Sustainability at General Mills: The Inside Story

Hear from an R&D executive on the company’s packaging sustainability strategies, including reducing materials use, switching to more environmentally friendly materials, and building recycling infrastructure.

At a Glance

- Cross-disciplinary team deploys a powerful analytics tool to track packaging sustainability data

- Success stories from Häagen-Dazs, Panier de Yoplait, Annie’s, and Nature Valley show real benefits of innovative change

- On-pack QR code connects consumers to real-time recycling options in their local community

David Chmura, R&D senior manager at General Mills, talked in-depth about the company’s work to reduce the environmental impact of its packaging in his MinnPack 2023 keynote, “Navigating the Path to Packaging Sustainability.”

The keynote was presented in partnership with the Minnesota Chapter of the Institute of Packaging Professionals (IoPP), as part of Informa’s Advanced Manufacturing Minneapolis event. Informa is the parent company of Packaging Digest.

Packaging Digest, Lisa Pierce

Chmura discussed General Mills’ sustainability strategies, as well as its goals and victories. The five strategies are:

• Reducing, reusing, and recycling.

• Innovating with materials.

• Educating.

• Building infrastructure.

• Collaborating with external organizations.

Sustainability goals and teamwork.

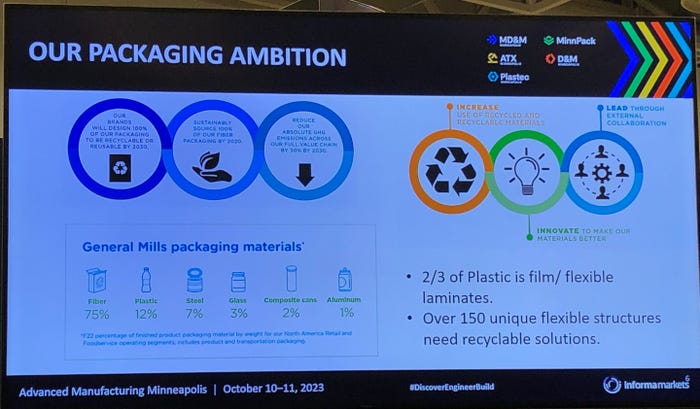

About five years ago, the company reviewed its complex packaging portfolio and set a goal of 100% recyclable or reusable packaging by 2030. Today, “we’re about 92% of the way … towards that ambition of recyclable or reusable,” Chmura said in October 2023.

The starting point for meeting that goal was to create a cross-disciplinary team and deploy a powerful analytics tool to track packaging sustainability data for the company’s 5,000 to 6,000 packaging specifications.

“Trying to manage all that and sort it all out on an Excel spreadsheet was not going to work,” Chmura said. So, the company pulled together a team with expertise in sustainability, data and technology, packaging, R&D, supply chain management, and finance.

Packaging Digest, Lisa Pierce

To track sustainability progress, the team uses a cloud-enabled data analysis and reporting tool loaded with internal data, such as finished product specifications, product volume, and pricing, as well as external data, such as greenhouse gas emissions and lifecycle analysis tools.

Reports from the data-analysis tool enable the team to track data about packaging materials, among other things. “It will tell us everything we need to know about that material. … Is it recyclable? Is it not? What family does that belong in?” Chmura said, explaining, “we grouped the different [sustainability challenges] into what we call ‘families.’”

Reducing, recycling, and circularity.

Chmura used examples of General Mills’ sustainable packaging projects to illustrate the company’s five core strategies.

In an example from the “reduce” category, the company eliminated wooden spoons that had been attached to the underside of the lid on single-serving Häagen-Dazs cups. That small change eliminated 130 million spoons per year in the United Kingdom alone.

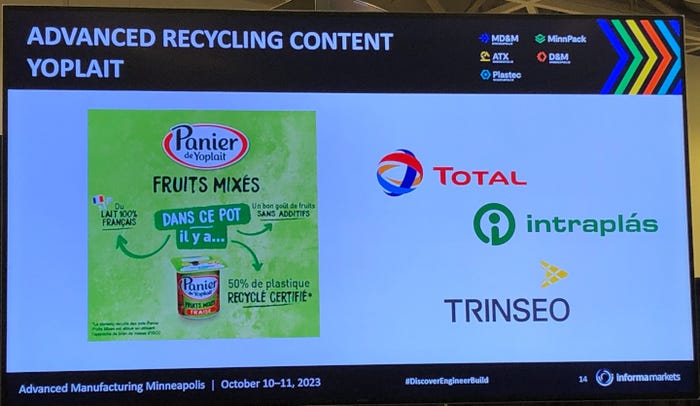

An example of the company’s commitment to recycling and plastics circularity centers on General Mills’ partnership with an advanced recycling company in Europe. The goal was to boost the amount of post-consumer recycled (PCR) polystyrene in form-fill-seal cups used for Panier de Yoplait yogurt.

Packaging Digest, Lisa Pierce

The cups now contain 50% PCR polystyrene. The results were “staggering,” Chmura said, noting that “thousands of tons of polystyrene [were] saved every year.”

