June 16, 2015

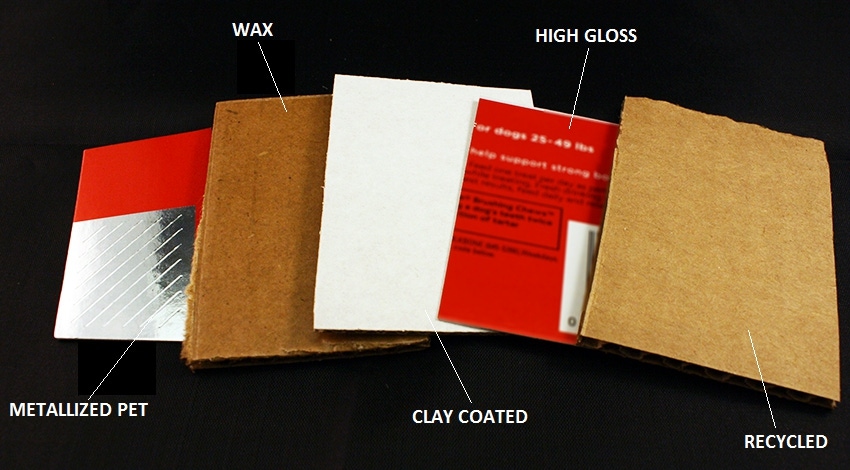

The food packaging industry is home to a variety of packaging, from high glosses that boost shelf appeal to wax boxes that increase functionality. While these unique packaging materials offer a competitive edge in the food industry, they are much more difficult to adhere to and often require specialized adhesives.

Without the right adhesive, you may face pop-opens and other sealing failures, increasing the amount of money and time spent on rework and scrap. By working with their adhesive suppliers, adhesive users can ensure they are using the right product for their food packaging application.

Here are four different types of hard-to-bond paper stocks you might be using for your food packaging, and tips on how you can get better bonds.

1. Wax coatings or wax impregnated

On a warm summer day, many of us enjoy grilling out on the patio and eating a delicious meal with friends and family. It’s not often we consider the way that these foods are shipped and safely arrive at the grocery store for us to purchase.

Poultry, seafood, produce and other perishable food items can get messy during shipping, which is why these products require a special packaging solution to ensure they safely reach their destination. Boxes coated or impregnated with wax are commonly used for these types of foods.

Wax is curtain coated or impregnated into various paper stocks to act as a moisture barrier between the paper fibers and food product. In curtain coated boxes, the wax is concentrated only on the surface of the paper stock, making it difficult for an adhesive to penetrate to the fibers and form a bond.

Wax-impregnated boxes contain wax throughout their fibers. Although these boxes have a higher wax content, the wax is not as concentrated on the top layer, making it slightly easier to bond.

For these types of packaging, we would recommend an adhesive with a long open time, enabling it to penetrate through the wax and form a full fiber-tearing bond.

2. Recycled content

Did you know that corrugated is the most-recycled packaging material on earth? In fact, the average corrugated box consists of 46% recycled fiber.

Just about every product under the sun is shipped using corrugated packaging. It’s rare to find corrugated that isn’t recycled, especially with the prominence of sustainable packaging. Although good for the environment, recycled fibers are more difficult to bond than virgin.

Recycled corrugated is manufactured by breaking down previously used paper and corrugated into pulp, removing contaminants and then reforming into new boxes. The breakdown process means recycled fibers are shorter and more compact than the original fibers, making it harder for adhesives to penetrate and form a good mechanical bond.

Virgin corrugated is less dense due to the longer interwoven fibers allowing adhesive to better wet out and form a bond. Like a tree growing roots in clay versus aerated soil, adhesives can form their “roots” easier on virgin fibers, than on dense recycled fibers.

More commonly, we are seeing adhesive users working closely with their suppliers so that they can pinpoint a specific adhesive—from the many available—to seal their recycled corrugated packaging.

3. High-gloss coatings

Walking through the grocery store aisle, there are many types of packaging—some more appealing than others. You may even be compelled to purchase a product over another due to its packaging. What is it that makes it more appealing?

High gloss, colorful packaging tends to stand out on store shelves and is eye-catching to consumers. Although this type of packaging attracts shoppers and differentiates itself from competitors, its high gloss surface (whether it is polyethylene, polypropylene, metallized or something else) is difficult to bond, often requiring a specialized adhesive.

The smoothness and often low surface energy of a high-gloss carton makes it difficult for adhesives to “wet out” and penetrate the surface. Unlike traditional corrugated adhesion, the hot melt doesn’t bond like a tree forming roots in the ground; rather, the chemical bond behaves more like a magnet. The two materials are attracted to each other because of their chemical make-up, not the mechanical adhesion of a root.

When adhering a high-gloss paper stock, we recommend working closely with your adhesive supplier since this particular application requires a specific hot melt with the ability to form a chemical bond to the surface of these high gloss paper stocks.

4. Clay coatings

Consider which logo would stand out more—the one printed on plain, recycled brown paper stock or the logo on white, clay-coated paper stock? Often the latter, as clay coatings improve brightness and tend to really give any design printed on them that extra “pop,” so that the overall packaging appeals to customers.

Printing on a clay-coated paper stock also reduces the amount of ink used since it does not readily absorb it, unlike an uncoated paper stock. This same concept of resisting absorption is what makes adhesion to this surface difficult. Just as clay-coated paper stock doesn’t absorb ink, it doesn’t allow adhesive to easily penetrate its surface, making it difficult to form a bond.

Adhering clay-coated paper stocks requires a specialized hot melt that has the ability to “wet out” on the surface of the coating. This will allow the adhesive to “bite” through the surface and achieve a good, fiber-tearing bond.

As with all of the hard-to-bond coatings we’ve discussed, we cannot stress enough the importance of working with your adhesive supplier to help you find the right solution that will work for your specific application, whether it is bonding wax boxes, recycled corrugated, high-gloss or clay-coated paper stock. Having a trusting relationship with your adhesive supplier will set the foundation in optimizing your overall packaging process.

Lauren Oliva is the marketing communications specialist for RS Industrial, an adhesive manufacturer and distributor that has been helping customers improve their adhesive processes for more than 22 years. She is passionate about educating audiences as she works with packaging industry experts to provide informative content that is technically focused, yet clear and engaging.

Keep your competitive edge

Hear more about the top issues facing food and beverage packaging departments at the upcoming Global Food & Beverage Packaging Summit (July 7-8; Chicago). Produced by Packaging Digest and its owner UBM Canon, the event consists of two full days of conference sessions, with panel discussions on intelligent packaging and new materials for sustainability, sessions on Innovation and Design for Millennials, presentations on new technologies such as 3D Printing and much more. View the full agenda at fbpackaging.com. When you like what you see, you can register here.

About the Author(s)

You May Also Like