolex’s recycling plant works with bag manufacturing plants throughout the region to reprocess plastic scrap from their production lines for the Bag-2-Bag program. The company reports that it also uses post-consumer recycled content from various vendors and customers. For more about Bag-2-Bag, read Novolex Bag-2-Bag System closes loop for plastic bags, published April 2019 by sister publication PlasticsToday.

For more information, visit Novolex.

___________________________________________________________________________________

Much food for thought for packaging will be found at PackEx Toronto June 4-6, 2019, where innovative ideas in containers and design, the latest machinery and automation solutions and free education at Centre Stage will be available. For more information, visit PackEx Toronto. ___________________________________________________________________________________

You May Also Like