Understanding Continuous Inkjet for Package Coding

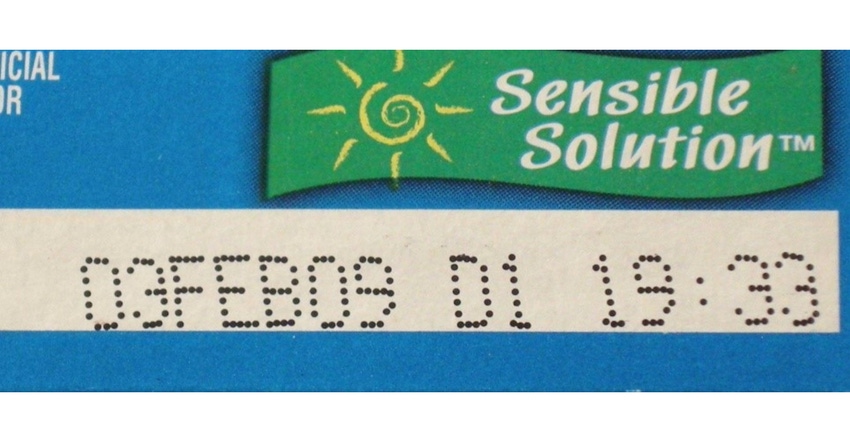

A common package coding technology, continuous inkjet prints ink drops in a grid pattern to create letters, numbers, and images.

September 15, 2023

Inkjet coders are commonly used to print variable information such as lot and date code on packaging. They work with plastic, glass, metal, film, paper, and almost any other packaging material provided the proper ink is used. They can code at speeds up to 2,500 codes per minute.

But do you know how they work?

Let’s look at the most common style, commonly called Continuous Ink Jet or CIJ.

They are called continuous because they shoot a continuous stream of tiny ink droplets. These are directed onto the package in a series of vertical lines as the package moves past a fixed-position printhead. A few applications hold the package stationary and move the printhead. Each line can contain a different number of droplets as needed to form the character.

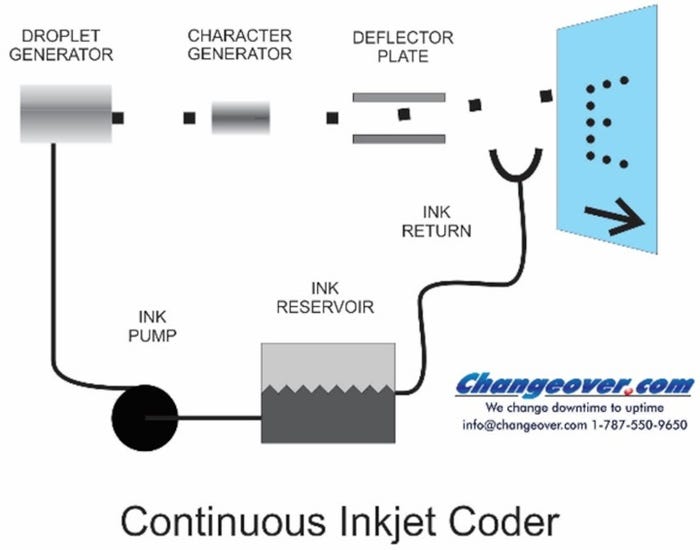

The principle of operation is actually pretty simple. Ink is pumped from a reservoir through a piezoelectric droplet generator. The droplets are shot through a character generator that imparts a static electricity charge to each according to the character being generated and the intended position. A pair of deflector plates uses static electricity to push the droplet up or down. Droplets that are not used are directed to a gutter and returned to the ink reservoir.

The schematic below shows the letter E as a 5X3 matrix. The first column in the grid (at the far right) prints dots 1 and 5. The second prints 1, 3, and 5. The third prints all 5 dots. Inkjets print up to 10X10 matrixes, which provides better character resolution and simple graphics.

CIJ printers have a well-earned reputation for being messy. In recent years there have been many improvements in the technology and this is no longer the case. When you need to print variable information, they are an excellent option.

It’s easy when you know.

Find out more about CIJ and other printers and coders and how they work. It’s all in Chapter 7 of John Henry’s Packaging Machinery Handbook. Other chapters cover inspection, flexible packaging, capping, and all commonly used packaging machinery. The complete table of contents and chapter samples can be found at http://www.packmachbook.com/handbooksample.pdf.

Purchase the Handbook on Amazon at https://amzn.to/3kr4qj7

About the Author(s)

You May Also Like