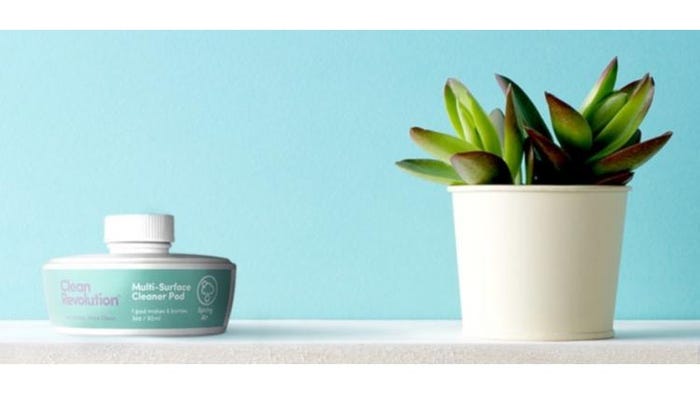

A sustainable-packaging collaboration between Amazon and Replenish has borne fruit in the form of Amazon’s Clean Revolution cleaning products. Amazon uses the new Replenish 3.0 packaging design for its Clean Revolution line, with Replenish acting as a private-label supplier.

Like earlier iterations of the Replenish Refill System, version 3.0 comprises a reusable bottle and refill pods filled with product concentrate. Each (filled) pod weighs about 4 ounces and holds enough concentrate to make six bottles of product. Amazon uses unbleached cloth bags with drawstrings as the secondary packaging for the pods and reusable bottles.

To use Clean Revolution products, consumers screw a refill pod into the bottle’s base, invert the combined package and press the bottom of the pod to release concentrate into the bottle’s built-in measuring cup. Turning the package upright, the consumer removes the sprayer/dispenser and fills the bottle with tap water to dilute the concentrate.

For Amazon and its customers, Replenish 3.0 not only encourages environmental responsibility but also reduces shipping costs. “Focusing on the ability of a reusable, concentrate-friendly platform to dramatically reduce shipping costs in ecommerce is a big deal,” says Jason Foster, Replenish founder and chief reuser. At the same time, Amazon is “tapping into the reuse movement, which is just now starting.”

Replenish sells its own CleanPath brand of home-cleaning products and foaming hand soap, also in the Replenish Refill System, online. Consumers buying the CleanPath Replenish 3.0 system can customize their product and package, choosing from multiple options for fragrance, bottle color and trim color.

Consumers can even upload digital images to be printed on their bottles. “We print directly on the bottle and can do single bottles up to tens of thousands,” Foster says. “It’s a digital printer that has the highest resolution in the industry and can print on curved surfaces.”

He adds, “We offer printing directly on the bottle for CleanPath only at this time, to showcase the capability, but we can of course offer that to any brand or retailer for products that will be powered by Replenish.”

Foster answers some questions from Packaging Digest about the Replenish Refill System, Replenish 3.0 and Amazon’s Clean Revolution products.

Please explain the differences between Replenish 2.0 and 3.0, and the reasons for these changes.

Foster: With Replenish 3.0, we shifted the platform to be completely modular and eliminated much of the ultrasonic welding and injection molding used in manufacturing Replenish 2.0. This shift in architecture not only reduced costs but allowed us to offer top-to-bottom customization, allowing brands and consumers to choose different shapes, colors, materials and bottle or refill-pod sizes. If your favorite color is yellow, you can make a yellow bottle! The goal is to offer products that reflect your personal taste and home, not the limits of a retail shelf.

Also, this move to enable full customization allows brands and retailers to easily customize the Replenish platform to fit their own brand aesthetic and create more differentiation in the marketplace.

Our mission at Replenish is to eliminate one billion plastic bottles from ever reaching the land, ocean or air—reusable, concentrate-friendly packaging can get us there. If you provide consumers with a durable, more attractive product that they feel some affinity towards, they are going to reuse it. We can break the endless cycle of disposability if we build purpose and meaning into consumer products again.

Who manufactures the Replenish Refill System?

Foster: We manufacture the platform ourselves in Aurora, CO, with the help of a network of amazing suppliers. One in particular is our blow-molding supplier GoRight Plastics, Printing, and Logistics. They can do anything and have resources I have never before found under one roof.

When did Replenish 3.0 launch?

Foster: During the second half of 2018, but we will continue to innovate and roll out new features and capabilities in 2019.

What is the printing technology used?

Foster: The Kammann CNC 2250 no-contact Hybrid Digital printer.

How durable are the graphics?

Foster: Durability of the ink is excellent—easily 300-plus dish washings, with excellent chemical resistance and scratch resistance as well.

What plastics are the Replenish 3.0 components made from?

Foster: Replenish 3.0 is fully customizable and can be made with almost any resin, including post-consumer recycled content. The only requirement is to have some clarity in the upper bottle so consumers can see the measuring cup during mixing.

In one version of Replenish being sold today, the reusable bottle is made with Eastman Chemical’s Tritan copolyester resin, while the base is polypropylene (PP), the measuring cup is made from silicone and the refill pods are made with low-density polyethylene (LDPE). But again, there are lots of options from a material standpoint.

Are these plastics recyclable?

Foster: Yes, all components are recyclable, since the bottle can be disassembled by the user. However, we all know the structural issues facing recycling right now, and our message at Replenish is: Don’t forget about the other two Rs—reduce and reuse. Our hope is the last R can recover from the mistakes of the last 30 years, but it’s not going to save us from the disposable plastic tomb modern society is burying itself in.

When did Amazon introduce the Clean Revolution products? What’s included in the line?

Foster: Our collaboration with Amazon just started in February [2019] with the introduction of the Clean Revolution line of cleaning products, a private-label brand created under the Amazon Accelerator Program. The eco-friendly cleaning line consists of a powerful Multi-Surface Cleaner and a luxurious Foaming Hand Soap that sell for about $1.50 a bottle, which is about 50% less than competing eco-friendly brands. More products are in the pipeline, as well.

What benefits does Replenish 3.0 offer ecommerce brands?

Foster: Most of the products we buy are 90% water, which is especially true in cleaning products. By designing a reusable, concentrate-friendly platform, consumers can add water at the point of consumption (the home) which eliminates the bulk and weight across the entire supply chain and in shipping to the home. Why ship 5 pounds of cleaner when you can ship the equivalent in 4 ounces? It’s a stair-step reduction in manufacturing and shipping costs, but a massive leap towards a sustainable circular economy by cutting plastic, carbon emissions and energy usage by 90%.

Bulk and weight are the real enemies in modern-day retail. It kills ecommerce profitability, and it’s the biggest source of waste. It’s time to sell consumers more of what they need and less of what they don’t.

Our hope is Clean Revolution can be a lighthouse that demonstrates all those advantages, especially at Amazon, and that helps change how consumer products are designed and sold in this new era of ecommerce and producer responsibility.

Could the Replenish system be used for other types of products?

Foster: The Replenish platform can be used across multiple product categories, like beauty, personal care, beverage, pet, garden, and industrial and household cleaning.

Are any other brand owners using the Replenish system?

Foster: We will be making some exciting announcements about new brands that will be using the Replenish platform soon.

********************************************************************************

EastPack 2019 (June 11-13) is the region's premier packaging event connecting professionals from companies like PepsiCo, Pepperidge Farms and Mars with suppliers offering the latest packaging technologies, including a range of automation solutions, from semi-automatic equipment to sophisticated "smart" systems. Register to attend today!

About the Author(s)

You May Also Like