January 29, 2014

If in vino veritas means in wine, there is truth, how a wine is packaged may also reveal a bit of truth about the wine and its vintner. Throughout history, wine bottles have been romanticized, but the capsule covering the cork or closure can speak volumes about a wine's quality, heritage and taste. That's why Turner Road Vintners (TRV), Woodbridge, CA,

|

Above, finished gravure-printed capsules for TRV's Vendange wine label are stacked in slugs that can contain 35 to 50 capsules each. |

which sells and bottles some of the most popular wines in the U.S., has uncorked a luxurious yet high-performing vinyl capsule for its successful wines. The subsidiary of Constellation Brands' Canandaigua Wine Co. markets wine under labels such as Vendange, Nathanson Creek, Talus, Heritage and more. The captivating wine capsules, produced and printed by Maverick Enterprises, have given TRV a significant marketing edge due in part to Klöckner Pentaplast of America's heat-shrinkable polyvinyl chloride material with which they're made.

Vying for tight shelf space, TRV sees the capsules as an important marketing advantage. That edge is vital, with tough competition among varietals. Producing more than 40 million bottles of wine a year, TRV wants its wines to look and taste their absolute best. Good looks are a must for the whole package, from the capsule on down. Opening a wine bottle is when the anticipation and romance begin, says Tim Pletcher, plant manager of capsule converter, Maverick Enterprises.

Maverick, which produces and prints TRV's wine bottle capsules, sees the need for vintners to distinguish every aspect of wine packaging. "One way to do it is with capsules," Pletcher says. Considered the only vertically integrated U.S. supplier to be able to convert, print and form PVC capsules for wine bottles in custom color matches, Maverick produces and prints capsules for some 300 to 400 different wineries, customizing colors to match graphics with the aid of four- and six-color narrow-web gravure presses from CMR S.r.L.

Maverick brings in raw vinyl material in master rolls, then prints, finishes and forms the capsules. But this can't be done with just any raw material, Pletcher says. For TRV's current bottles, Maverick uses Klöckner's Pentaprint® OT Series M145/01 clear and OT M146/19 white and black, transverse-direction-oriented (TDO) heat-shrinkable vinyl in 70- and 75-micron thicknesses, respectively. TRV's capsules are made in 34- and 37.5-mm sizes to accommodate both standard and flange bottle finishes. Maverick prints some of TRV's capsules with metallic color bands, piping and other designs. "Klöckner's films give us the ability to meet rigid specifications for thickness," Pletcher notes. "The printability is the best in the industry."

|

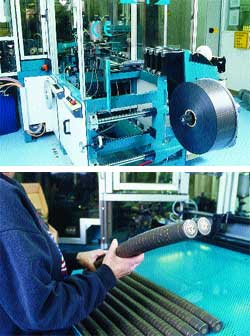

Maverick prints the TRV capsules in two and three colors before they're formed, top, on a German machine. Large master rolls of printed vinyl unwind and travel through the forming stations that wrap the vinyl around a mandrel and heat-seal and cut it into the tube shapes. Capsule tops are also die-cut and embossed in-line. Long sticks or slugs of capsules, above, then drop into a bin at the end of the machine. |

Pentaprint is available in four basic grades: clear, gray-impregnated, black-impregnated or white-impregnated, all of which are used to attain a particular sheen or color. "The substrate choices from Klöckner Pentaplast are fully compatible with our ink system," Pletcher says. "The quality is consistent and no matter what color we use, we see excellent ink adhesion, which is a big boost to our production efficiencies."

The black- and white-impregnated PVC capsule materials are what Maverick uses most in TRV's case, printing them in several different color schemes that correspond to TRV's wine labels. Notes account manager Jon Henderson, "Sometimes we print the PVC in a couple of passes to achieve olive green or copper and gold colors, then we print it, slit it and form the capsules."

Chet Koehn, Maverick's technical director, says the TDO films' shrink characteristics allow the capsules to be applied at low and high speeds on bottling lines. "With Pentaprint's quality and consistency, we can focus more on the custom print colors involved, because the film is nonvariable and performs so well. The superior film quality makes us more efficient, so ultimately, there is less waste. With the opaque, color-impregnated vinyl material, we don't have to put as much ink down."

