PHA Biopolymer Coating Makes Noodle Cup Compostable

CJ Biomaterials’ patented polyhydroxyalkanoate (PHA) replaces a polypropylene coating in microwavable food packaging for South Korea’s leading convenience-store chain.

At a Glance

- CJ Biomaterials' PHA technology creates compostable noodle cup coating in South Korea

- The innovative eco-friendly cup reduces plastic waste, integrating PHA biopolymers

- US adoption depends on policy support, waste management, and brand preferences

The lining or coating is a small percentage of a package's material footprint, but it can make all the difference when it comes to its sustainability.

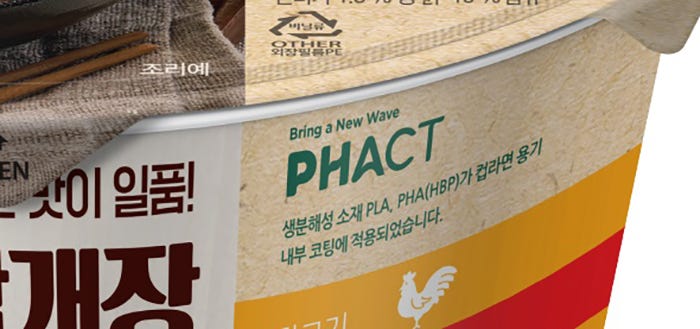

CJ Biomaterials, Inc., a division of South Korea-based CJ CheilJedang and a primary producer of polyhydroxyalkanoate (PHA) biopolymers, revealed its patented PHA technology is used in the production of a new noodle cup sold at South Korea’s leading convenience store chain, CU.

The new, eco-friendly noodle cup is the first of its kind in the country. With CJ Biomaterials’ PHA technology integrated into the cups’ inner coating, the cups are now biodegradable and compostable, reducing the amount of plastic waste entering the environment.

The cup, which is used for two products, just had to put on a new biopolymer coating.

In 2023, CJ Biomaterials developed microwavable paper coating technology by combining its patented PHA with polylactic acid (PLA). The paper coating solution increases bio-based content while reducing its petroleum-based plastic without compromising the functionality and quality of the paper cup. Through CJ Biomaterials’ partnership with CU, the coating technology will be used on the convenience store’s popular New Today’s Chicken Noodle cup packaging.

CJ Biomaterials' PHA is marketed using the brand name PHACT, which stands for PHA + Action, demonstrating the company's commitment to sustainability.

CJ Biomaterials

“Using PHA with PLA can enhance the processibility of PLA by providing flexibility and allowing more stable use across a wide range of temperatures,” says Max Senechal, executive VP and COO at CJ Biomaterials. “It also exhibits good oil-barrier properties, surpassing conventional polypropylene coating while providing a 100% bio-based solution. Through this partnership with CU, we are not only contributing to the creation of eco-friendly packaging, but also demonstrating the practicality and affordability of sustainable alternatives. This marks a significant step toward reducing plastic waste and promoting a greener, more environmentally responsible future."

There’s more in the convenience chain’s future, according to Heidi Lebel, VP of strategic marketing at CJ Biomaterials. “CU is actively exploring new applications to apply this same technology but launch timing has not yet been defined.”

And, as she suggests, “this technology can expand well beyond noodle cups and ramen.”

US forecast for PHA-coated microwavable cups.

This kind of biopolymer-coated microwave cup can be used in the US.

“All ingredients used to make the CU noodle cup coating are food-contact approved in the US,” Lebel says.

The big question: but will it?

“The extrusion paper coating that uses PHA and PLA can be used with almost any microwavable package and offers great barrier resistance,” she responds. “For this reason, it’s difficult to predict the extent to which this will be adopted in the US and globally.”

However, Lebel points to three factors that will determine US adoption of this bio-based packaging:

1. US policy that supports compostable packaging;

2. Waste management infrastructure; and

3. Brand desire to message non-fossil fuel-based alternatives or compostable end-of-life solutions such as biopolymers that are certified compostable.

Derived from nature and produced sustainably, CJ Biomaterials’ PHA biopolymers can be used as building blocks to replace and improve the functional characteristics of a broad range of polymers in the production of finished goods or as starting points for sustainable chemistry. PHAs work well as modifiers to other polymers or biopolymers to increase bio-based content, accelerate biodegradation, and improve the functional properties of resins and finished products. CJ Biomaterials is one of only a handful of companies capable of mass-producing PHA.

CJ Biomaterials continues to expand on the applications of its PHA technology, developing solutions for food and beverage packaging; foodservice ware; fibers and nonwovens; consumer goods; agriculture and horticulture; and 3D printing filament.

Over the past year, the company worked together with Riman Incellderm to create environmentally friendly cosmetic packaging, and collaborated with various companies, including CJ Olive Young, Dongil Platech, Yuhan-Kimberly, Banila Co., and biopolymer manufacturer NatureWorks to broaden the use of PHA in multiple markets and applications. The company also won the German 2023 Red Dot Design Award for the PHA Head-Up Toothbrush, developed in partnership with eco-friendly design specialist, Revelop.

About the Author(s)

You May Also Like