July 10, 2014

Over the past decade, sustainability across industries has evolved and grown in importance. Most organizations that once felt it was something they needed to do to meet their social, legal and regulatory responsibilities, today consider improving sustainability of their supply chain as a strategic area of focus, and the packaging industry is no exception to this trend. In fact, the industry has received greater interest from both consumers and stakeholders alike, due to its high visibility.

This article focuses on sustainability issues throughout various packaging formats and explains the importance and necessity of sustainability, as well as the ways packaging professionals go about achieving it.

The brand equation

What drives sustainability in the packaging industry and how does it impact decisions/strategies of brands?

Consumer preference is a major driver of sustainable packaging. This is especially true for companies operating in the consumer packaged goods (CPG) market. Packaging is a critical component which helps communicate the brand’s image and identity. When designed properly, packaging is an effective tool to differentiate their product, build brand loyalty and to reach out to new consumers.

As global awareness on sustainability grows, more consumers are looking for additional information on environmental impact of their packages and prefer packages that offer clear and well-defined environmental benefits. In a survey conducted by Cone Communications, more than 80 percent of the respondents claim that sustainability is important for their purchase decision and would like the package to define the right way to use the product and dispose of it. Now that is a reliable number that shows sustainability is a serious purchasing decision driver and game changer.

Packaging is being effectively used as a communication strategy to convey the sustainability message to the consumers. This is not only informative but has the capability to influence the purchase decision.

Sustainability initiatives of a company directly affect its brand image. Also, sustainable packaging can act as a differentiator in a tough marketplace and enhance the company’s reputation. Surveys conducted have shown that sustainability is major concern for CPG players when compared to other industries (60 percent of CPG companies consider sustainability as a major factor when compared to 40 percent for other industries). Companies will have to change their packaging designs as more and more consumers begin to see the value offered by sustainable packaging.

Major fast-moving consumer goods (FMCG) companies have well defined sustainability goals for packaging materials. For example some of the 2020 targets set by Unilever for improving the sustainability of its packages include reducing packaging weight by a third, maximizing recycled content in their packages, and improving the recycling and recovery rates by 5 percent by 2015 and by 15 percent by 2020, in their top 14 countries of operations.

As of 2013, Unilever’s achievements in this regard include 11 percent weight reduction per consumer use, a 7 percent increase in recycling and recovery rates, and use of 3,204 tons of post-consumer recycled materials.

Suppliers who can help brand owners accomplish their sustainability targets will be given preference when considered for sourcing. Further, suppliers who have proactively invested in supporting sustainability measures will find themselves with better business opportunities when compared to their peers.

Regulatory concerns

Environmental sustainability and its regulations are a major concern for governments.

Many regulations already exist for the manufacture and use of packaging products. Regulations are becoming increasingly demanding which ban the use of certain materials and can also influence the markets. For example, the New York City Council has passed a ban on polystyrene foam food containers, which will go into effect July 1, 2015.

Regulations can also affect the weight of the packaging materials used. The Canadian province of Ontario has set the maximum weight of 750ml wine bottles at 420 grams. Heavier bottles are being penalized. Government regulations that subsidize or provide tax benefits to certain packaging types are likely to see an increase in adoption rate.

Does it make cents?

Cost, cost, cost. Everyone wants a good deal. How does sustainability fit into the equation?

Environmental sustainability and profitability of a company can go hand in hand. For instance, during the economic downturn, consumers were not willing to spend more and packaging companies were pushed to reduce costs. During this time, though sustainability was a consideration, cost was the primary decision maker for most companies. This meant that innovations that reduced costs while improving sustainability gained prominence. As more companies begin adopting these innovations, competitors, too, were forced to initiate sustainability measures of their own.

This concept is true throughout various end use industries and in various packaging formats. Take the films category in the flexible packaging industry for example. Innovation is being driven both on sustainability and cost fronts so as to bring out the best package which can meet market's needs.

One of the major packaging providers, Mondi Packaging (with revenues of US$5.8 billion) has recently come out with a film named PreFoamPack, which it showcased at the German trade fair FachPack in September 2013. This multilayer co-extruded film with micro-cellular expanded cellular layer reduces the weight while maintaining resistance properties and thickness. The company claims that the raw material usage is reduced by almost 20 percent, which will give significant cost savings as well as sustainability advantages.

For a procurement manager or any buyer of packaging supplies, the decision falls in the area of right supplier selection. Most of the companies have stringent sustainability targets that they have to meet; however, finding the right balance between cost benefits and the environmental impact is of paramount importance. The decision needs to be considered based on the past experience of the supplier in terms of innovation and the current success of the same in maintaining a good sustainability score.

Weighing pros and cons

Where and how is sustainability achieved today?

Down-gauging or reducing weight--which helps in reducing the input costs and environmental impact--is an important trend noticeable in the industry. Further gains are obtained when one considers the reduced transportation costs and carbon footprint in the downstream supply chain. This trend is notable in all corners of the world--even in emerging markets.