Henderson tells PD that through experience, his firm has come to know that the more ink applied to a capsule, the more likely it is to fracture when applied to a bottle. "If there are three, four or five layers of ink applied, the capsule can sometimes crack as it's applied to a bottle at great force. With the color-impregnated materials, there is less of a chance of fracturing because the color and opacity are already built in." Rolls of the Pentaprint vinyl arrive at Maverick's converting facility in multiple slit widths, depending on the size of the capsule. Rolls range from 330 to 405 mm (12.9 to 15.9 in.). Henderson says the Pentaprint vinyl exhibits superior seaming ability and gauge tolerance, which allows finished capsules to shrink uniformly around cylindrical shapes when exposed to uniform heat in a heat tunnel.

Attention to detail, color

The capsules are produced in several signature colors to coordinate with the different wine labels and bottle colors. Many of the tops are embossed and printed with ornate designs that signify the brand of wine they cover.

The OT M146/19 film is described as a matte/gloss opaque-colored rigid vinyl that Maverick says achieves a sophisticated look. The capsule for Talus Chardonnay features a black capsule with olive green, antique gold and black accents, all of which mesh nicely with the green grape and gold trim found on the bottle labels. Wines from Nathanson Creek display a copper capsule, printed in a gold/bronze ink with the Nathanson Creek logo and gold/bronze piping that matches the piping on the bottle's front-panel label.

Maverick offers more than 2,000 print colors. All of the inks are custom mixed in-house by the converter's in-house press department, which carefully custom matches and finishes them to TRV's requirements. Proprietary solvent-based inks are formulated for the particular substrate to which colors are applied. Most of TRV's capsules are printed in two or three colors.

Once the capsule designs are finalized and the designs are sized, a technician modifies the artwork to fit it correctly on the capsule. Layouts are approved, and a print cylinder is created. For Nathanson Creek capsules, Maverick uses two print cylinders–one for the gold band and one for the flood coat, or primary background color, which is copper. A stock roller is used for the flood coat, while custom rollers are used for the artwork.

Printing, forming

Printing of the capsules is done while the material is still flat, but embossing of the capsule tops is performed during capsule forming. A master roll of the vinyl unwinds and enters the print stations of either CMR gravure press and is printed three-across with TRV's designs. The rolls rewind before they are finished on one of two Conweb machines that slit them into smaller rolls ranging from 106 to 130 mm (4.17 to 5.11 in.) wide.

|

Color-impregnated TDO vinyl unwinds on an Italian gravure printing press at a facility that generates 1.5 million wine capsules a day. |

The slit, printed rolls are then taken to the capsule formers, Christian Majer machines from Germany, in another area of the plant. Each capsule actually starts out in two pieces–a flat top disc and a bottom "skirt." Thus, the rolls of vinyl are cut again into blanks, with each blank wrapped around a mandrel and heat-sealed into a tube shape. The flat top discs, meanwhile, are embossed and then punched out from a strip of separate material before they're heat-sealed onto the skirts, resulting in a finished capsule. Some of TRV's capsules also feature a built-in teartape, which is also produced at this time. The finished capsules are then nested on sticks holding 35 to 50 capsules each with the help of the machine's collector tube, and are bulk-packed by the thousands into shipping containers and transported to TRV's facility in Woodbridge.

Gravure printing provides luxurious colors, but Henderson and Koehn say it takes a craftsman's skill to operate the presses. Just in case a shade of color starts to differ from specifications, color consistency is controlled by a computerized scanning spectrophotometer from X-Rite to ensure that colors stay true. Explains Koehn, "Attention to color is critical. Consistent color tolerances are extremely important. And, because we use such a quality vinyl, we can adjust so many colors. Shrink-down is also consistent with Klöckner Pentaplast Pentaprint, as is its ability to absorb shock." Henderson and Koehn say that overall for all of its customers, Maverick produces a whopping 1.5 million capsules a day. "We use proprietary agents and other things to give the capsule material a matte or sleek, glossy finish," says Koehn. "That's why we like to print our own material. We've learned how to achieve certain finishes that can't be done by just any printer." He says the entire package has to look perfect–not just the bottle and the label, but the capsule, as well, which can be the first thing people notice when opening a bottle of wine.

