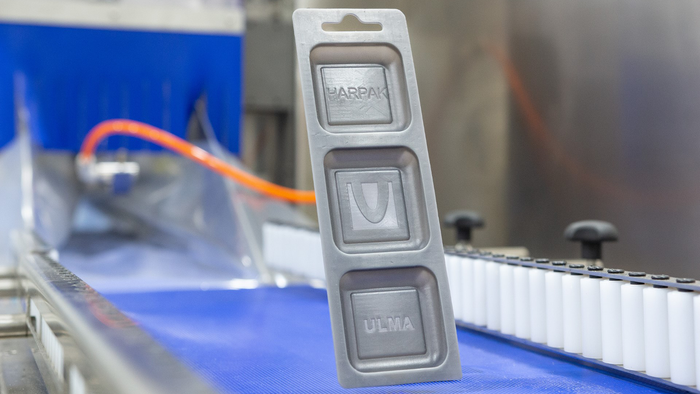

Digital Printing

Labelexpo Americas labeling trends

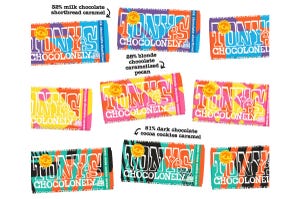

Packaging Design

Package Decorating Trends on DisplayPackage Decorating Trends on Display

A powerful return of a certain printing technology is one of many reasons to make time to visit Labelexpo Americas this year.

Sign up for the Packaging Digest News & Insights newsletter.