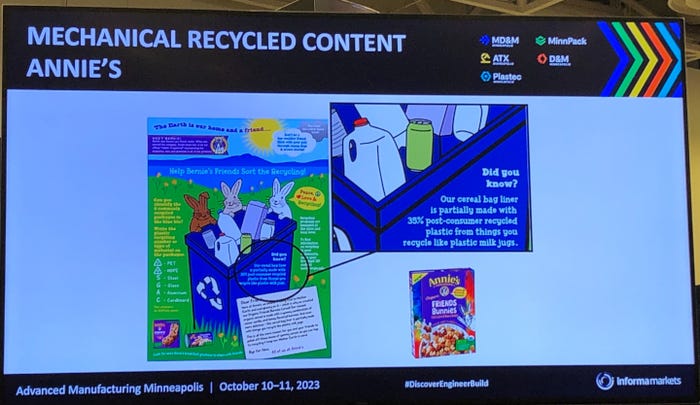

Another sustainability project, for Annie’s microwavable macaroni-and-cheese cups, focused on recyclability and compostability. Working closely with a molded-fiber packaging company, General Mills successfully transitioned the product line from polypropylene cups to fiber-based cups.

The vendor “had never printed before, so we had to go through all that learning,” Chmura said. In addition, the team went through about 14 different iterations of lid material to arrive at a structure that works properly with the new cup.

Packaging Digest, Lisa Pierce

Significantly, “we were able to get [the package] to pass the Western Michigan University paper-recycling test for recycling/repulpability, which is not easy,” Chmura recalled. The package is also BPI compostability-certified.

Material innovation and external collaboration.

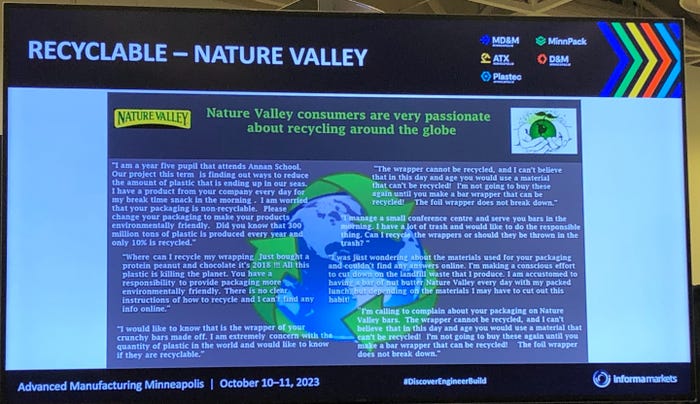

General Mills is particularly proud of transitioning its Nature Valley granola bar wrapper from non-recyclable film to recyclable polyethylene. This project combined the sustainability strategies of innovating a packaging material and partnering with suppliers.

For context, “films and flexible laminates are General Mills’ biggest sustainability challenge,” Chmura said. In the Nature Valley project, “we started to work way upstream of a converter. We started to work with film manufacturers and then eventually brought it to a converter.”

Packaging Digest, Lisa Pierce

After ruling out paper-based and compostable films for the Nature Valley application, “we ended up settling on polyethylene, [which] has now become the majority of our strategy in film and flexibles,” he added. The polyethylene film structure now used for Nature Valley granola bars is store drop-off recyclable.

Mobile app plays educational role.

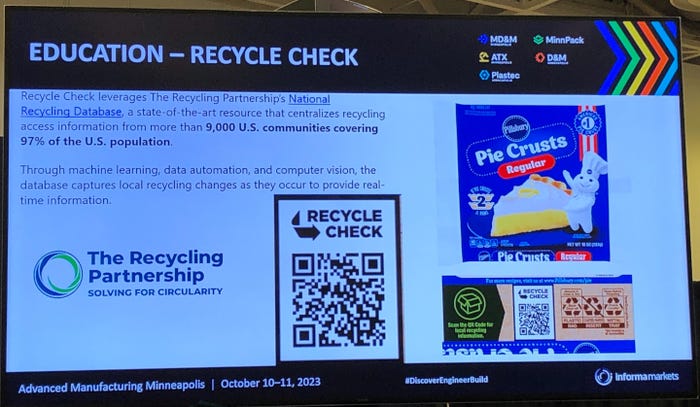

Education about recycling and other sustainability topics is another strategy for General Mills. In this category, Chmura demonstrated the Recycle Check mobile app, which lets consumers check the recyclability of a package by scanning an on-pack QR code.

Packaging Digest, Lisa Pierce

When they enter their ZIP code into the app, they quickly receive information about recycling options in their local community.

To power the app, “the Recycling Partnership created this amazing database, which basically covers 97% of the US population,” Chmura said, adding that machine learning, data automation, and computer vision enable the app to look for what’s changing in the recycling landscape. “It’s automatically updating itself.”

Building recycling infrastructure.

The final portion of the keynote focused on General Mills’ work with Myplas USA, a South Africa-based plastics recycler.

With funding from General Mills, Schwan’s, film manufacturer Charter Next Generation, Target, and Ecolab, Myplas opened a flexible-packaging recycling plant in Rogers, MN. The mechanical recycling facility began operations in December 2023.

The new plant is not a materials recovery facility (MRF), Chmura noted. “They’re taking baled film and converting that into pellets,” which Charter Next Generation will use to make new film products.

The plant will recycle/pelletize pallet wrap, shrink wrap, single-use shopping bags, and some food packaging.

General Mills’ participation in the Minnesota Myplas project underscores the importance of flexible packaging to the company, along with the pressing need to find recycling solutions for those materials.

Chmura revealed that film and flexible materials represent two-thirds of the company’s plastic packaging. “And within that, there [are more than] 150 unique flexible structures … that we need to get to a recyclable solution,” he said. “It’s a pretty big challenge.”

About the Author(s)

You May Also Like