AI to Power Package Handling for Spirits Brand

Southern Glazer’s Wine & Spirits steps into the future with Symbotic’s artificial-intelligence-powered warehousing system for improved speed, efficiencies, and 99.99%+ accuracy.

The handling of beverages can be a challenging task due to their weight and awkward bulkiness. Despite these challenges, advancements in technology enable brands to overcome even the most complex situations through remarkable feats of engineering.

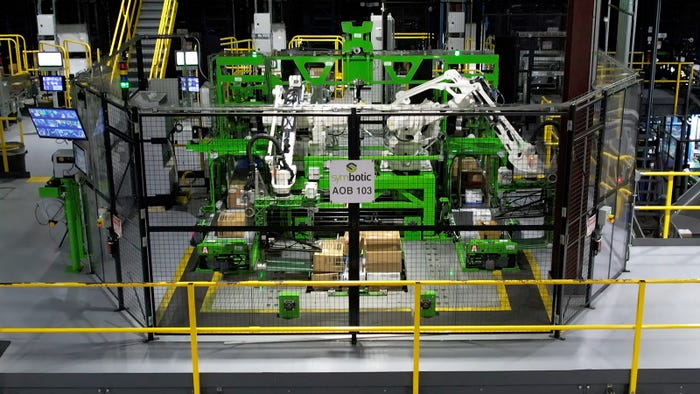

The Symbotic System from Symbotic Inc. is an end-to-end, AI-powered software and robotics warehouse system capable of building mixed-case pallets for dynamic route-stop delivery. The technology enables beverage distribution centers to improve efficiencies and facility safety measures while accurately managing both high velocity and slow-moving inventory, improving fill rates, order accuracy and customer service times, while extending the capacity and useful life of its existing facilities.

The promise and potential of the system prompted Southern Glazer’s Wine & Spirits to forge a partnership for deploying Symbotic’s warehouse automation systems in select Southern Glazer’s distribution centers. The first system will be operational by 2025, which is a first for any brand.

Prior to this, Symbotic’s technology has been used exclusively in retail through the supplier’s partnership with Walmart. The images are from that installation.

AI tech gets products on shelves more quickly.

Mike Dunn, Symbotic’s senior vice president, sales, marketing and product strategy, explains that the ability to build palletized loads of delivery sequence sorted inventory ultimately enables distributors to get products onto shelves more quickly, while also making one of the toughest aspects of supply chain work–material handling–safer and simpler.

“The result is an optimized high-density, mixed-SKU pallet that can be most efficiently delivered to the end customer,” he says. “Modernizing the warehouse allows consumers to get what they need faster and creates benefits for everyone including workers, customers and their local communities.”

SYMBOTIC

The partnership between Southern Glazer’s and Symbotic is “long-term” though both parties declined to disclose the financial value of the partnership.

“We’re confident that our ongoing investments will continue to set Southern Glazer’s service capabilities apart in the marketplace, while enabling us to improve efficiency, as well as enhance skills, opportunities and safety for our employees,” comments Bobby Burg, chief supply chain officer for Southern Glazer’s.

AI benefits versus typical WMS software.

What are the differences between an AI-powered warehouse automation software versus typical warehouse management system (WMS) software?

The Symbotic System integrates with a WMS to drive the entire process, according to Dunn.

“The use of AI-powered software enhances the speed, accuracy and efficiency of warehouse operations, resulting in faster and more effective delivery of goods,” he says. “AI-powered warehouse software drives more efficient tasking and routing for the mobile bots, enables complex business rules for building mixed-SKU pallets and produces data insights and opportunities for further efficiency from the 3 to 6 Terabytes of data per day generated by the system.

AI-powered software can also process incoming pallets, optimize case orientation, transport cases with speed and efficiency and construct high-density pallets for delivery. The streamlined efficiencies hinge on robots equipped with advanced vision and sensing capabilities that work seamlessly together, building optimized mixed-case pallets with industry-leading speed and density.

SYMBOTIC

Near-perfect accuracy for millions of cases.

“These robots have robust machine learning capabilities that continuously enhance the system’s performance and reliability by recognizing patterns and optimizing for operational variations. The advanced vision and sensing technologies on the end-of-arm tools and cameras on board the mobile bots help enhance the system’s reliability and performance, resulting in 99.9999% task accuracy or one error per million cases,” Dunn comments. “Moreover, the handling mechanisms of these robots are highly versatile, which means that they can adapt to a wide range of products, enabling the system to process more products within its unique storage structure without sacrificing density.”

As a result, the system can access any case within the system in less than two minutes to create high-density, mixed-SKU pallets optimized for speed and efficient delivery to the end customer.

“The system is designed with a unique storage structure and dynamic storage algorithm that maximizes the cube of a building and enables 30 to 60% footprint reduction, [freeing] up space for additional capacity, thereby extending the lifespan of existing facilities,” Dunn explains.

The technology is also meant to aid the efficiencies of beverage distributors challenged by SKU proliferation for smaller, more frequent shipments. All products in a company’s inventory are digitized at the point of entry while sophisticated vision systems scan and track every product that moves through the system.

“Because products are stored at the case level by powerful AI-enabled software in a unique storage structure, this enables high-velocity products and long-tail slow movers to be managed with the same robotic efficiency and 99.9999% accuracy, reducing damage and mis-picks in the warehouse,” Dunn concludes.

About the Author(s)

You May Also Like