However, it is easier said than done, especially in industries such as Beer and Prestige Cosmetics, where the weight of a glass bottle, for example, acts as favorable consumer perception and reducing weight may result in lost sales.

In areas such as FMCG, packaged drinking water, FBT and CPG where products and their packaging formats are fairly standard, reducing basis weight may be the simplest way to achieve sustainability as well as cost targets. But in such situations, the procurement team has to exercise caution, as the amount of raw material used in a package will not only reduce the thickness of the package, but may also affect the shelf life of the product. This is especially true if the product packaged inside is a perishable product such as juices.

Another major initiative from the supplier’s side has been to reduce and recycle waste generated. Some innovations have also focused on finding new applications for the generated waste, when recycling is not feasible. For example, U.K.-based paper manufacturer James Cropper has developed a technology to turn shells of cocoa beans into paper.

Companies are also trying to increase the amount of recycled content in their packages. RPET based containers have been developed that can contain up to 100 percent recycled content. Solo, an American packaging provider, has introduced the Bare RPET deli container, which contains 20 percent recycled content.

Changing the packaging material or material substitution can significantly reduce the environmental impact. Standard materials are being replaced with non-toxic, lower weight, biodegradable, reusable and recyclable alternatives. The industry has seen a shift in the consumer packaging industry where PVC (chlorine based) is being replaced with PET. Bio-plastics are growing significantly to the increase in demand for sustainable solutions with a growth rate of more than 20 percent and their production is expected to increase from 1.39 million tons in 2012 to 6.18 million tons by 2017.

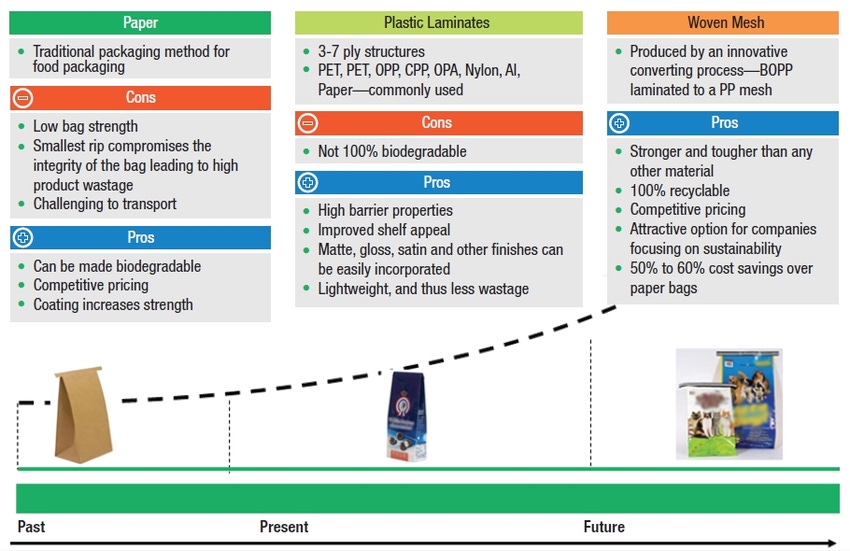

We’ve also seen significant movement in the food bags segment towards sustainability.

For any procurement organization, the main decision related to packaging sustainability will revolve around these five major areas.

1. Source: Where exactly do we need to source the raw material?

2. Process of manufacturing—and how sustainable is manufacturing itself?

3. Material usage—what material is being used in the package and how is the consumer using the package?

4. Distribution—how to distribute the products and how sustainable is the distribution process?

5. Tail end of the life cycle—what happens to the package when its use has been completed? Can it be recycled or does it go to waste?

The most sustainable packaging option is not as simple as using recyclable or renewable materials or choosing the option that weighs the least. Polylactic acid (PLA), a common bio-plastic used to manufacture bottles, is made from corn and other renewable resources. However, when we consider its current end of life handling processes, its sustainability advantages are significantly reduced.

Any package has to be evaluated across its entire life cycle: from sourcing raw materials to recycling, recovery or disposal. The design and development of packaging often involves sustainability trade-offs. Procurement organizations need to incorporate a total life-cycle approach for the packaging required and need to identify where in the life cycle they can incorporate sustainability options.

Sustainability is the need of the hour as illustrated by the various industry cases and cannot be ignored. And as the saying goes, “necessity will be the mother of innovation”.

Bharath Satya Y is a Research Analyst with Beroe Inc., a global provider of customized procurement services specializing in sourcing, supply chain visibility, financial risk analysis and environmental impact to Fortune 500 organizations. He specializes in tracking various rigid packaging categories, including containers, closures and parenteral packaging. Satya Y earned his degree in Mechanical Engineering from the Birla Institute of Technology and Science (Pilani). He can be reached at [email protected]

About the Author(s)

You May Also Like