January 30, 2014

“Preshafruit’s unique triangular bottle really sets it apart from other offerings in the juice aisle,” said Beverage Innovation magazine Managing Editor Claire Phoenix. “The bottle immediately gives the product a super-premium feel and the whole presentation, including the sophisticated labelling and unique closure, gives consumers plenty of clues as to just how good these drinks taste. First purchase is pretty much assured through the packaging innovation, repeat purchase is guaranteed through a really great tasting and refreshing drinking experience”.

“Preshafruit’s unique triangular bottle really sets it apart from other offerings in the juice aisle,” said Beverage Innovation magazine Managing Editor Claire Phoenix. “The bottle immediately gives the product a super-premium feel and the whole presentation, including the sophisticated labelling and unique closure, gives consumers plenty of clues as to just how good these drinks taste. First purchase is pretty much assured through the packaging innovation, repeat purchase is guaranteed through a really great tasting and refreshing drinking experience”.

Quite often a fruit juice receives lauding words, but in this case every word is well earned by this exceptional innovation of Preshafood for its fruit juice range which uses a new high pressure processing system and consequently is presented in unique triangular bottles.

Presha fruit juices are made by Australian Donny Boy Fresh Food Company, a food processing company established in 2006 utilising High Pressure Processing (HPP). Its first commercial product, an apricot, peach and apple mix for yoghurt, was the world’s first HPP fruit product used in the dairy industry. And this time it is again the world’s first to use HPP, not heat pasteurisation, to create fruit juices. All juices, (apart from freshly squeezed juices) are heat pasteurised, a process that affects the level of nutrients and taste of the final product.

Presha fruit juices are made by Australian Donny Boy Fresh Food Company, a food processing company established in 2006 utilising High Pressure Processing (HPP). Its first commercial product, an apricot, peach and apple mix for yoghurt, was the world’s first HPP fruit product used in the dairy industry. And this time it is again the world’s first to use HPP, not heat pasteurisation, to create fruit juices. All juices, (apart from freshly squeezed juices) are heat pasteurised, a process that affects the level of nutrients and taste of the final product.

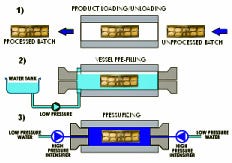

HPP, a technology developed in Europe and used predominantly for meat and  seafood, is a method of food preserving where food is subjected to high pressures (up to 87,000 lbs/sq inch or approx 6,000 kgs/cm2), to achieve microbial inactivation or to alter the food attributes in order to achieve consumer-desired qualities. Most vegetative micro-organisms (bacteria, yeasts and moulds) inactivate at pressures above 60,000 lbs/sq inch. HPP retains food quality, leaves the vitamins and bioactive components unchanged, maintains natural freshness, and extends shelf life.

seafood, is a method of food preserving where food is subjected to high pressures (up to 87,000 lbs/sq inch or approx 6,000 kgs/cm2), to achieve microbial inactivation or to alter the food attributes in order to achieve consumer-desired qualities. Most vegetative micro-organisms (bacteria, yeasts and moulds) inactivate at pressures above 60,000 lbs/sq inch. HPP retains food quality, leaves the vitamins and bioactive components unchanged, maintains natural freshness, and extends shelf life.

In a typical HPP process, the product is packaged in a flexible or semi-rigid container (usually a pouch or plastic bottle) and is loaded into a high pressure chamber filled with water. The water in the chamber is pressurised with a pump, and this pressure is  transmitted through the package onto the food itself. Pressure is applied for a specific time, usually 2 to 5 minutes.

transmitted through the package onto the food itself. Pressure is applied for a specific time, usually 2 to 5 minutes.

The HPP process basically follows the Law of Blaise Pascal which implies that by increasing the pressure at any point in a confined fluid, there is an equal increase at every other point in the container, i.e., any change in pressure applied at any point of the fluid is transmitted undiminished throughout the fluids.

As the pressure is transmitted uniformly (in all directions simultaneously), food retains its shape, even at extreme pressure levels.

To cope with the enormous pressures of HPP, the tube-like pressure vessels are very small. The HPP machine, manufactured by NC Hyperbaric of Spain, for Donny Boy’s Preshafruit has a pressure vessel with a diameter of only 19 cm, consequently requiring the juice bottles to be triangular in order to fit efficiently in the machine’s circular pressure vessel.  This in itself created a unique approach to the packaging as six of the Preshafruit triangle bottles form a hexagon which fits exactly in the circular shape of the pressure chamber, consequently creating a juice bottle as no other in the market.

This in itself created a unique approach to the packaging as six of the Preshafruit triangle bottles form a hexagon which fits exactly in the circular shape of the pressure chamber, consequently creating a juice bottle as no other in the market.

It was up to Design By Pidgeon to complete the design for a highly competitive market and to communicate Preshafruit’s benefits and points of differentiation. The triangular bottle allowed Design By Pidgeon to design three faces on each bottle to communicate the three different messages of the brand’s key story - 100% Australian, pressurised cold, just picked taste. The triangular or wedge shaped bottle allows for an especially effective promotion in the supermarket aisles.

VIP Packaging, a leading plastic and steel packaging solutions provider in Australia and New Zealand, manufactures the unique 350ml PET bottle and closure for Preshafruit juices.

A brilliant packaging innovation.

*

About the Author(s)

You May Also Like