Capsule application

The PVC capsules arrive at TRV's winery/bottling facility in long stacks (or slugs) containing 35 to 50 capsules each. After the bottles are filled and corked on two bottling lines that run the 750-mL and 1.5-L bottle sizes, the capsules are applied by a pair of Robino and Galandrino capsule applicators that shoot the capsules on at rates of 225 and 300 bpm, respectively (Robino and Galandrino is represented in the U.S. by fp Packaging, Napa, CA). The capsules are then sealed onto the bottles before they are labeled on Krones equipment. Capsules applied at those rates of speed cannot be brittle, says TRV's senior packaging material specialist, Pablo Lewis. "This is where problems can occur and can become a bottleneck if you don't have the right material. Prior to trying capsules from Maverick, we didn't have much success using vinyl. We tried capsules from their competitors overseas, but no one could do what they do. Maverick produces more than 40 million capsules a year for us. We couldn't get close to achieving the line speeds we needed before we started using their capsules."

|

Slit rolls of printed vinyl unwind on one of two German capsule-forming machines. Blanks of vinyl are cut and wrapped around a mandrel and sealed into a tube shape; top discs are then applied. |

The slugs are fed into a device that basically feeds one capsule after another, machine-gun-style, onto the bottle necks using a claw to hold the remaining slug. As the bottles enter the applicator, a burst of compressed air separates and blows a capsule off the slug and into one of many capsule-holding cups mounted on a device that then rotates above the incoming bottles.

Another burst of air blows the capsule onto the bottle. On the 750-mL line, the bottles then convey through a Secomak heat tunnel that shrinks on the capsules snugly. Bottles running on the 1.5-L line convey around a Robino and Galandrino heat-shrink system, which, within seconds, tightly shrinks the capsules over the larger bottles.

The heat-shrink process is crucial, Pletcher explains, because the heat can cause capsules to wrinkle or even fracture, requiring the machine to be stopped for adjustments. "That would create significant downtime, which translates into inefficiencies," he says. "For a tight seal, the vinyl has to shrink uniformly. We have noticed that Pentaprint vinyl shrinks smoothly and without wrinkles."

Koehn agrees, adding that the vinyl film must shrink in the transverse [horizontal] direction 40 to 42 percent, and only 2 percent vertically, with good impact-resistance to prevent fracturing. "Pentaprint's uniformity enables us to adjust to the many colors being used."

In the wine industry, leadtimes can be short, Lewis points out. Wineries can't always plan bottling schedules and orders for packaging supplies all that far in advance. And, since varietal wines are bottled year 'round, TRV often needs capsules at-the-ready. Says Lewis, "We don't store too many capsules. We may place an order well in advance, but we usually don't get capsules until approximately one week before bottling. However, we may give Maverick short notice for things when we have a special bottling job."

Sums up Lewis, "We're pretty pleased with the capsule material. Fracturing used to plague us, but now, it's virtually nonexistent."

Lewis goes on to say that the black vinyl Maverick uses is nearly flawless, which has helped to raise TRV's efficiencies. And that's always worth raising a glass to toast.

More information is available:

Vinyl capsule film: Klöckner Pentaplast of America, Inc., 540/832-3600. Circle No. 262.

Capsules: Maverick Enterprises, Inc., 707/463-5591. Circle No. 263.

R&G capsule applicators, heat tunnel: fp Packaging, Inc., Fleming Packaging, 707/258-3940. Circle No. 264.

Presses: CMR, S.r.L., 39 02 99 04 53 63. Circle No. 265.

Slitters: Conweb, Inc., 973/808-9787. Circle No. 266.

Capsule formers: Christian Majer Gmbh & Co. KG, 49 7071 948 0. Circle No. 267.

Spectrophotometer: X-Rite, Inc., 616/534-7663. Circle No. 268.

Labelers: Krones, Inc., 414/409-4000. Circle No. 269.

Radiant heat head: Secomak, Ltd., 44 0 20 8952 5566. Circle No. 270.

You May Also Like