April 30, 2020

The future promises to be bright for the paper and board industry. According to research agency Smithers Pira, based on current trends, the sector will experience a period of sustained growth of up to 6 percent annually through 2017. This will result in a global market of more than 30 million tons with an approximate value of $70 billion.

What this means is that the demand for food contact paper and board will be nearly 7.5 million tons higher than in 2012—offering a lucrative opportunity, especially for a paper and board industry, which is on the hunt for new opportunities.

The huge growth in food packaging demand—tied to population growth and the growing middle classes in emerging markets—has had a positive impact on the paper industry already, with a shift in the industry away from paper and board for print media toward specialty grade products, such as food contact paper and board. As a material type, paper and board is a popular material for food contact use. Indeed, the latest inventions in barrier technology position it to be the material of choice in many packaging applications.

Challenges

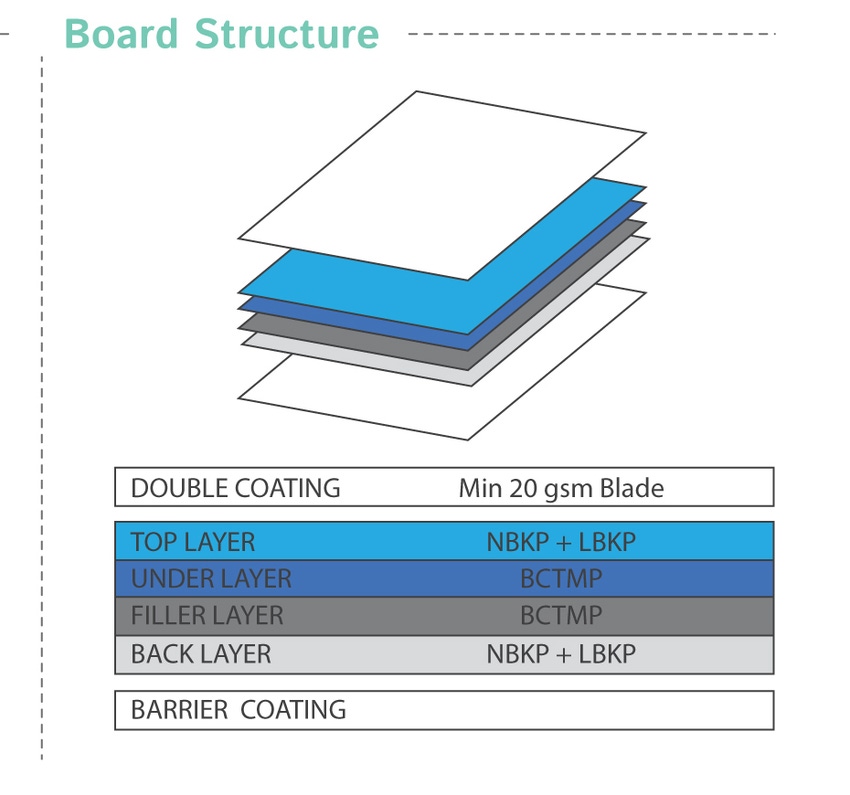

There are challenges. Paper and board only works safely and effectively in a food contact role with a barrier coating of some form. Traditionally, this has usually been a paraffin wax coating where grease resistance is required, or when full oxygen and liquid barriers are required—such as in a juice carton or coffee cup.

Plastic-derived food contact barriers are also essential in enabling heat-sealing, a vital requirement of many packaging formats and designs. These traditional barrier coatings perform well. While the use of a traditional barrier coating involves the use of a non-renewable material, the quantities involved are miniscule, and the latest advances in accurate coating application technologies reduce their use even further.

However, the main issue with barrier coatings is not the use of a non-renewable material, but the impact on end-of-life: barrier-coated boards and papers tend to require particular recycling technologies to enable the separation of materials, such as optical sortation. In particular, as a result of insufficient infrastructure and available technology, this is an issue in emerging markets, which is also where demand will be strongest in the years ahead.

Bioplastics vs water-based coatings

For this reason, there’s been a concentrated focus in recent years on developing new barrier technology that is either renewably sourced, readily recyclable, biodegradable or all three. Bioplastic-based technology is a huge growth sector. They have advanced to the extent that they can rival traditional plastics in functional terms—just look at Coca-Cola’s Plant-Bottle as an example.

Bioplastic barrier technology does, however, face some challenges. To begin with, confusion over what terminology best describes the technology is holding back with brand owners as they wrestle with questions. Are we talking renewable? Biodegradable?

Additionally, bioplastics can confuse consumers. Such questions include: Should they be separated? Can they be recycled? Can they be put in compost?

Finally, there’s the lifecycle issue, with first generation bioplastics in particular: Is the feedstock used for production displacing food intended for human consumption? What’s the climate impact?

Luckily, on the question of lifecycle, bioplastic technology is advancing to the point where it will soon be making use of waste materials as a feedstock. In the pulp and paper industry especially, work is currently underway to determine how lignin, a natural by-product of the pulping process, could be used as a feedstock.

A complimentary approach is a move towards water-based coatings. The use of a water base means that the coating can be readily removed in recycling, composted in a municipal program or, in the worst case, the product will decompose slowly in a landfill (but more rapidly than plastic). The introduction of water-based coatings is especially important for product applications where complete liquid and oxygen barrier technology is not required, such as in the fast-food service sector where packaging is high volume and often misses recycling streams.

The future of paper and board

Moving forward, we’ll likely see continued development of bioplastics as a barrier coating. The issue now is not technology or functionality, but comparative costs and the type and quantities of feedstock consumed.

Alternatively, the industry will see increasing use of water-based coatings, especially for products that only require a grease-barrier. This technology will make paper and board become even more competitive. It competes well with alternative materials today in packaging efficiency and lifecycle terms but, with tomorrow’s barrier technology, paper and board could potentially be the material of choice in a lot of packaging solutions.

About the Author(s)

You May Also Like